IOT Robot

This ecosystemen compassesadvanced technology in three pivotal areas: NLP/GPT, computer vision (CV), and autonomous navigation and walking (SLAM). With many years of technological experience, OPD hassecured more than 200 independent intellectual property rights.

About OPD IOT Robot Industry Solutions

200+

Independent

intellectual

property Rights

7 Years

The big data

platform has been

operational

3 Billion

Have been

provided to users

Technical advantages

of OPD AI robot

(Natural Language Processing)

The robot’s brain starts by decipher-ing human languageand thinkingpatterns, creatively decoding thesepatterns,and summarizing the prin-ciples behind human thoughts,emotions,and behaviorsinto aset ofreplicableand imitable programs.

(Imagese manticunder standingand object grasping)

(Localization and Mapping)

The robot’s feet commence fromanun specified positioninan unfamiliar environment. As theymove, the robot detectsits own locationand orientation bycontinuously observing environmental features likecornersand pillars. By leveraging these observations, it in crementally construct samap based onits detected position. This proces senables the robot to achieve thegoal of simultaneous localizationand mapping (SLAM).

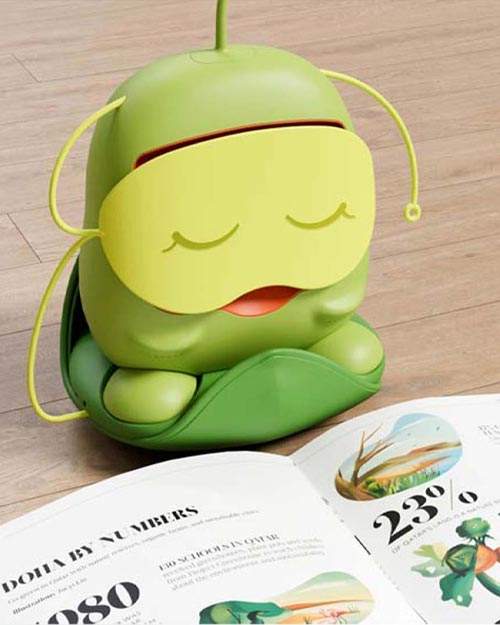

