Product Development Process

Feasibility Study

At the first step, we conduct in-depth re.search and technical analysis to evaluate theviability of your idea.

Our goal is to identify potential challengesoutline technical pathways, and propose ahigh-level product framework.

This process ensures that your vision isgrounded in practical, actionable strategiesbefore moving forward.

Engineer Validation

During this phase, we bring your concept tolife by developing a functional prototype.

Through industrial, mechanical, and elec-tronic design, we build a working Demo totest and verify core functionalities

By addressing technical risks early, we lay asolid foundation for further developmentand refinement.

Design Validation

Refine the product’s aesthetics and functionality with a focus on user experience andmanufacturability

This step includes finalizing CMF(Color, Material, Finish) details, conducting Design forManufacturability(DFM) analysis,and completing firmware and software integration.

We ensure that every detail aligns with bothdesignintent and production requirements,resulting in a product ready for production.

Production Validation

Final phase, involves a pilot production run tobridge the gap between prototype andfull-scale manufacturing

We produce a small batch of units using actualproduction processes and tools, allowing us toidentify and resolve any manufacturing issues.

This crucial step ensures a smooth transitionto volume production, guaranteeing that theproduct is market-ready, reliable, and deliveredwith consistent quality

Our Service Modules

Product Strategy

Functional Definition & PRD Input

Use Process Analysis

Mapping the user’s interaction with the product to optimize the experience.

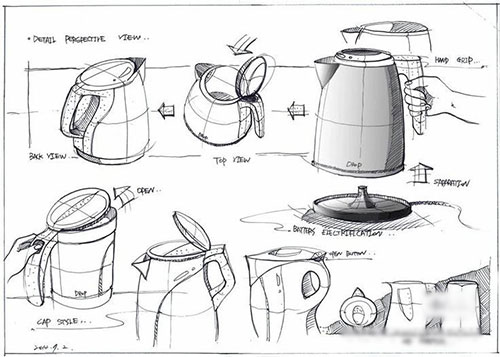

Product Sketching

Creating initial visual concepts to bring the idea to life.

Technical Pathway & Risk Assessment

Identifying key technical hurdles and proposing viable solutions to mitigate development risks.

Cost Estimate & Timeline Projection:

Providing early projections for development, manufacturing, and a high-level project timeline.

Product Design

Industrial Design(lD)

Crafting the aesthetic, ergonomic, and user-centric form of the product.

Mechanical Design

Engineering the internal components and structures for strength, function

Rapid Prototyping

Building physical models for form, fit, and function testing.

Mold Flow Analysis & Mold Design

Designing precision molds for consistent and efficient production.

Design for Manufacturability (DfM)

Continuously refining the design to simplify manufacturing, reduce costs, and ensure quality.

Mass Production Support

Overseeing the manufacturing process to ensure quality and fidelity to the design.

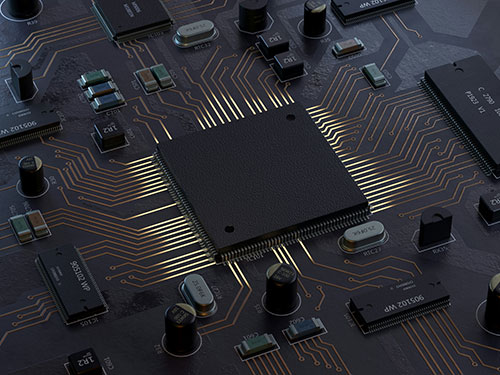

Hardware Design

Component Selection

Sourcing optimal electronic parts for performance, cost, and availability while defining the overall system architecture.

Circuit Schematic Design

Creating the blueprint for the electronic system.

PCB Layout

Designing the physical circuit board for signal integrity and manufacturability.

PCB Prototype&Assembly (PCBA)

Fabricating and assembling board prototypes for testing.

Firmware Design & Debugging

Writing the low-level code that controls the hardware and debugging for flawless operation.

System Integration & Functional Testing

Integrating electronics into a working model for comprehensive validation.

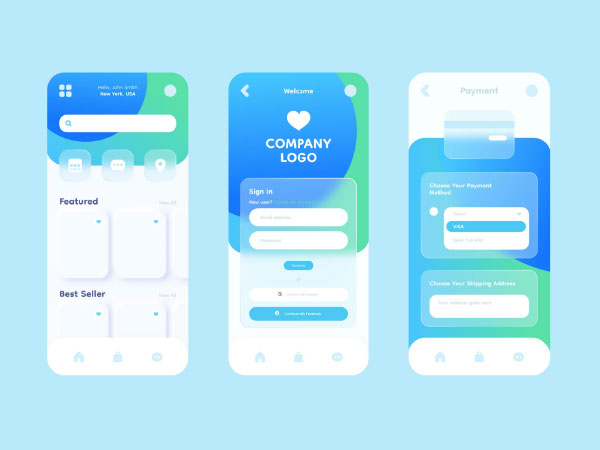

Software Design

UserInterface(Ul)Design

Designing user-friendly interfaces based on workflow and usability principles.

