ABOUT

US

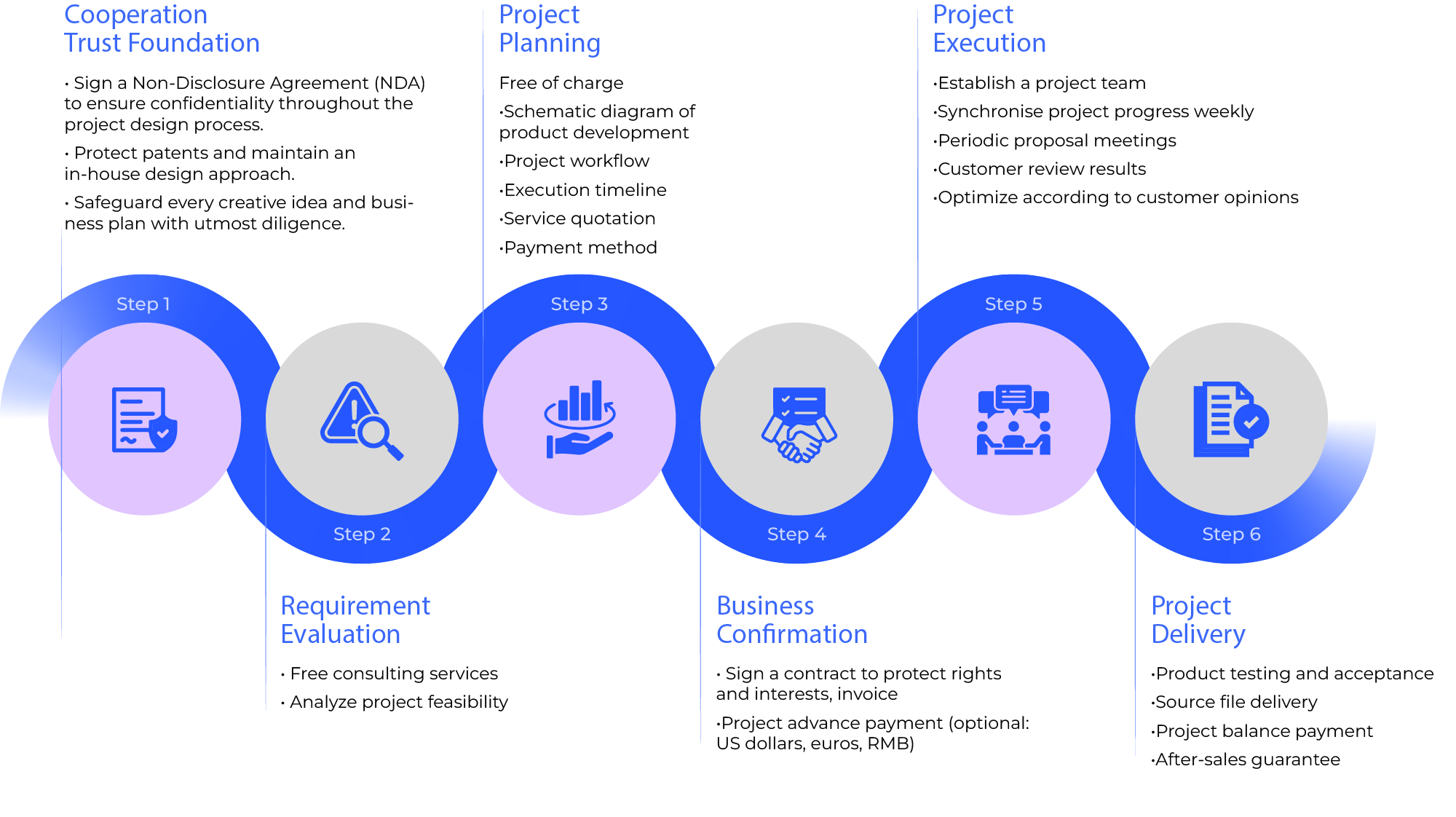

Product Development Process

Feasibility Study

At the first step, we conduct in-depth re.search and technical analysis to evaluate theviability of your idea.

