Chapter 1: Sparking Innovation – Defining the Toaster Development Vision

The Challenge:

“Create a toaster that masters 7 global bread types, fits compact kitchens, and delivers café-quality results at home – all while consuming 40% less space than traditional models.”

Development Milestones:

- 3 functional prototypes built

- Core achievements:

- Adaptive heating zones: 82% uniformity (target: ≥90%)

- AI bread recognition: 89% accuracy (200+ bread types trained)

Chapter 2: Toaster Development in Action – Prototyping Breakthroughs

Current Technical Hurdles:

| Module | Solution | Development Focus |

|---|---|---|

| Heating System | Quad-Zone Infrared + Convection | Reduce edge from ±8℃ to ±3℃ |

| Lift Mechanism | Magnetic-Assisted Springs | Achieve ±5%consistency |

| Safety Features | Multi-Layer Protection | Integrate arc-fault detection |

Latest Development Data:

- Surface temperature: 68°C under stress (target: ≤55°C)

- Durability: Survived 8,000/15,000 lift cycles

Chapter 3: Development Labs – Rigorous Testing Protocols

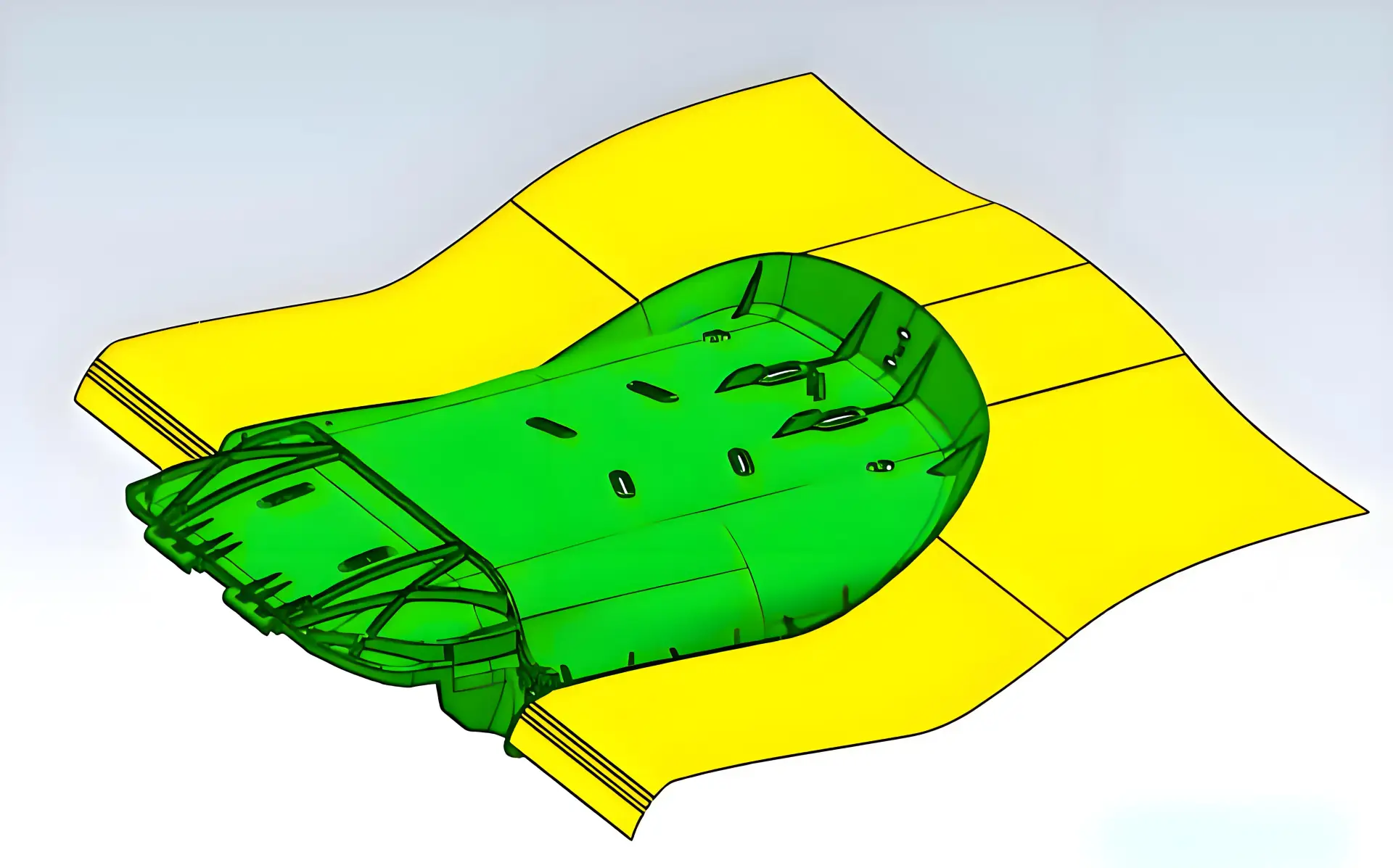

3.1 Thermal Engineering – The Heart of Toaster Development

- Heat Distribution:

- Problem: 25℃ between center and edges

- Solution: Testing hexagonal airflow channels (inspired by beehives)

- Energy Efficiency:

- Current standby power: 0.8W → Targeting 0.5W via dynamic clock gating

3.2 Mechanical Innovation in Toaster Development

- Noise Reduction:

- Baseline: 48dB → Goal: ≤42dB using automotive-grade dampers

- Lifetime Optimization:

- Spring fatigue detected at 8k cycles → Testing titanium alloy alternatives

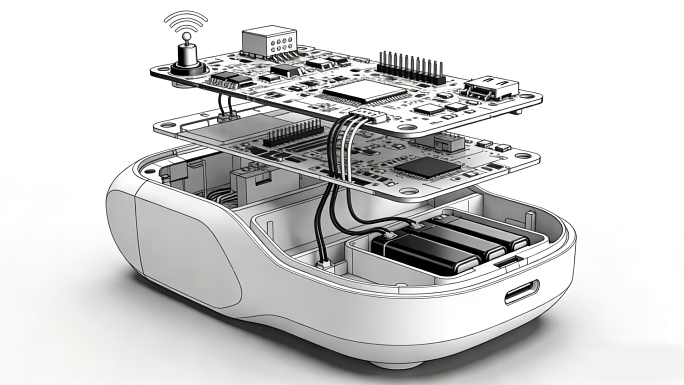

3.3 Smart Tech Integration – The Brain of Toaster Development

- Bread Recognition AI:

- Training dataset expanded to 500 global bread varieties

- Current false-positive rate: 11% → Target: ≤3%

- Voltage Adaptability:

- 110V/220V auto-switching achieved with 93% efficiency

Chapter 4: Toaster Development Crossroads – Balancing Act

Critical Trade-Offs:

- Aesthetics vs. Function:

- Streamlined design caused 15℃ internal temp rise → Testing stealth cooling vents

