Great ideas are not enough in the quick-moving product industry of today. Businesses must combine creative, engineering, and manufacturing expertise to bring a product to reality. Industrial design companies fit in here. Modern product development is centered on these companies. They turn concepts into useful, attractive, market-ready goods. Industrial design firms are playing more roles than ever, with increasing rivalry and user expectations. They are collaborators from early concept drawings to packaging, testing, and final launch.

1. Translating Ideas into Tangible Concepts

Industrial design firms play a key role in assisting companies transform unrefined ideas into well-organized, understandable product conceptions. Often, customers arrive with a vision but no means to communicate it in technical or visual terms. A product design engineer fits in there. They collaborate to create first sketches and functional outlines with help from the mechanical design engineer and the electronic design team.

Industrial design companies guarantee the product vision matches actual use by means of user scenarios and wireframes. These concept developments enable customers to grasp the possibilities of their ideas and mold them into practical, user-friendly designs. At this point, a successful proposal might hasten development and lower subsequent changes.

2. Ensuring Function Meets Form

While they also have to look and feel appropriate, products ought to function correctly. While industrial design firms are renowned for their stunning designs, it’s about more than simply aesthetics. Every thing they create strikes a balance between form and function. A technically good product, for example, may fail if it is difficult to grasp, overly weighty, or complicated to use.

The product design engineer here collaborates closely with mechanical and electronic design experts. They assess material selections and generate CAD models jointly. A seasoned industrial design firm will investigate how every component influences cost, durability, and usage. The end product ought to be visually beautiful, simple to make, and intuitive to operate.

3. Supporting Prototype Development and Testing

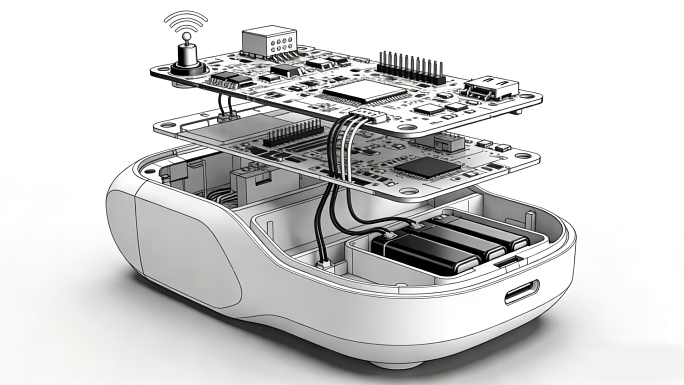

Any product’s life cycle includes a significant turning point called prototype development. Industrial design firms don’t merely leave after handing over designs. They frequently run the physical or digital prototype construction process. Strength, usability, and functionality are then tested on these models.

While designers concentrate on the shell, interface, and experience, a mechanical design engineer and an electronic design expert could create the inner workings of a product. Early faults are revealed by iterative testing. This practical approach enables teams to lower expensive mistakes before manufacturing. According to recent data, approximately 60% of design changes occur after prototyping, indicating its crucial role in refining goods.

4. Integrating Engineering with User Experience (UX)

The top industrial design firms connect engineering accuracy with user-centered mindset. This implies guaranteeing that every technical element benefits the user. A good industrial design company designs with human behaviour in mind using human factors engineering.

The location of buttons on a remote or the curve of a handle, for instance, is not arbitrary. It’s informed by studies on consumer product interaction. Companies guarantee features fit user habits and expectations by cooperating with a mechanical design engineer and a product design engineer. This leads to more seamless interactions and less user mistakes.