Our goal is to identify potential challengesoutline technical pathways, and propose ahigh-level product framework.

This process ensures that your vision isgrounded in practical, actionable strategiesbefore moving forward.

Engineer Validation

During this phase, we bring your concept tolife by developing a functional prototype.

Through industrial, mechanical, and elec-tronic design, we build a working Demo totest and verify core functionalities

By addressing technical risks early, we lay asolid foundation for further developmentand refinement.

Design Validation

Refine the product’s aesthetics and functionality with a focus on user experience andmanufacturability

This step includes finalizing CMF(Color, Material, Finish) details, conducting Design forManufacturability(DFM) analysis,and completing firmware and software integration.

We ensure that every detail aligns with bothdesignintent and production requirements,resulting in a product ready for production.

Production Validation

Final phase, involves a pilot production run tobridge the gap between prototype andfull-scale manufacturing

We produce a small batch of units using actualproduction processes and tools, allowing us toidentify and resolve any manufacturing issues.

This crucial step ensures a smooth transitionto volume production, guaranteeing that theproduct is market-ready, reliable, and deliveredwith consistent quality

Production Capacity

The foundation of our DFM is our manufacturing capabilities. We have significant production resources, so wedesign from a production perspective. Our industry-leading intelligent manufacturing equipment, coupled with ahighly experienced production management team, enables us to deliver comprehensive production solutions tai.lored to innovative products.