Featured Projects

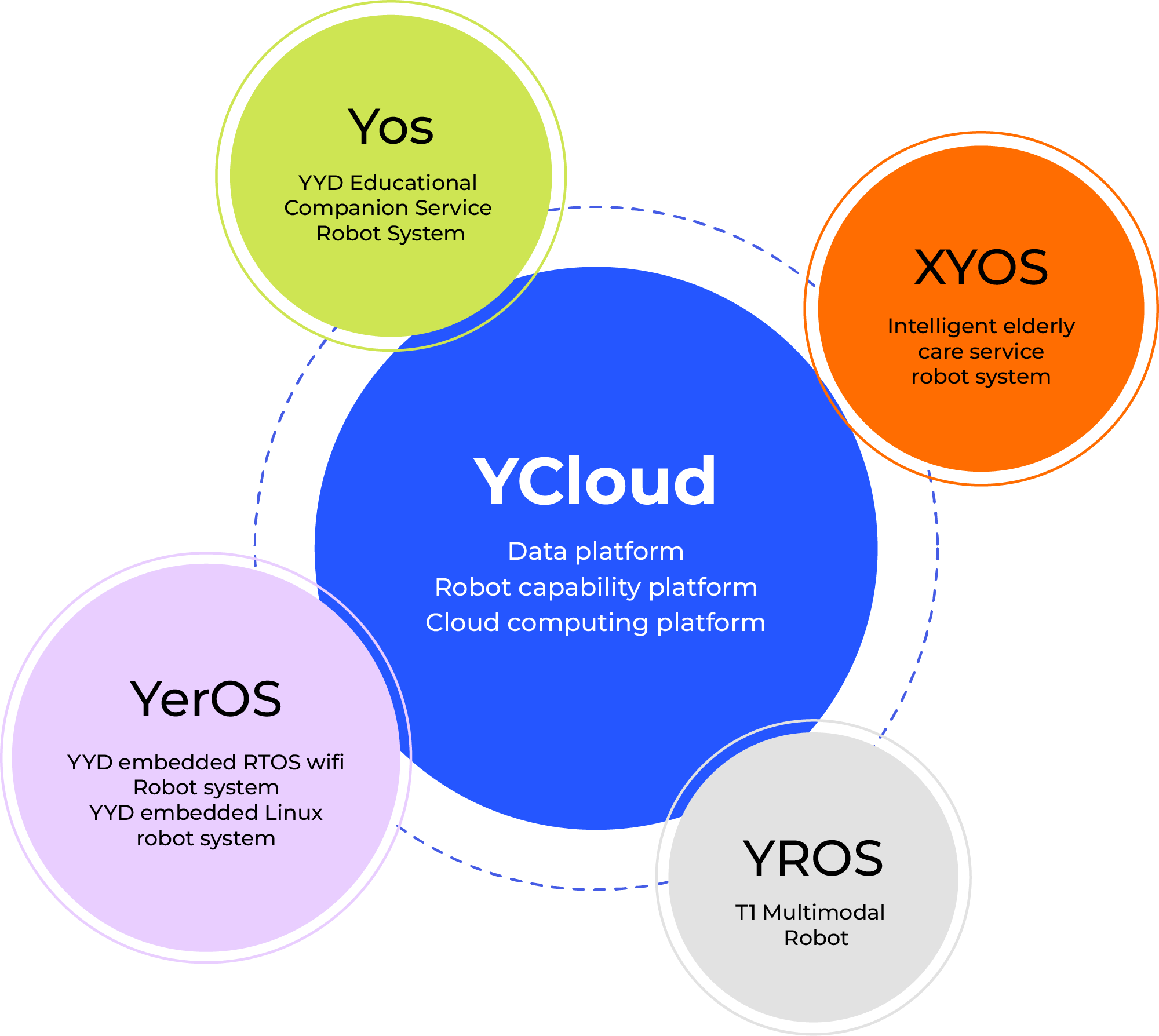

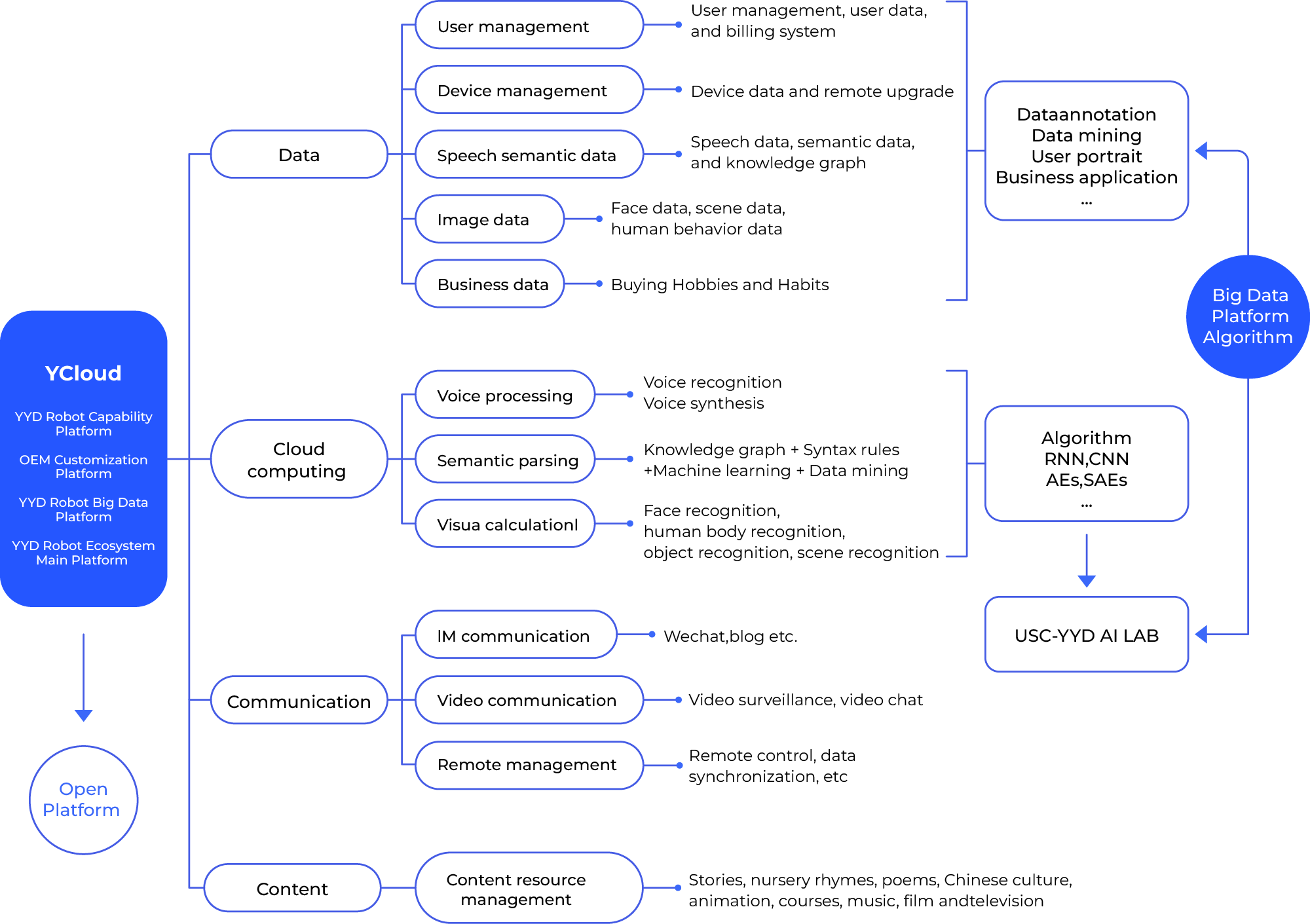

Technical architecture of OPD IOT robot

"Five-in-one"

Ecosystem Platform

Cloud Architecture

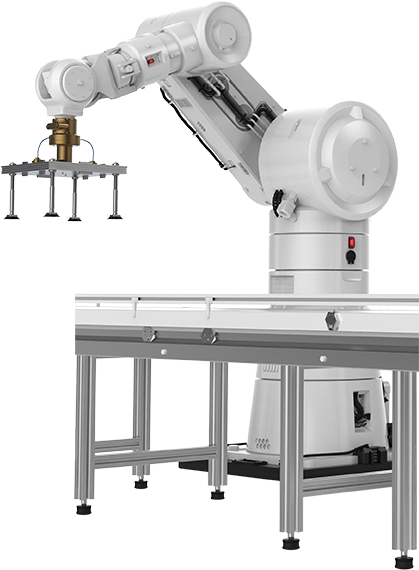

Production Capacity

The foundation of our DFM is our manufacturing capabilities. We have significant production resources, so wedesign from a production perspective. Our industry-leading intelligent manufacturing equipment, coupled with ahighly experienced production management team, enables us to deliver comprehensive production solutions tai.lored to innovative products.

