Curved ceramic cooktop

Client country: China

Services: industrial design|machine design|functional prototyping|packaging design

Project Background

Today’s small home appliances prioritize both aesthetics and practicality, while traditional ceramic cooktops often feature a flat, rigid design. This curved glass ceramic cooktop project focuses on “soft aesthetics + efficient heating,” addressing the lightweight and decorative needs of modern kitchens. It uses curved glass to enhance the curved surface while optimizing heating efficiency, filling a market gap for sophisticated small kitchen appliances.

Solution

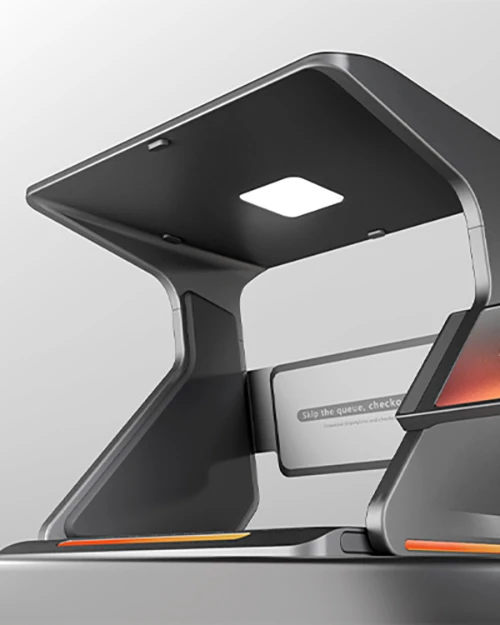

Solution for Curved Glass Induction Cooktop

A. Pure Mechanical Architecture Design

- High-temperature resistant curved tempered glass panel (complies with GB 4806.5-2016 standard, heat-resistant up to 800°C without cracking)

- Integrated seamless curved craftsmanship (no splicing gaps, spill-proof, easy to wipe, and oil-stain resistant)

- Microcrystalline ceramic heating plate (resistant to rapid temperature changes, no performance degradation after 1000 hours of continuous operation)

B. Scene Adaptation Optimization

- Curved energy-concentrating design (heat is concentrated without diffusion, heating efficiency is 25% higher than traditional induction cooktops)

- Lightweight and portable body (total weight ≤1.2kg, equipped with non-slip silicone base, suitable for kitchen/camping scenarios)

- Wide power adjustment range (200W-2200W, compatible with multiple uses such as tea brewing, milk heating, and pan-frying)

C. Experience & Aesthetic Design

- Curved streamer touch control (invisible touch buttons embedded in the glass panel, sensitive operation and anti-misoperation)

- Gradient curved appearance (customizable Morandi color system, suitable for modern home styles)

- Low-noise operation structure (working noise ≤40dB, avoiding kitchen noise interference)

Design Process of the Curved Glass Electric Ceramic Cooktop

Demand Research: Analyze market pain points (low aesthetic appeal and heat dissipation issues of traditional electric ceramic cooktops), conduct research on user scenarios (home/camping) and competitor parameters, and clarify the core direction of “curved energy concentration + lightweight aesthetics”

Concept Design: Output curved shape schemes (including energy-concentrating structure/touch interaction), and finalize the prototype of “seamless curved surface + invisible touch control” combined with material testing (high-temperature resistance of tempered glass).

- Engineering R&D: Advance simultaneously:

- Structure: Integrated curved glass forming process + microcrystalline heating plate adaptation;

- Function: Circuit debugging for power adjustment/anti-misoperation touch control;

Prototype Verification: Produce prototypes, test indicators such as high-temperature resistance, heatingefficiency, and noise, and optimize the grip of the curved surface and the stability of the non-slip base.

Mass Production Launch: Determine gradient appearance color schemes, cooperate with the supply chain to realize mass production of the seamless curved surface process, and complete safety certification (GB standard) simultaneously.