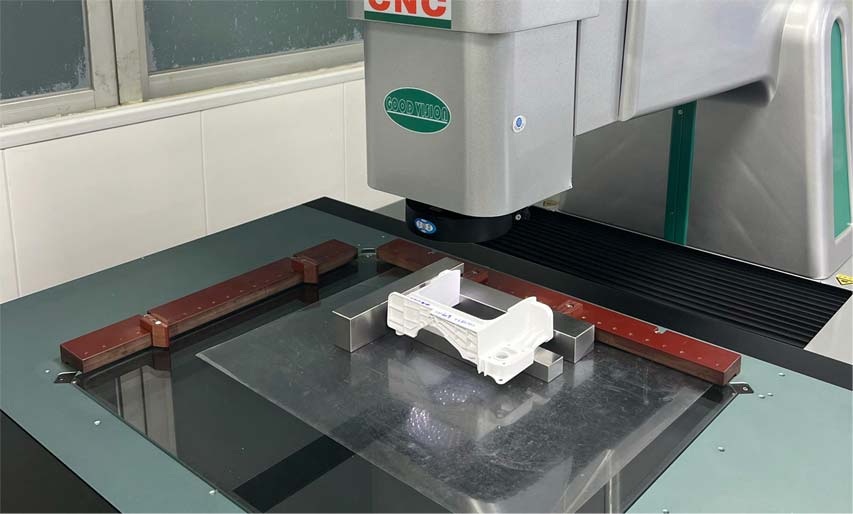

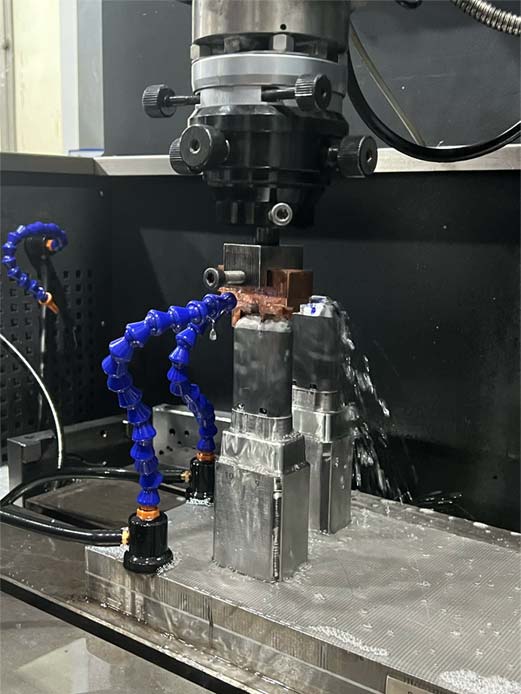

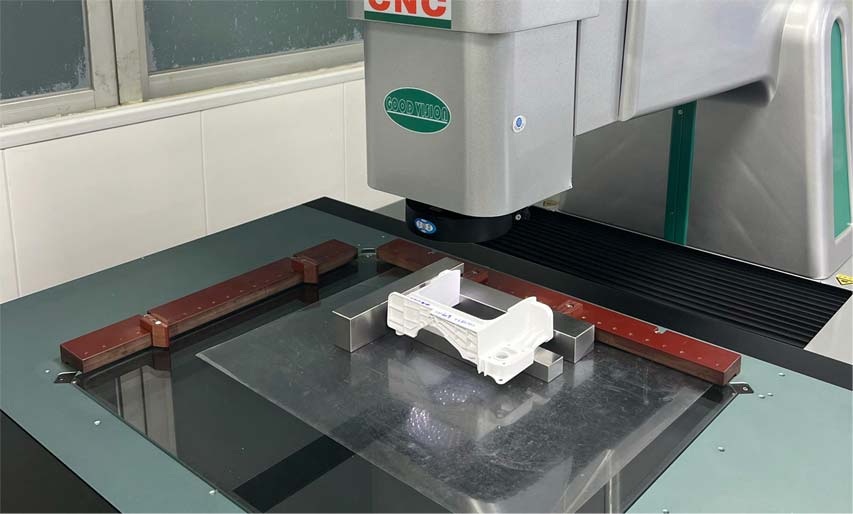

Prototype

Our prototype center boasts advanced equipment, including 3D printers, CNC machines, and vacuum molding machines. With more than 20 seasoned professionals on our team, we specialize in creating plastic prototypes, metal prototypes, and various other types. Leveraging our exquisite craftsmanship and efficient services, we deliver precise prototype solutions to expedite product development and market introduction

