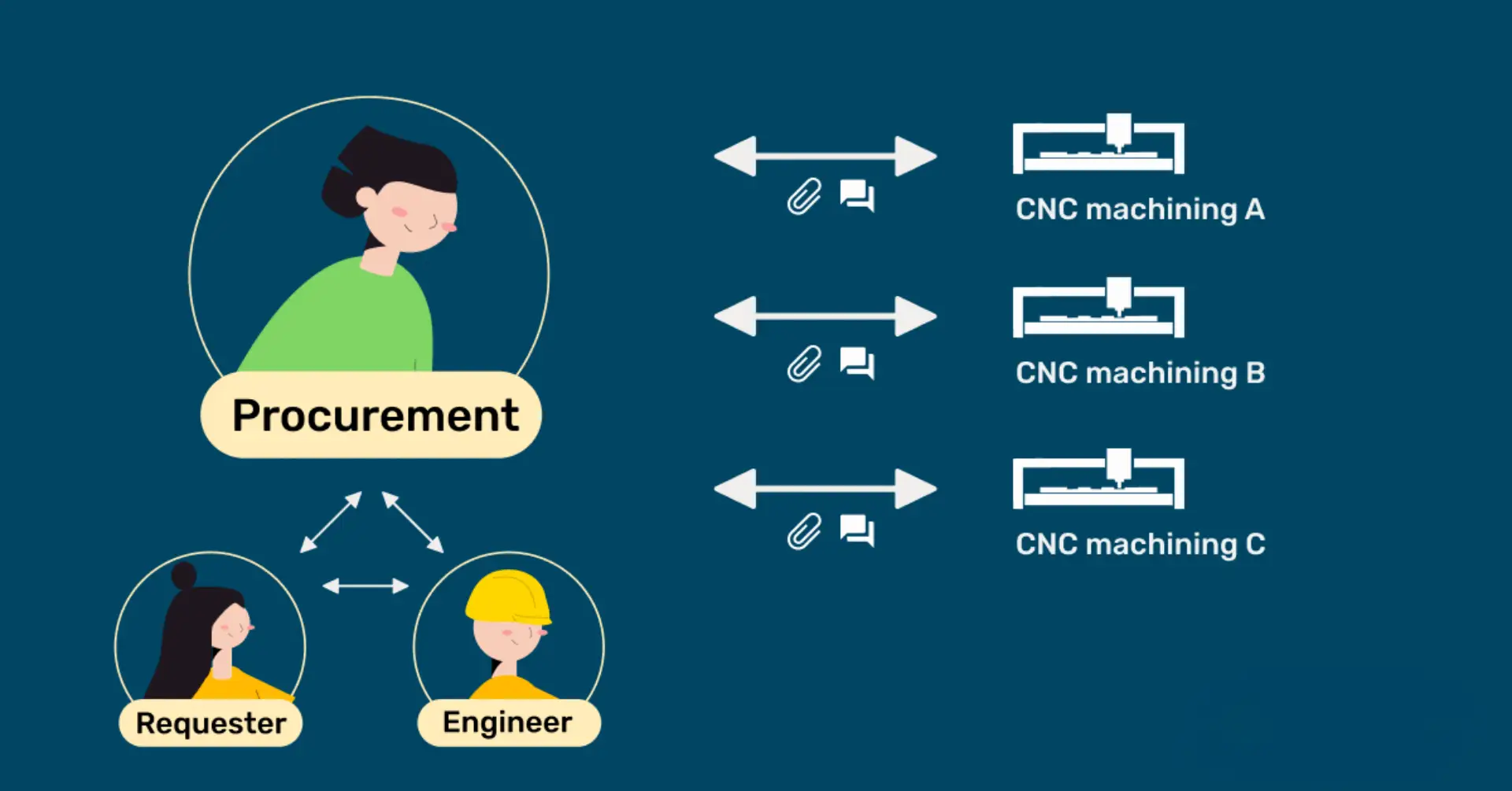

Introduction: Innovating Under Regulatory Scrutiny

Medical electronics design demands a razor-sharp balance between cutting-edge technology and compliance with global standards like FDA 21 CFR Part 820 and EU MDR. McKinsey reports that 40% of medical device delays stem from design-stage compliance gaps—a risk that derails both timelines and budgets.

This article dissects five critical challenges in medical electronics development, illustrated by OPD-Design’s success in securing FDA 510(k) certification for an Infrared Hair Growth Helmet. Download our free Medical Compliance Toolkit to fast-track your product launch.

III. Case Study: FDA 510(k) Certification for Infrared Hair Growth Helmet

Client Profile

- A U.S. biotech startup developing a home-use Low-Level Light Therapy (LLLT) device targeting androgenetic alopecia.

- Goal: Achieve FDA Class II clearance for consumer markets.

Key Challenges

- Technical Compliance:

- FDA required proof of biological safety (650-850nm infrared wavelengths) and clinical efficacy via 6-month human trials.

- EU MDR mandated compliance with IEC 60601-1 electrical safety standards.

- Manufacturing Risks:

- Optical module yield <50%, tripling per-unit costs.