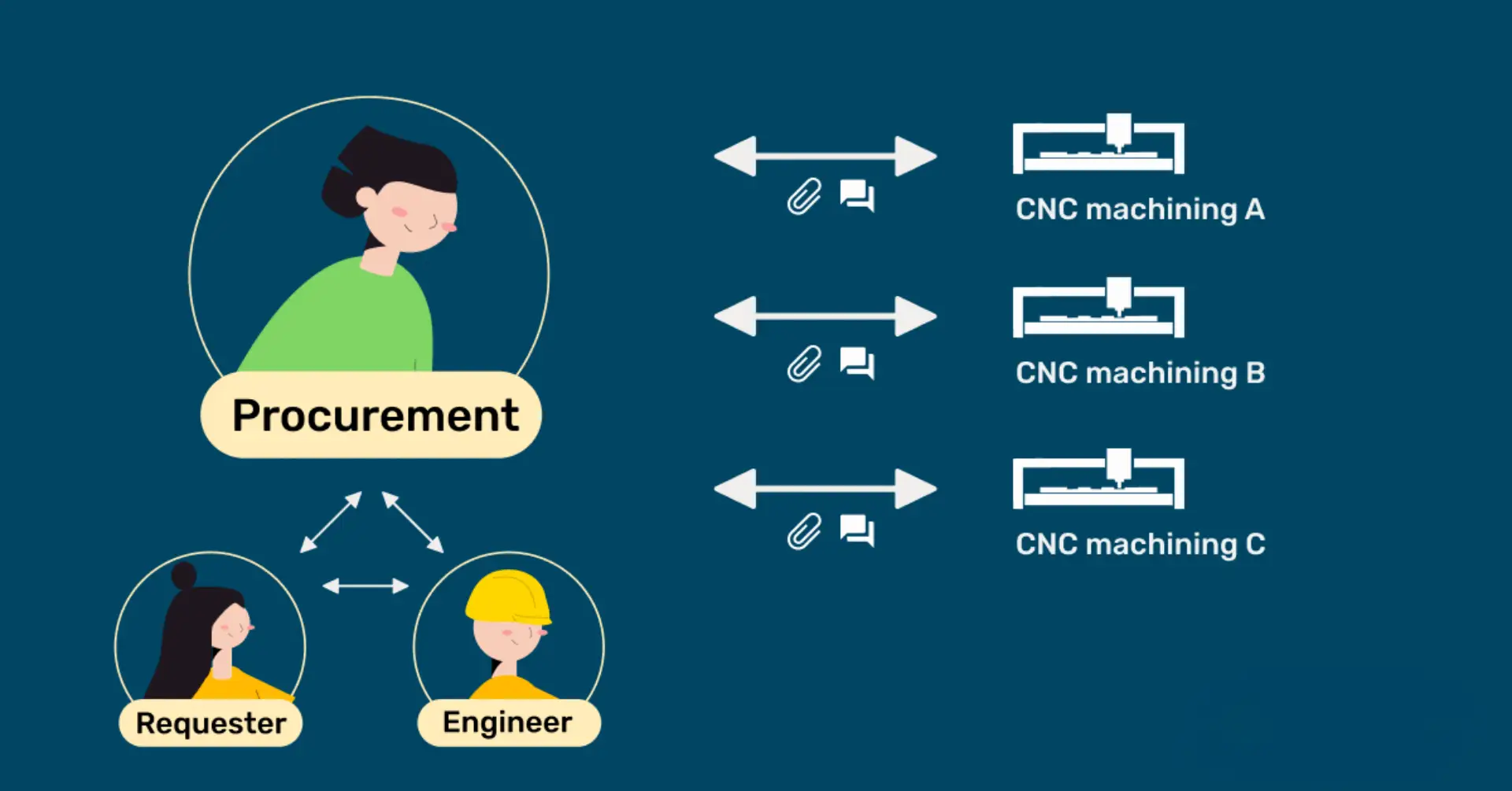

5. Collaborating Across Product Development Teams

One individual does not create any product. To keep projects on track, industrial design companies collaborate closely with manufacturing, engineering, compliance, and marketing departments. While also taking corporate positioning and budget goals into account, they convert imaginative concepts into plans for engineers to construct.

This partnership takes place fast and effectively in Shenzhen, where innovation centres and global supply networks meet. Industrial design firms here are very good at cross-disciplinary planning, vendor cooperation, and time management. When products need several certifications or include sophisticated technologies, their function gets much more important.