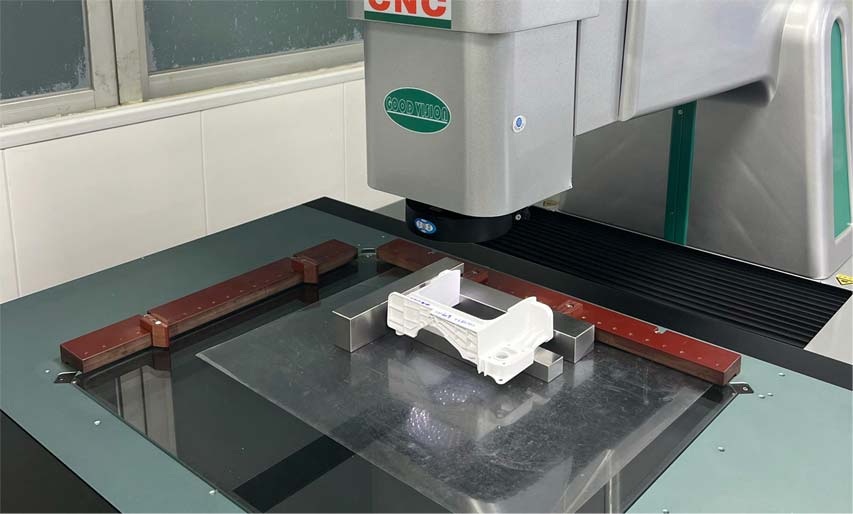

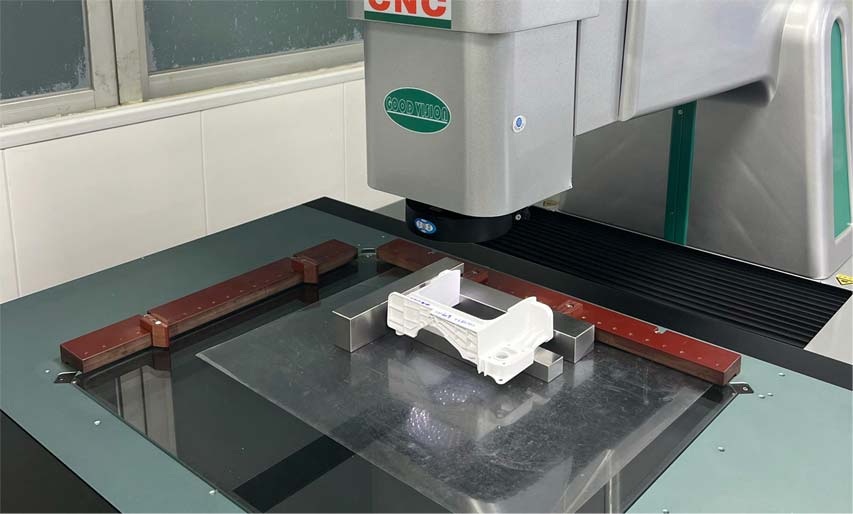

Prototype

Our prototype center boasts advanced equipment, including 3D printers, CNC machines, and vacuum molding machines. With more than 20 seasoned professionals on our team, we specialize in creating plastic prototypes, metal prototypes, and various other types. Leveraging our exquisite craftsmanship and efficient services, we deliver precise prototype solutions to expedite product development and market introduction