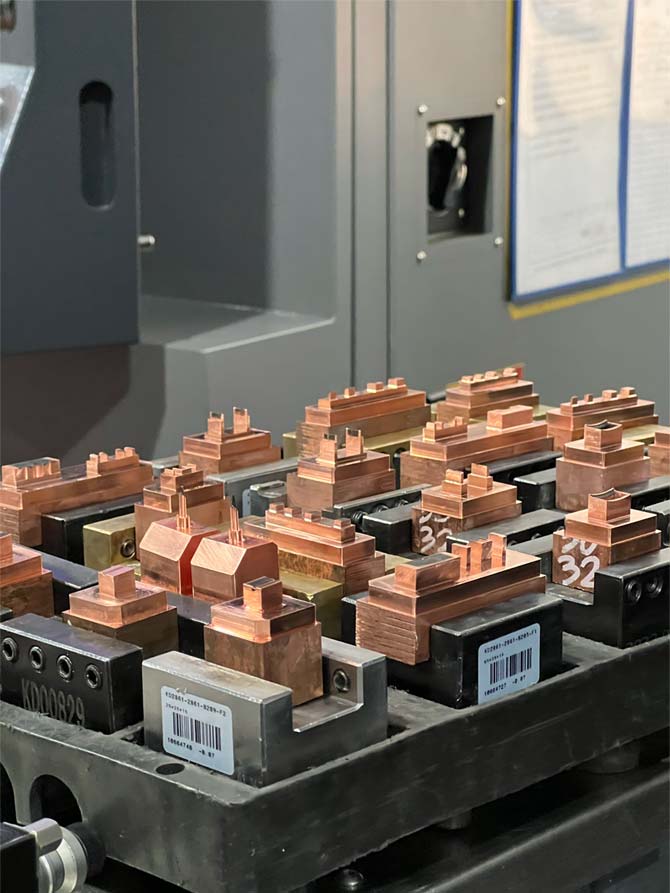

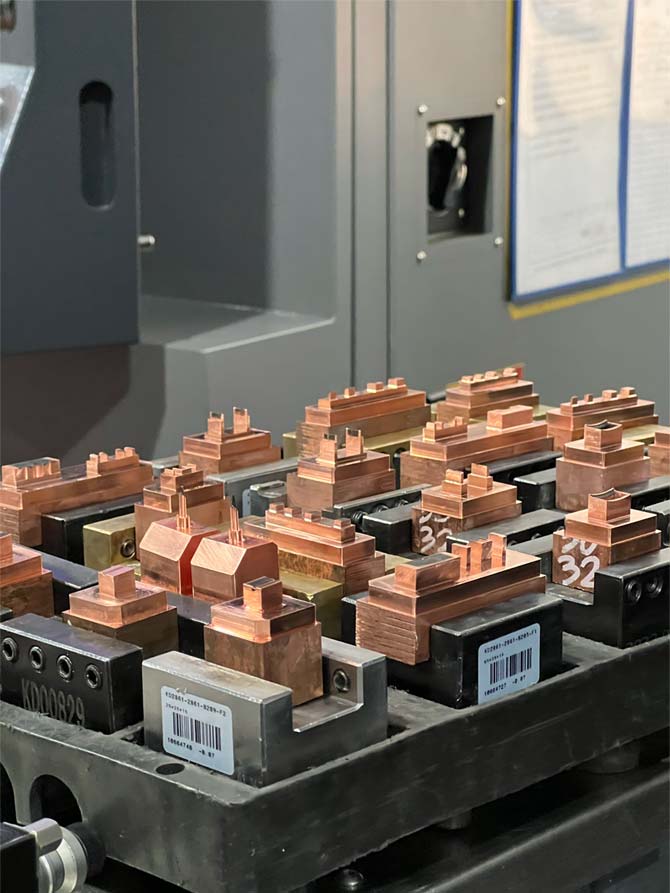

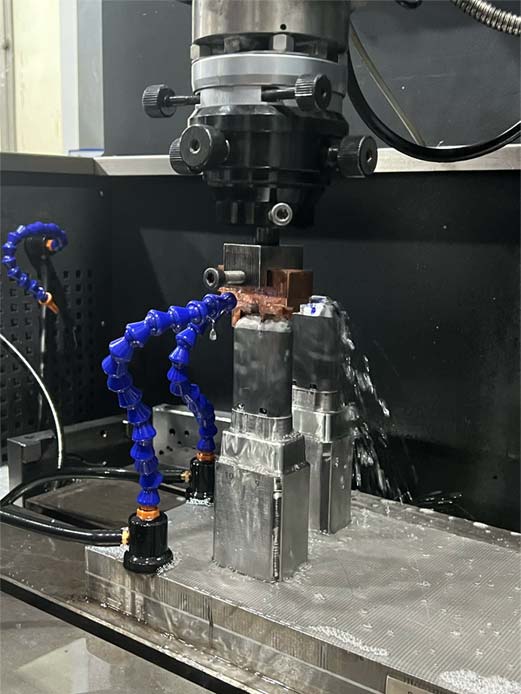

Mould

Mold workshop is equipped with state-of-the-art processing equipment, including high-precision CNC machine tools and EDM machines. Our professional team consists of over 40 highly skilled members, specializing in the manufacture of injection molds and die-casting molds. These molds are extensively utilized in various sectors such as automotive, electronics, and home appliances.

Main Equipment:

- CNC Spark Machines (SODICK, etc.)

- CNC Slow Wire (SODICK)

- CNC High-Speed CNC (DMG, MAKINO)

Injection

Molding

Our injection molding workshop is equipped with numerous advanced injection molding machines of various specifications, capable of accommodating a wide range of product sizes. The workshop features professional mold installation and debugging equipment, alongside an automated material conveying system. Our dedicated technical team, comprising 60 skilled professionals, rigorously oversees the production process to ensure the highest quality of each injection molding product.

Key Features:

1.Injection Molding Equipment:

- 47 injection molding machines

2.Distribution of Injection Molding Machines:

- One 1250-ton injection molding machine

- One 400-ton injection molding machine

- Twenty 160-ton to 250-ton injection molding machines

3.Injection Accuracy:

- Injection position accuracy up to 0.1MM

- Product size accuracy controlled within 0.01MM

- Advanced power system boosts injection speeds to 130-140MM/S, enabling the injection of thin-walled plastic products (0.2~0.5mm)

Spraying

The spraying workshop is designed as a 10,000-level dust-free environment. Our main production process utilizes a fully automated two-coat and two-bake spraying technique. The automatic line is equipped with high-quality spray gun equipment and high-energy UV light curing equipment.