6. Designing for Manufacturability

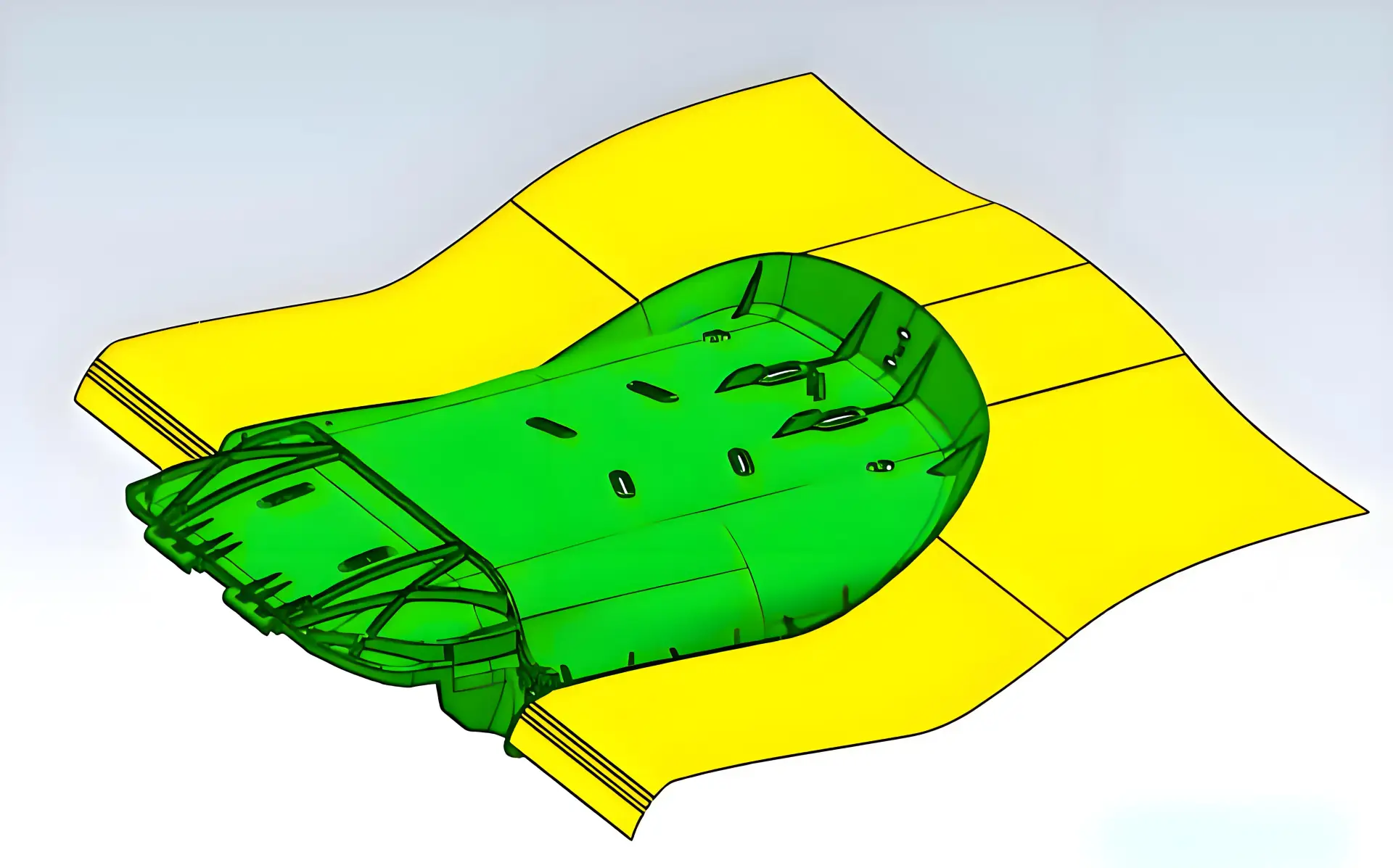

Designing a lovely product is one thing. Designing something that can be made economically and dependably is different. Industrial design companies are professionals in creating for manufacturability. That includes selecting finishes, forms, and materials that complement the manufacturing techniques at hand.

Many companies in China work directly with manufacturers given the country’s robust industrial infrastructure. They create components that improve mold tooling, save waste, and prevent assembly mistakes. Mechanical design engineers are key players in this since they guarantee exact component fit while preserving performance.

Timelines and budgets can be significantly affected by this stage. Industry studies show that bad design-for-manufacturing techniques may raise manufacturing costs by more than 30%. Experienced industrial design firms are therefore great partners in maintaining development efficiency.

7. Managing Compliance and Certifications

Industrial design companies play another important part in negotiating legal standards. From smart appliances to medical tools to electronic devices, the product has to satisfy quality, environmental, and safety criteria. Companies help guarantee designs follow ISO, RoHS, FCC, CE, or other certifying bodies.

Here is where the product design engineer and the electrical design team work with compliance specialists to create items ready for worldwide markets that are safe and legal. Devices having wireless components, for instance, have to fit electromagnetic interference criteria; smart products need to have cybersecurity protections.

Designing with these requirements in mind saves time and avoids rejection during approval stages.

8. Shaping Brand Identity Through Design

Products are also an extension of a brand beyond use and utility. Design language allows industrial design firms to influence a product’s identity. User perception of a product is shaped by elements including color schemes, materials, interface design, and proportions.

Consider famous items like a Tesla key fob or the iPhone. Their shape embodies the promise of innovation, simplicity, and beauty of their brand. Industrial design companies help customers select design components that enhance emotional connection and branding.

Working with talented designers guarantees that every product expresses a brand’s voice even before a user activates it.

9. Accelerating Time to Market

Product development is all about speed. Early-launching companies tend to gain market share and influence industry trends. By means of effective workflow management, industrial design companies help to reduce time to market. Before manufacturing is delayed, they plan sprints, manage conflicting responsibilities, and resolve issues.

Based in tech-savvy places like Shenzhen, these companies use local manufacturing, rapid prototyping, and talented engineers to accelerate from concept to delivery. Bottlenecks are reduced and launch schedules remain reasonable when mechanical design engineers and product design engineers cooperate with the design team.

Working with the correct industrial design agency has significant benefits in speed without compromising quality.

10. Offering Long-Term Product Lifecycle Support

Industrial design companies survive the launch. They frequently back items throughout their lifetime. This covers cost-cutting initiatives, redesigns, and product changes. Companies enable companies to change without beginning from zero when technology develops and consumer demands change.

Companies depend on these businesses to modify goods while maintaining their integrity for compliance renewals or electronic design changes. Long-term participation by a product design engineer and an industrial design firm guarantees stability, cost savings, and brand equity preservation.

Conclusion

Shaping today’s most successful goods is mostly done by industrial design companies. They are the creative and technical link between an idea and a functional, manufacturable, user-approved product. From early drawings to long-term strategy, their work combines form with function, invention with engineering.

From a complicated mechanical tool to a slick technological product, their fingerprints appear on every level. Industrial design companies are not optional for companies trying to stand out, compete internationally, and create goods that consumers really adore; they are quite vital.