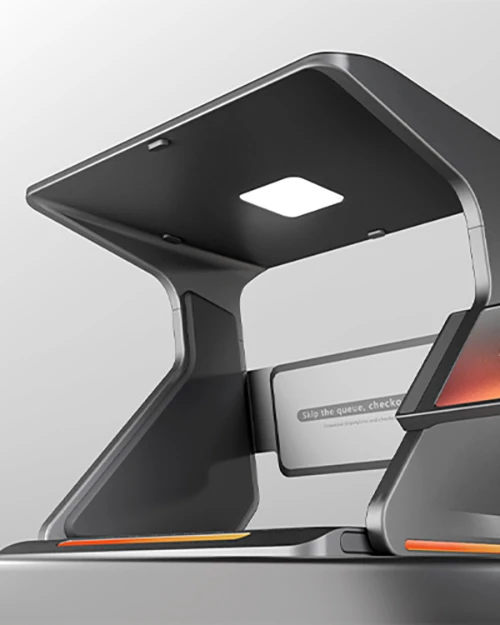

Outdoor speakers

Client country: China

Services: industrial design|machine design|functional prototyping

Project Background

Against the backdrop of the booming outdoor events like large-scale parties and music festivals, there has been a surging demand for high-power, highly adaptable outdoor audio devices. Existing portable speakers generally suffer from insufficient sound pressure and limited sound field coverage, failing to meet the amplification needs of large gatherings. Developed to address this pain point, this outdoor speaker fills the gap in audio equipment for large-scale outdoor entertainment scenarios with its powerful sound and stable performance.

Solution

Core Objectives

Address the four core pain points of insufficient sound pressure, uneven sound field coverage, short battery life, and poor environmental adaptability in large-scale outdoor parties and entertainment events, and create a professional-grade mobile audio device tailored for multi-person gathering scenarios.

Specific Solutions

1.High-Power Acoustic SolutionEquipped with dual 10-inch subwoofers and high-frequency horn units, it delivers a peak power of 300W, supports stereo/mono dual-mode switching, and achieves a sound field coverage radius of up to 50 meters, meeting the amplification needs of large parties with 50–200 people. Built-in DSP sound chip comes with preset scene modes including party, rock and folk, automatically optimizing sound quality to avoid distortion.

2.Long-Lasting Battery & Fast Charging SolutionFitted with a large-capacity 12000mAh lithium battery, it supports continuous playback for ≥12 hours. It features 20W fast-charging technology—2 hours of charging provides 8 hours of usage. An additional solar panel enables emergency charging, making it suitable for outdoor scenarios without power supply.

3.Portability & Stability SolutionAdopts a lightweight alloy frame paired with wear-resistant rubber wheels, with the cabinet weight controlled within 15kg for easy single-person towing and movement. The bottom is equipped with retractable fixed brackets and wind rope interfaces, capable of withstanding level 5 outdoor winds and preventing equipment tipping.

4.Smart Connectivity & Triple Protection SolutionSupports Bluetooth 5.3, NFC quick pairing and wired microphone connection, compatible with multi-device series connection for stereo expansion. The body adopts IPX5 waterproof and dustproof design, which can cope with complex outdoor environments such as rainy days and sandy dust.

Design Process Outline For Outdoor Large-Scale Party Speak

Core Orientation: Focus on “high power, strong adaptability, stable performance, and easy portability” to meet the needs of large-scale outdoor partyscenarios

I. Preparatory Stage (1-2 Weeks)

- Requirement Analysis: Clarify core requirements (300W+ power, 50m sound field coverage, ≥12-hour battery life, etc.) and secondary requirements (multiple sound modes, multi-device connectivity, etc.)

- Competitor and Technology Research: Analyze the advantages and disadvantages of mainstream high-power outdoor speakers, and verify the feasibility of core technologies such as DSP chips and lithium batteries

- Project Approval and Planning: Output “Requirement Specification Manual”, clarify parameters, budget and time nodes, and set up a cross-functional design team

II. Core Design Stage (3-4 Weeks)

- Acoustic Design (1.5 Weeks): Determine speaker selection and layout plan, preset scene sound modes, and output acoustic design-related documents

- Industrial and Structural Design (2 Weeks): Complete exterior portability design, IPX5 protection and stable structural design, and output exterior renderings and structural drawings

- Electronic and Circuit Design (1.5 Weeks): Design core circuits such as power amplifier, fast charging and connectivity, add safety protection, and output circuit design-related documents

III. Prototype Production and Verification Stage (2-3 Weeks)

- Prototype Production: Manufacture functional prototypes to verify the compatibility of various components

- Multi-Dimensional Testing: Conduct acoustic, performance, environmental adaptability and safety tests

- Prototype Iteration: Optimize and adjust for test issues until design indicators are met

IV. Mass Production Preparation and Implementation Stage (2-3 Weeks)

- Design Finalization: Confirm the final plan and output mass production drawings, BOM list and other documents

- Supply Chain Connection: Connect with core suppliers and conduct small-batch sampling to verify consistency

- Production Line Debugging: Build production lines, optimize processes and formulate quality inspection standards

- Small-Batch Mass Production: Complete small-batch production and full performance re-testing, and launch large-scale production