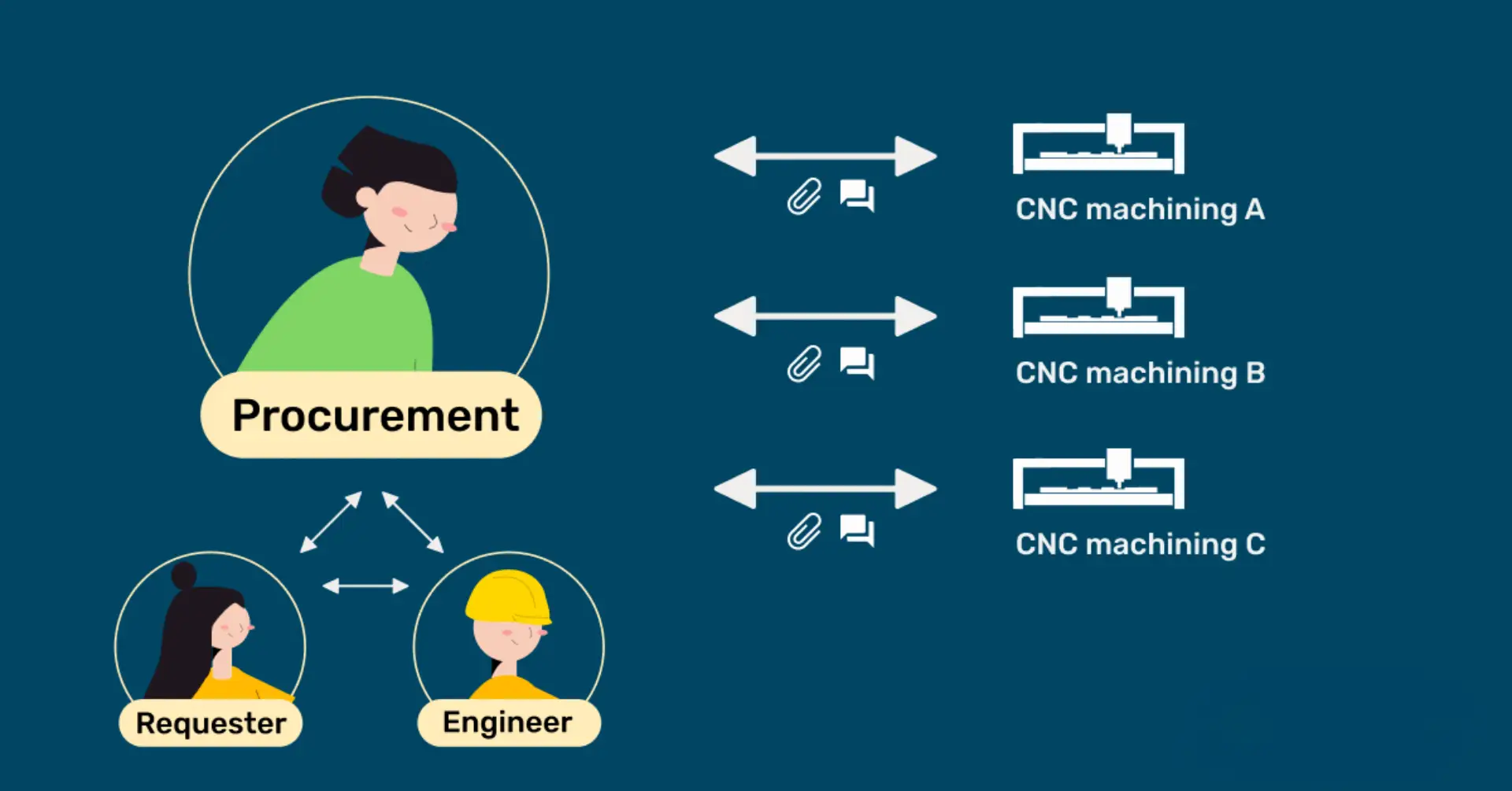

- Cost vs. Performance:

- Heating element options:

- $8.2 Japanese alloy vs. $5.7 nano-coated steel (lifespan TBD)

Chapter 5: Development Metrics – Progress Dashboard

| Metric | Prototype v1 | Current | Target |

|---|---|---|---|

| Browning Consistency | 65% | 82% | ≥90% |

| Preheat Speed | 110s | 75s | ≤60s |

| Error Rate | 38% | 15% | ≤5% |

| Energy Star Rating | – | 0.73 | ≥0.85 |

Chapter 6: The Road Ahead in Toaster Development

Next-Phase Development Goals:

- Global Compliance Testing:

- Voltage fluctuation (85V-264V)

- EU Food Contact Certification (EC 1935/2004)

- User Safety Innovations:

- Child-lock mechanism validation

- Anti-fingerprint coating durability

Epilogue: Redefining Breakfast Through Toaster Development

This toaster’s development journey – 137 tests, 23 iterations, and counting – proves innovation thrives at the intersection of engineering and everyday life. When the latest prototype perfectly toasted sourdough at 3 AM during a 48-hour marathon test, we knew: The kitchen of tomorrow is being forged in today’s labs.