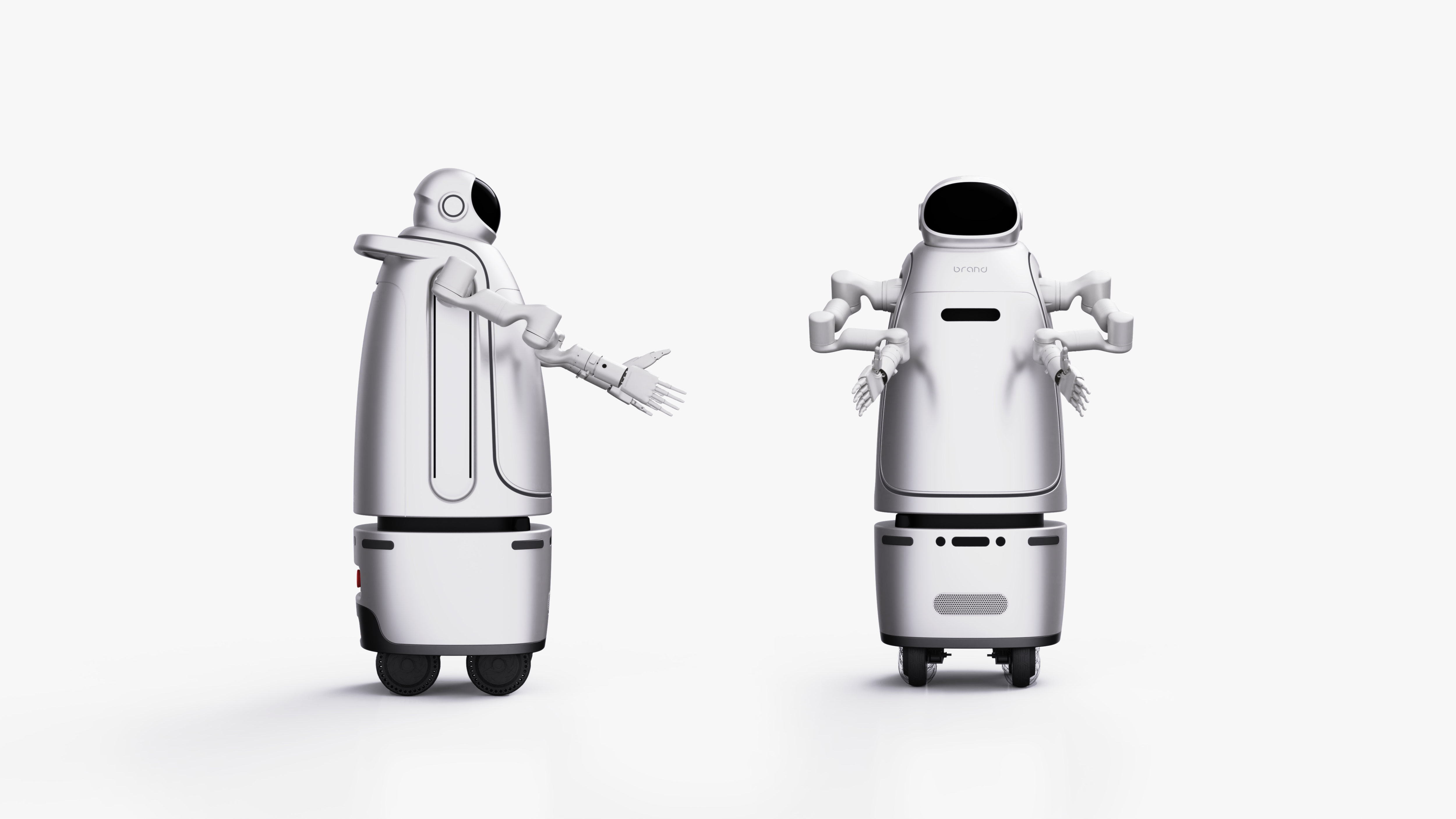

Intelligent Cleaning Robot

Client country: Hong Kong

Services: industrial design|machine design|functional prototyping|mold development

Project Background

Public and commercial toilet cleaning has long faced challenges such as labor shortages, high labor intensity, high risk of contact infection, and difficulty in standardization.

This project aims to develop an autonomous robot capable of operating within confined toilet cubicles, replacing manual labor in the cleaning process, making cleaning safer, more stable, and enabling traceable quality control.

Solution

Design Innovations

A. Multifunctional Robotic Arm + Tool-Compatible Architecture

- Two multi-degree-of-freedom robotic arms (capable of flexibly using human cleaning tools: brushes, cloths, spray guns, etc.) to perform actions such as picking, rotating, pressing, and wiping.

- Standardized tool interfaces (quick-change), compatible with commercially available cleaning tools, reducing costs and maintenance complexity.

B. Compact Body and Concealed Water/Wastewater Management

- Built-in removable clean water tank and wastewater reservoir, maintaining a clean appearance and facilitating on-site filling and cleaning.

- Modular internal layout for easy maintenance and tool storage, adaptable to narrow cubicles and common toilet layouts.

C. Fully Autonomous Navigation and Safe Interaction

- Multi-sensor fusion (topology/laser/depth camera) enables indoor autonomous positioning, obstacle avoidance, and precise location of the sink/toilet.

- Human-machine safety strategies (collision buffering, force limitation, emergency stop), with voice/screen display feedback indicating the operation status.

Intelligent Cleaning Robot Design Process

Step 1-Needs Analysis and Concept Screening

- On-site Survey: Measure cubicle dimensions, record obstacles and cleaning actions, and interview cleaners to collect information on commonly used tools and pain points.

- Determine Acceptable Requirements: Transform “operating in confined spaces, tool compatibility, modular water tank, ease of maintenance, low failure rate, and safety limits” into measurable indicators.

- Concept Generation and Scoring: Produce multiple chassis/body/arm configurations and quickly score and screen them using a matrix of “accessibility/reliability/cost/maintenance/safety”.

Step 2-Detailed Design and Prototype Verification

- Key Detailed Design Considerations: Determine the modular body, ensure compatibility of the robotic arm’s end effector with commonly used tools, and ensure the chassis kinematics meet minimum turning radius and positioning accuracy.

- Prototype Fabrication: Assemble the robotic arm, hydraulic system, and chassis according to the design.

- Verification Items: Arm control and gripping stability, hydraulic system sealing and wastewater recovery, wiping/spraying effectiveness, battery life, and collision safety.