Medical-Grade Smart Comb

Client country: China

Services: Industrial Design & Mechanical Innovation

Project Background

As a 15-year biotech leader in scalp care, KimDai identified critical flaws in traditional roller-ball systems through quantitative lab tests and user behavior analysis:

30% Active Ingredient Loss: Mechanical friction and oxidation in roller-ball structures.

68.6% Absorption Rate: Rigid designs failed to adapt to scalp curvature.

OPD-Design’s medical-grade industrial design framework reimagined these challenges, targeting >90% delivery efficiency while transforming a clinical tool into a luxury self-care device.

Solution

TRIZ-Driven Mechanical Innovation

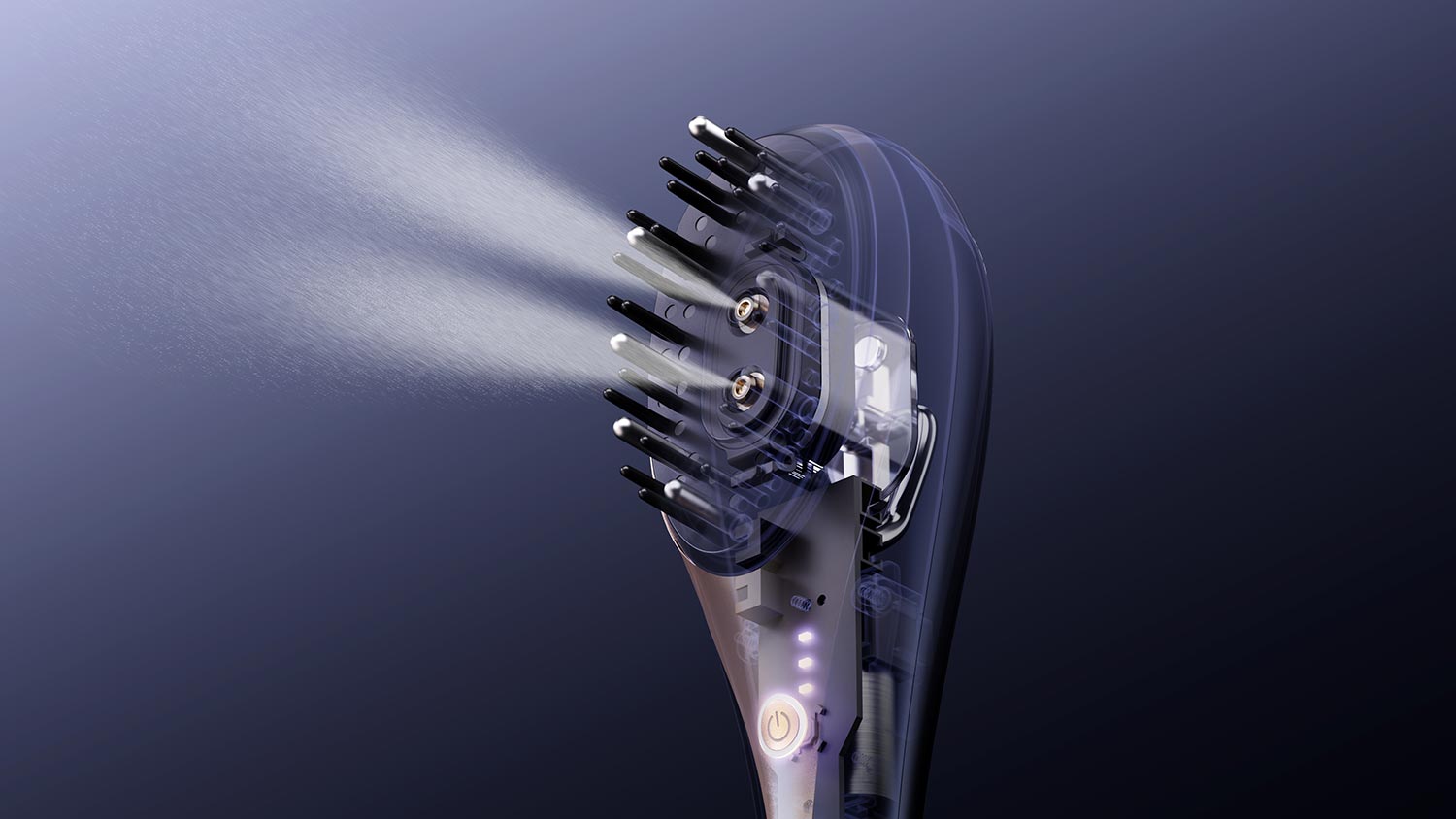

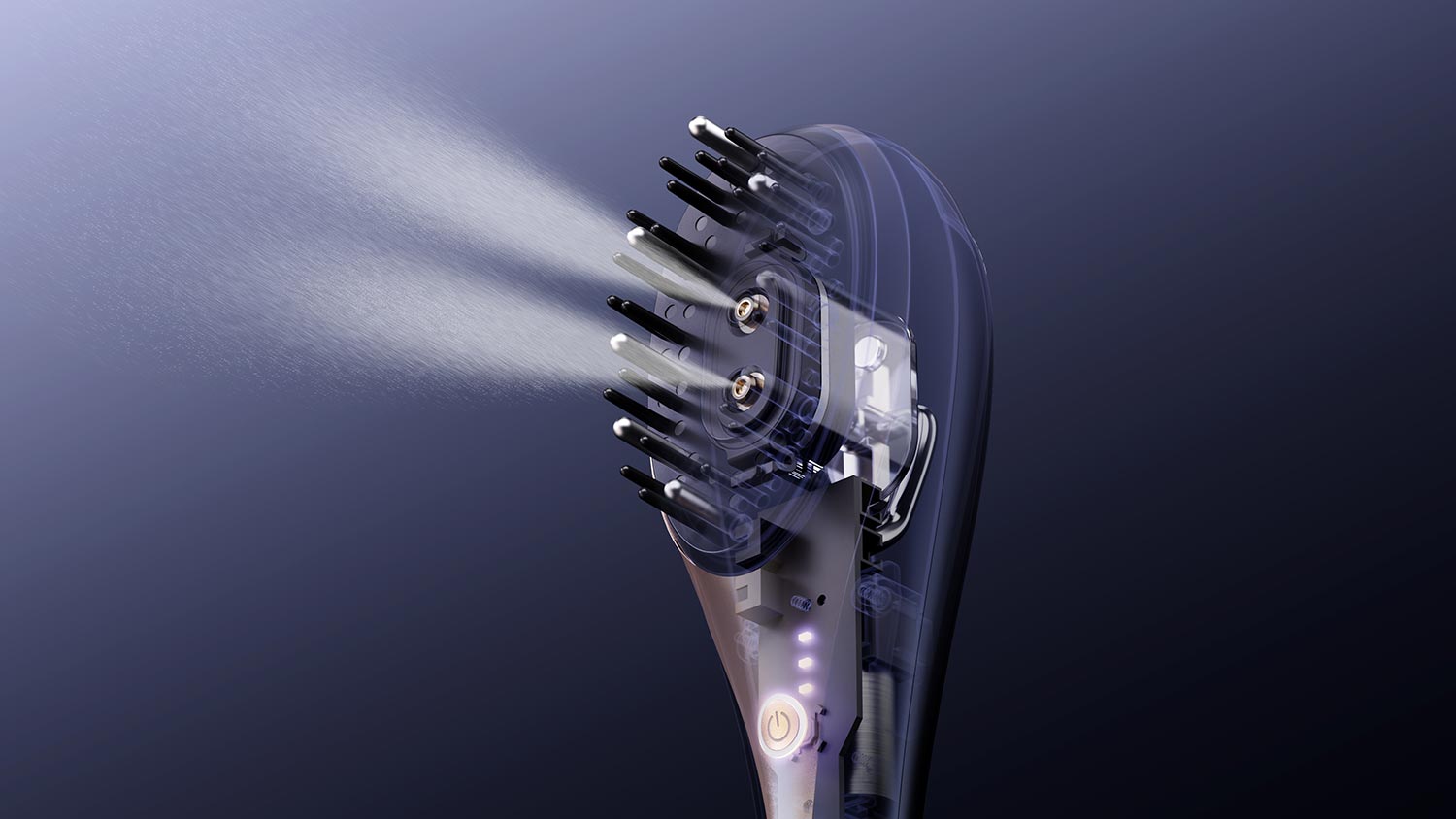

MEMS Atomization Core: Replaced roller-balls with microelectromechanical systems for 8μm mist precision (vs. 150μm droplets in traditional systems).

Self-Cleaning Mechanism: 20,000rpm titanium blade (Patent ZL2023XXXXXX) prevents clogs in high-viscosity formulas.

Ergonomic Scalp Mapping: 16-point pressure sensors adjust mist density for Asian scalp curvatures.