Key Features:

1.Spraying Equipment:

- One two-coat and two-bake automatic spraying line

- Two robot large-piece spraying lines

- One printing line

- Twenty pad printing machines

2.Production Capacity:

- Smart wearable spraying: 5 million pieces per month

- Robot small and medium-sized part spraying: 1 million pieces per month

- Robot large-piece spraying: 30,000 pieces per month

- Printing: 4 million pieces per month

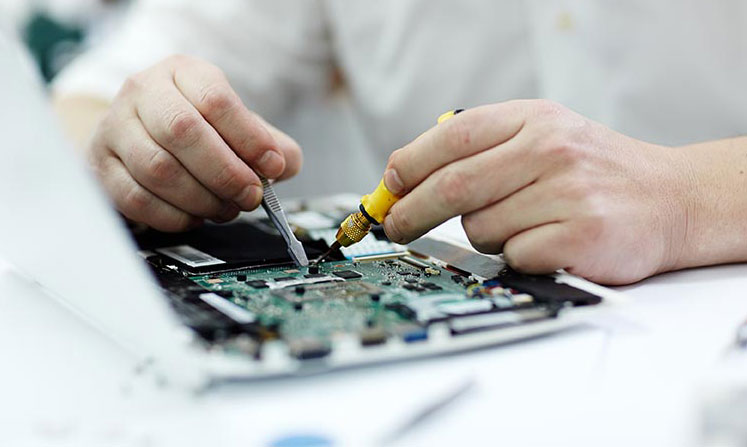

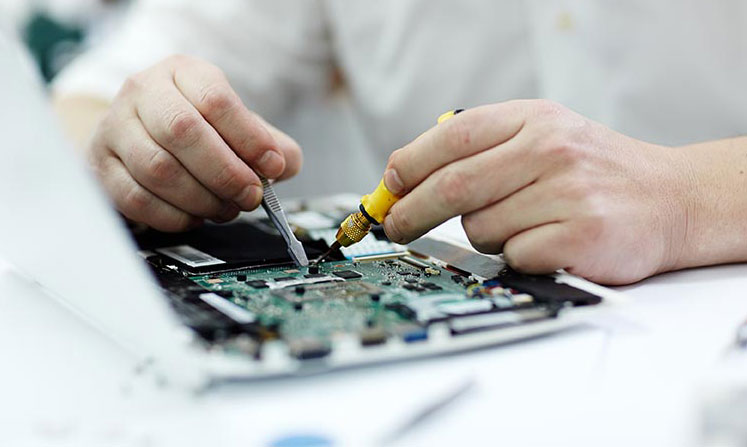

Assembly

Our company currently operates two 100,000-level dust-free assembly workshops and seven bidirectional assembly lines, all housed within a newly constructed four-story supporting factory building, totaling 16,000m². This infrastructure is designed to meet the increasing demand for orders.

Key Features:

1.Assembly Department

- Four assembly lines

- Main production includes customized machines, Y10 series, Y20 series

- One Y50 series customized line

- Three bidirectional assembly lines for other models

2.Assembly Department

- Primarily a dedicated production line for the 150CM large machine series

- Two bidirectional assembly lines for other models

3.Assembly Capacity:

- Assembly Department 1: 250,000 finished units per month

- Assembly Department 2: 130,000 finished units per month

Testing

Each robot product we manufacture undergoes rigorous testing to ensure reliable product quality. Our testing laboratory is equipped with a comprehensive range of advanced equipment to perform various assessments.