Mobile Application Development (iOS & Android)

Building native or cross-platform applications for iOS and Android.

Desktop & Web Application Development

Creating software for Windows, macOS, or web-based platforms.

Embedded Systems & IoT Software

Developing software that runs directly on the product’s hardware, including drivers, communication protocols (Wi-Fi, Bluetooth), and IoT cloud integration.

Software Technical Support

Providing ongoing maintenance, updates, feature enhancements, and troubleshooting.

Package design

Brand Visual ldentity

Establishing your brand’s visual language, including logo usage, color palette, typography and so on.

Package Structural Design & DFM

Engineering the physical structure for maximum protection, shelf impact, and manufacturing efficiency

Cosmetic & Graphic Design

Designing the outer look and feel that aligns with your brand and communicates key product information.

Packaging Prototype

Creating physical samples to test design, durability, drop-test performance, and assembly.

Mass Production

Sourcing materials and suppliers, and managing the production with manufacturers to ensure quality and consistency.

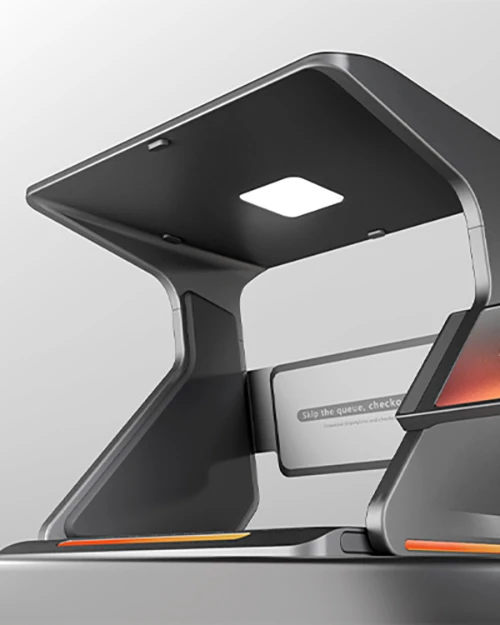

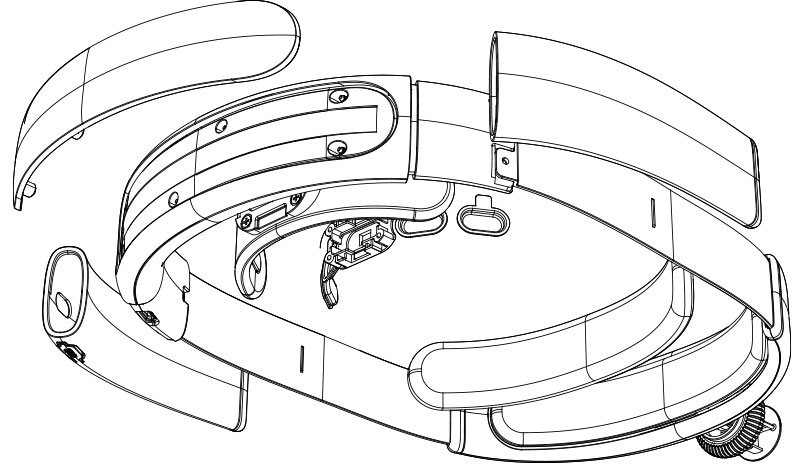

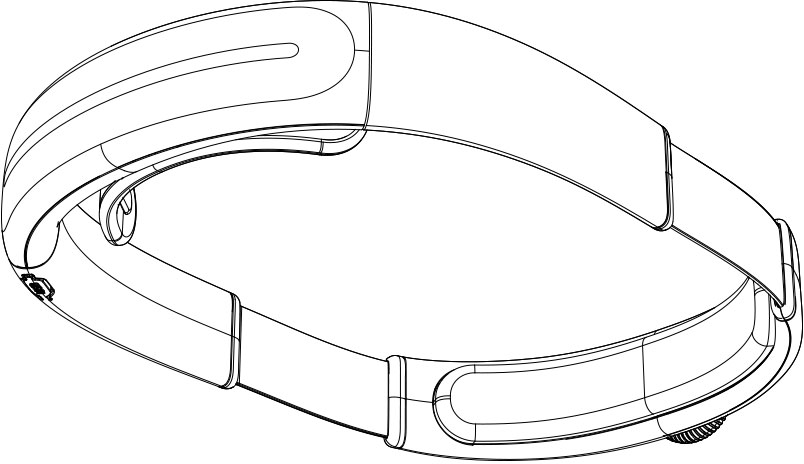

Featured Projects