Step 1-Industrial Design

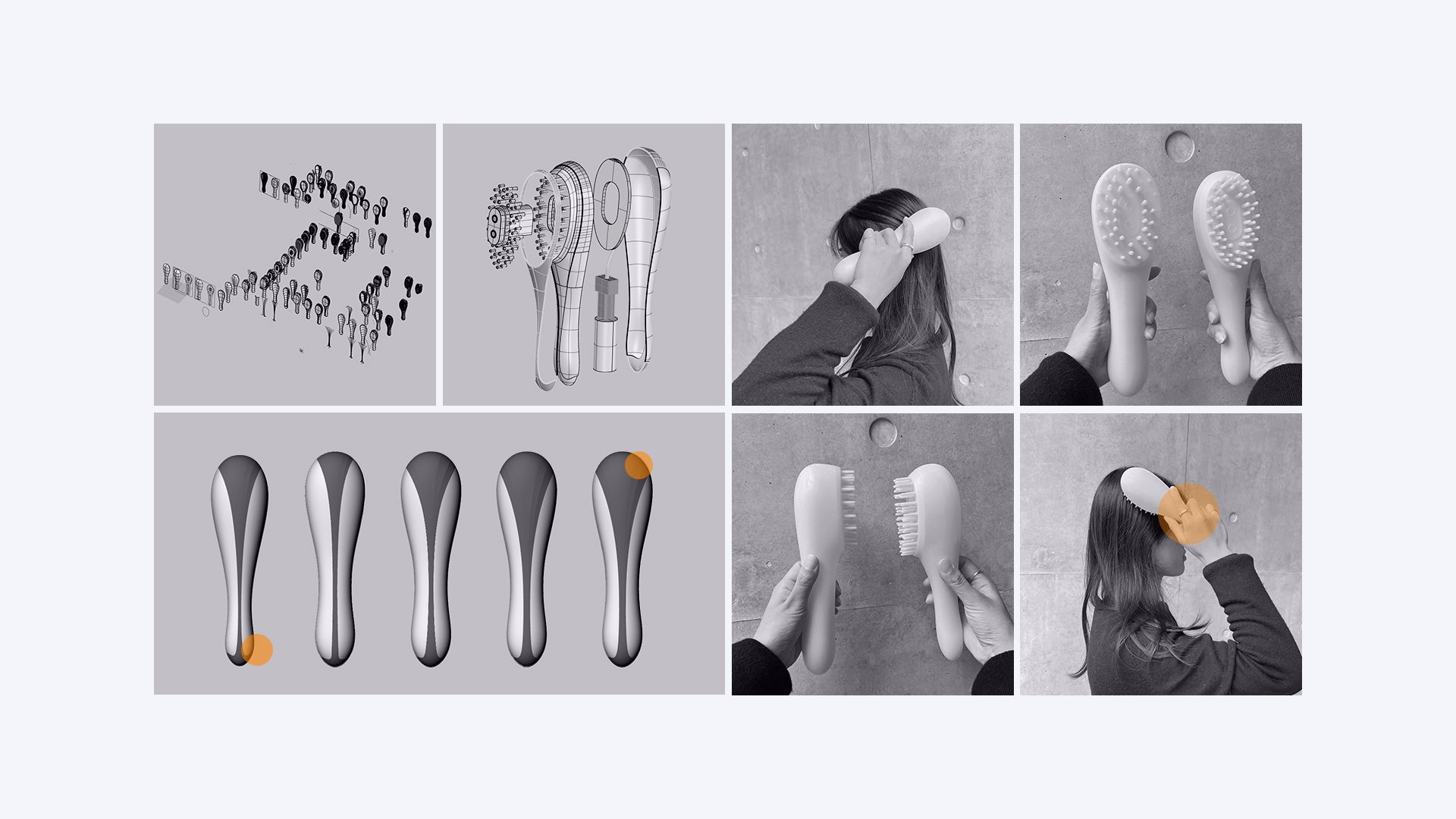

1. Cross-Disciplinary Technology Mapping

Using TRIZ innovation methodology, we integrated microfluidics, mechanical dynamics, and electronic engineering:

Mechanical Design Breakthrough: Replaced traditional roller-ball mechanisms with MEMS-based microelectromechanical systems;

Industrial Design Empowerment: Defined a 47° golden grip angle based on scalp curvature big data (100,000+ Asian user models).

2. Function-Form Integrated Design

Morphological Semantics: Inspired by “plant root systems,” the fractal flow channel housing symbolizes natural hair growth;

Mechanical Aesthetics Visualization: Sapphire glass windows expose precision atomization components to enhance technological trust.

Step 2-Mechanical Design

1. Atomization Module Innovations

Piezoelectric Ceramic Drive System:

Optimized vibration frequency (15kHz±2%) via ANSYS mechanical dynamics simulation to adapt to 20-500cP viscosity liquids;

Self-Cleaning Blade Mechanism (Patent No. ZL2023XXXXXX):

A 20,000rpm titanium alloy blade driven by a micro-motor eliminates high-viscosity liquid crystallization blockages.

2. Medical-Grade Mechanical Standards

Zero-Residue Delivery System:

3D topology-optimized titanium alloy atomization chamber with ±0.05mm wall thickness precision;

IPX7 Waterproof Structure:

Seamless housing via nano-injection molding, enduring 72-hour salt spray testing without performance degradation.