OPD-Design’s Breakthrough Strategy

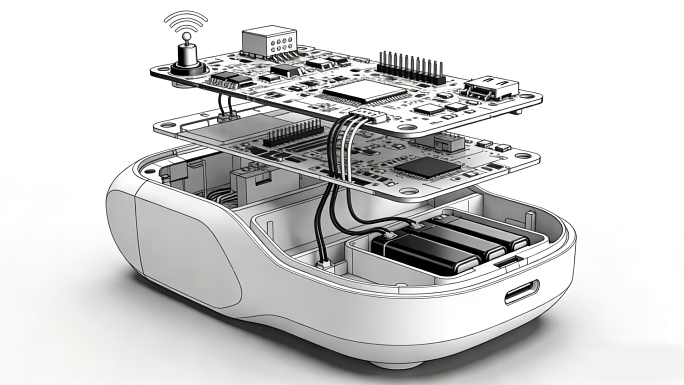

1. Hardware Redesign & Validation

- Optical System Optimization:

- Redesigned multi-channel LED arrays reduced light intensity variance from 22% to <5%.

- Integrated temperature sensors ensured scalp contact surfaces stayed below 41°C (per IEC 60601-2-57).

- EMC Mitigation:

- Deployed common-mode chokes on PCB power layers, cutting radiated emissions below FCC Class B limits.

2. Accelerated Clinical Validation

- Alternative Data Strategy:

- Leveraged existing clinical data from predicate devices (e.g., Capillus®) combined with in-vitro hair follicle assays to reduce human trial requirements.

- Streamlined Testing:

- Partnered with FDA-accredited labs to slash biocompatibility testing from 12 to 6 weeks.

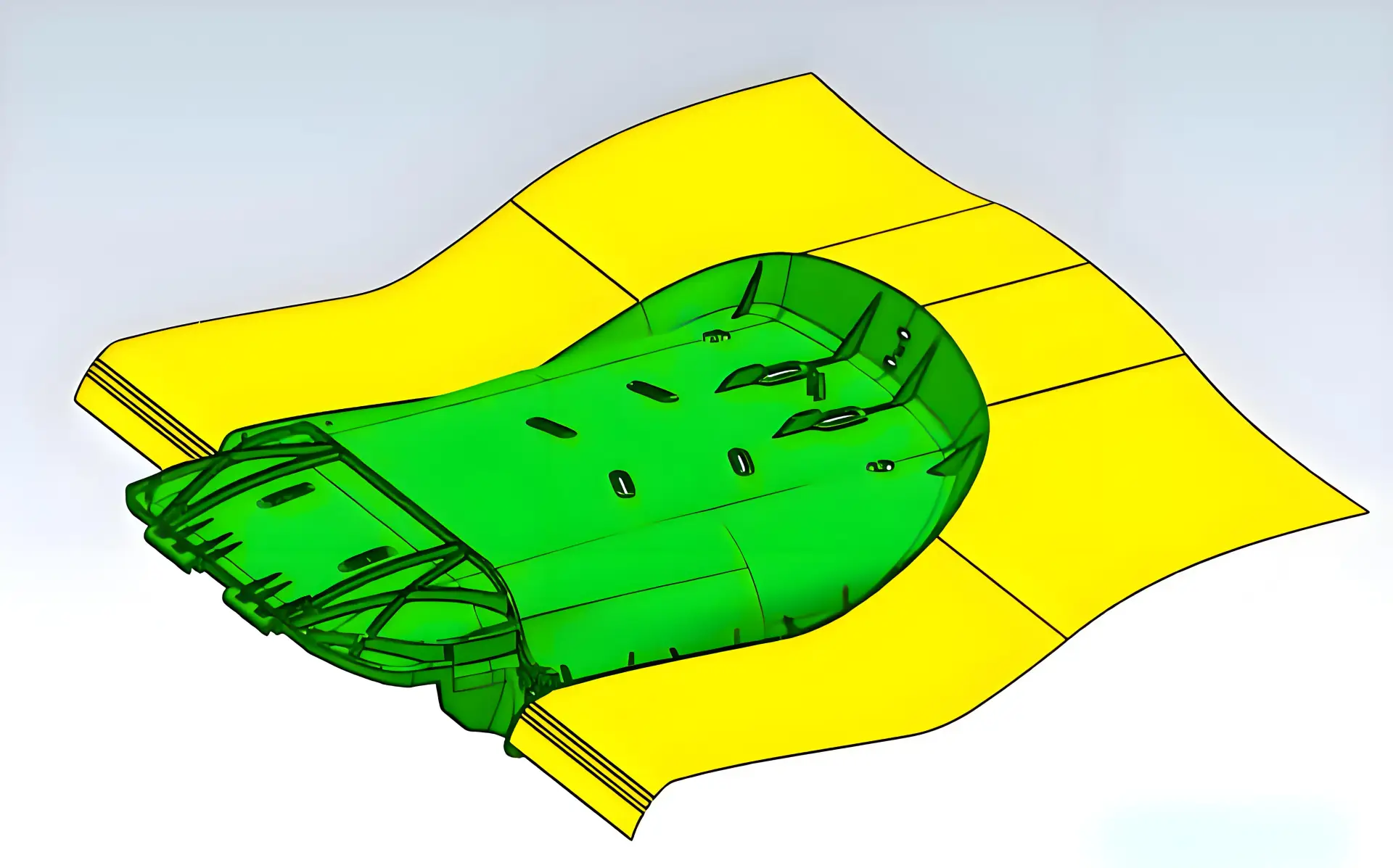

3. Design for Manufacturing (DFM)

- AI-Powered Calibration:

- Developed computer vision systems to auto-adjust LED drivers on production lines, boosting yield to 92%.

- Modular Architecture:

- Decoupled optical cores from housings, enabling hybrid molding/3D printing and cutting tooling costs by 47%.

Results

- FDA 510(k) clearance in 5 months (industry average: 10-14 months).

- Production costs reduced by 35%, with 120,000 units shipped in Year 1.

- Achieved EU MDR certification for Germany, France, and Benelux markets.