Testing Equipment:

- Projector

- Colorimeter

- Halogen Lamp Moisture Meter

- Impact Tester

- Tensile/Bending/Strength Tester

- Vicat Thermal Deformation Tester

- RCA Paper Tape Tester

- Waterproof Tester

- Friction Tester

- Flame Flow Rate Velocity Apparatus

- Horizontal and Vertical Combustion Tester

- Hardness Tester

Our prototype center boasts advanced equipment, including 3D printers, CNC machines, and vacuum molding machines. With more than 20 seasoned professionals on our team, we specialize in creating plastic prototypes, metal prototypes, and various other types. Leveraging our exquisite craftsmanship and efficient services, we deliver precise prototype solutions to expedite product development and market introduction

Mold workshop is equipped with state-of-the-art processing equipment, including high-precision CNC machine tools and EDM machines. Our professional team consists of over 40 highly skilled members, specializing in the manufacture of injection molds and die-casting molds. These molds are extensively utilized in various sectors such as automotive, electronics, and home appliances.

Main Equipment:

- CNC Spark Machines (SODICK, etc.)

- CNC Slow Wire (SODICK)

- CNC High-Speed CNC (DMG, MAKINO)

Our injection molding workshop is equipped with numerous advanced injection molding machines of various specifications, capable of accommodating a wide range of product sizes. The workshop features professional mold installation and debugging equipment, alongside an automated material conveying system. Our dedicated technical team, comprising 60 skilled professionals, rigorously oversees the production process to ensure the highest quality of each injection molding product.

Key Features:

1.Injection Molding Equipment:

- 47 injection molding machines

2.Distribution of Injection Molding Machines:

- One 1250-ton injection molding machine

- One 400-ton injection molding machine

- Twenty 160-ton to 250-ton injection molding machines

3.Injection Accuracy:

- Injection position accuracy up to 0.1MM

- Product size accuracy controlled within 0.01MM

- Advanced power system boosts injection speeds to 130-140MM/S, enabling the injection of thin-walled plastic products (0.2~0.5mm)

The spraying workshop is designed as a 10,000-level dust-free environment. Our main production process utilizes a fully automated two-coat and two-bake spraying technique. The automatic line is equipped with high-quality spray gun equipment and high-energy UV light curing equipment.

Key Features:

1.Spraying Equipment:

- One two-coat and two-bake automatic spraying line

- Two robot large-piece spraying lines

- One printing line

- Twenty pad printing machines

2.Production Capacity:

- Smart wearable spraying: 5 million pieces per month

- Robot small and medium-sized part spraying: 1 million pieces per month

- Robot large-piece spraying: 30,000 pieces per month

- Printing: 4 million pieces per month

Our company currently operates two 100,000-level dust-free assembly workshops and seven bidirectional assembly lines, all housed within a newly constructed four-story supporting factory building, totaling 16,000m². This infrastructure is designed to meet the increasing demand for orders.

Key Features:

1.Assembly Department

- Four assembly lines

- Main production includes customized machines, Y10 series, Y20 series

- One Y50 series customized line

- Three bidirectional assembly lines for other models

2.Assembly Department

- Primarily a dedicated production line for the 150CM large machine series

- Two bidirectional assembly lines for other models

3.Assembly Capacity:

- Assembly Department 1: 250,000 finished units per month

- Assembly Department 2: 130,000 finished units per month

Each robot product we manufacture undergoes rigorous testing to ensure reliable product quality. Our testing laboratory is equipped with a comprehensive range of advanced equipment to perform various assessments.

Testing Equipment:

- Projector

- Colorimeter

- Halogen Lamp Moisture Meter

- Impact Tester

- Tensile/Bending/Strength Tester

- Vicat Thermal Deformation Tester

- RCA Paper Tape Tester

- Waterproof Tester

- Friction Tester

- Flame Flow Rate Velocity Apparatus

- Horizontal and Vertical Combustion Tester

- Hardness Tester

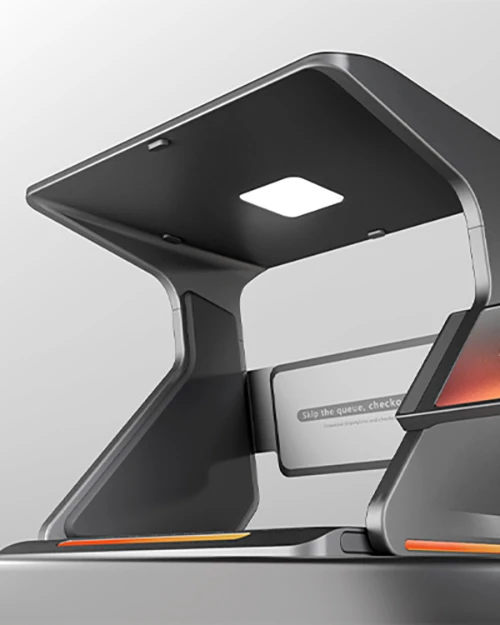

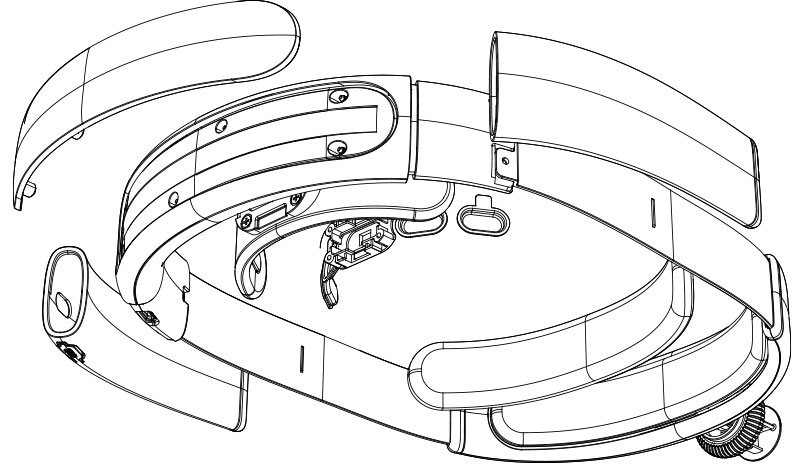

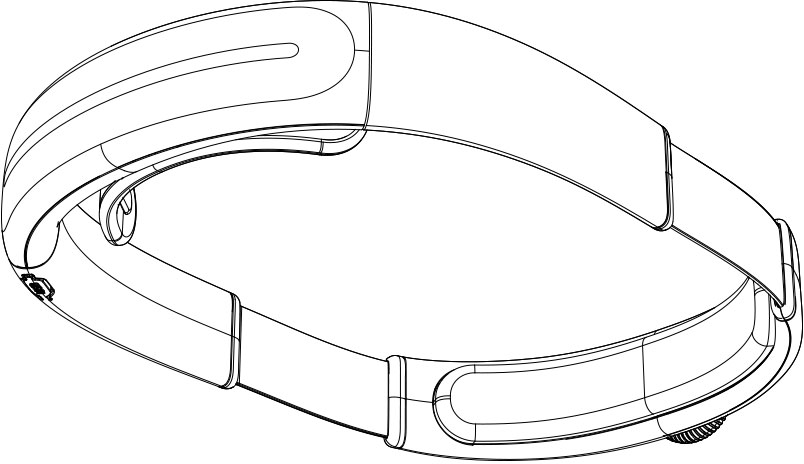

Featured Projects

FAQ

How is my intellectual property protected?

Before sharing information about your products or company, we sign an NDA (Non-Disclosure Agreement).

We will do our best to cooperate in protecting intellectual property

What service do you offer?

The services we provide can be devided into 4 parts:

- DESIGN: Industrial Design;Mechanical Desian; Package Design

- ENGINEERING: DFM: Hardware Development; Firmware Development; Software Development: loT solutions

- PROTOTYPING: Rapid Prototyping; Functional Prototyping; Material Testing

- MANUFACTURlNG: injection Molding Service; Small Batch Production; Supply Chain Management; Production Management

What is a typical development timeframe?

The development of hardware products is time-consuming because updates and iterations are difficult and costly. Therefore, we will do a lot of work to ensure better implementation of the productDepending on the product, the development time will be different, Taking common consumer prod.ucts as an example, it takes about 6-8 months from design to mass production.Feel free to contact us for details.

How much does product development cost?

It depends on the type of products and what services you need.

Please write down your requirement and we will contact you as soon as possible.