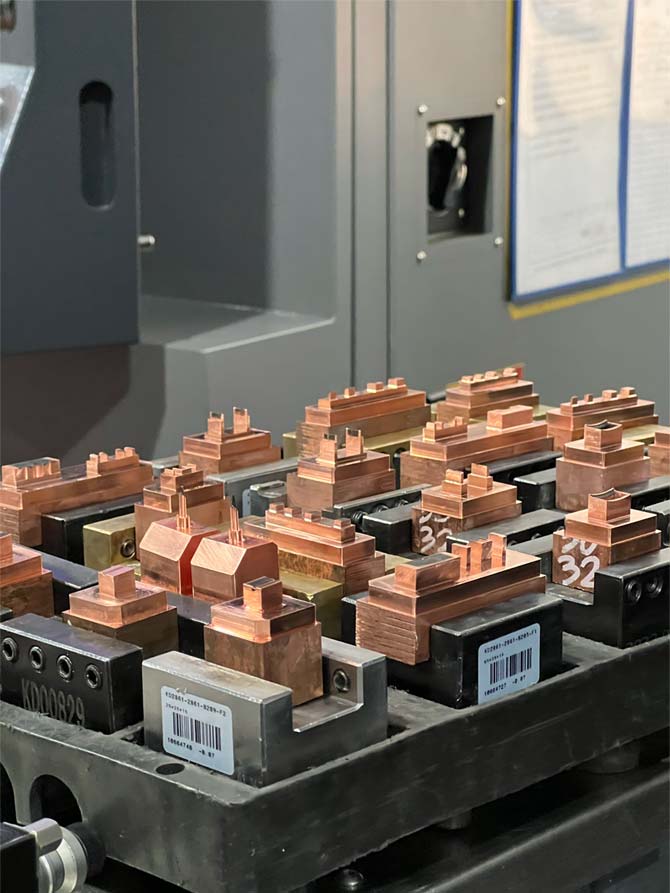

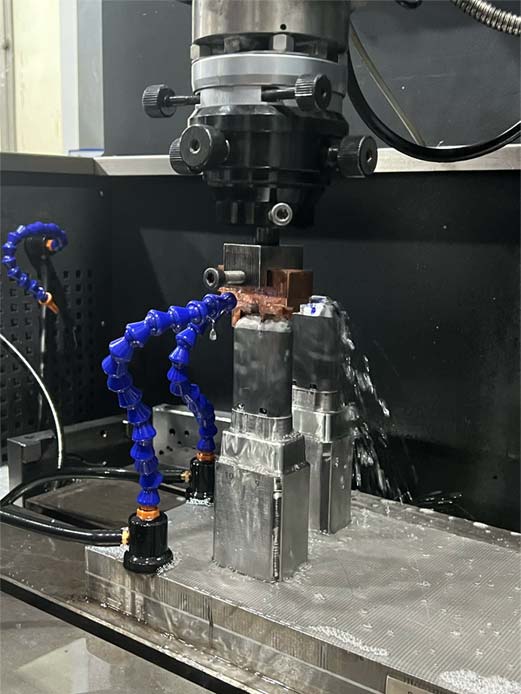

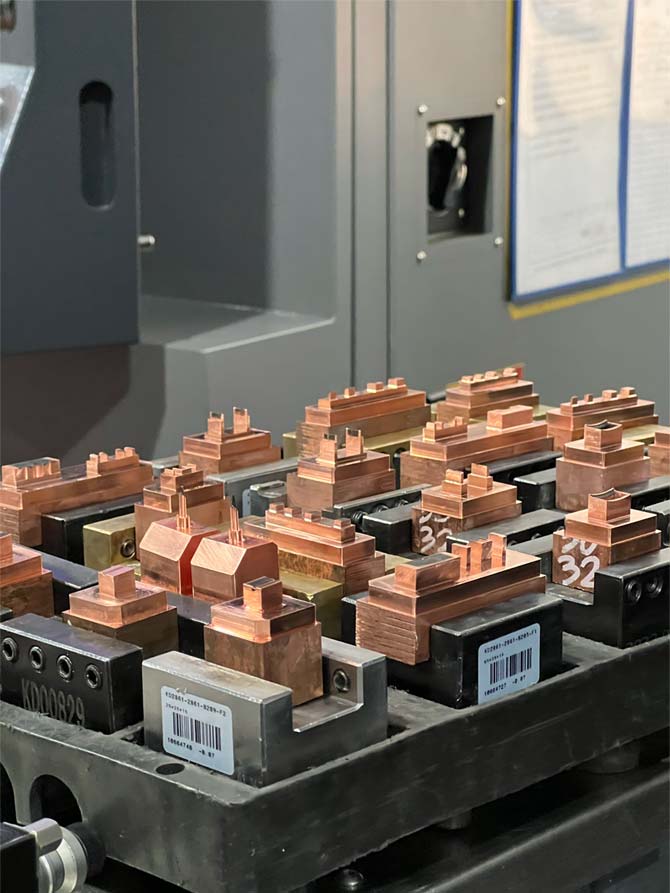

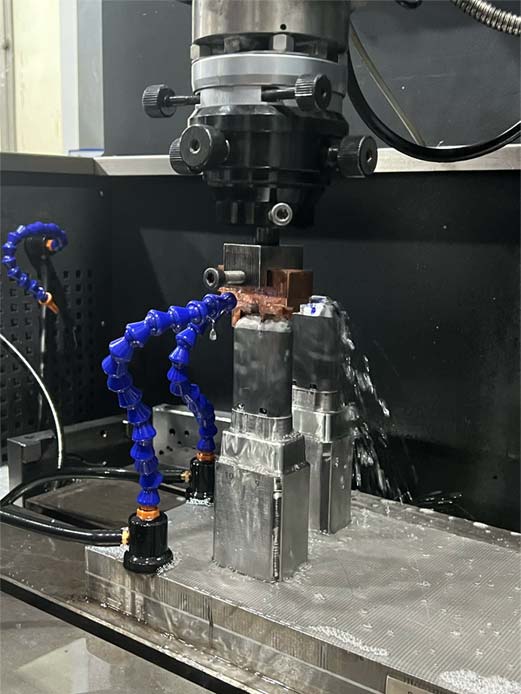

Mould

Mold workshop is equipped with state-of-the-art processing equipment, including high-precision CNC machine tools and EDM machines. Our professional team consists of over 40 highly skilled members, specializing in the manufacture of injection molds and die-casting molds. These molds are extensively utilized in various sectors such as automotive, electronics, and home appliances.

Main Equipment:

- CNC Spark Machines (SODICK, etc.)

- CNC Slow Wire (SODICK)

- CNC High-Speed CNC (DMG, MAKINO)

Injection

Molding

Our injection molding workshop is equipped with numerous advanced injection molding machines of various specifications, capable of accommodating a wide range of product sizes. The workshop features professional mold installation and debugging equipment, alongside an automated material conveying system. Our dedicated technical team, comprising 60 skilled professionals, rigorously oversees the production process to ensure the highest quality of each injection molding product.

Key Features:

1.Injection Molding Equipment:

- 47 injection molding machines

2.Distribution of Injection Molding Machines:

- One 1250-ton injection molding machine

- One 400-ton injection molding machine

- Twenty 160-ton to 250-ton injection molding machines

3.Injection Accuracy:

- Injection position accuracy up to 0.1MM

- Product size accuracy controlled within 0.01MM

- Advanced power system boosts injection speeds to 130-140MM/S, enabling the injection of thin-walled plastic products (0.2~0.5mm)

Spraying

The spraying workshop is designed as a 10,000-level dust-free environment. Our main production process utilizes a fully automated two-coat and two-bake spraying technique. The automatic line is equipped with high-quality spray gun equipment and high-energy UV light curing equipment.

Key Features:

1.Spraying Equipment:

- One two-coat and two-bake automatic spraying line

- Two robot large-piece spraying lines

- One printing line

- Twenty pad printing machines

2.Production Capacity:

- Smart wearable spraying: 5 million pieces per month

- Robot small and medium-sized part spraying: 1 million pieces per month

- Robot large-piece spraying: 30,000 pieces per month

- Printing: 4 million pieces per month

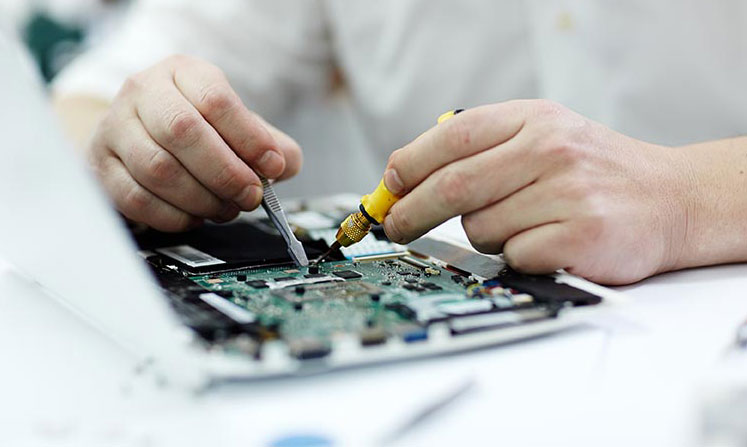

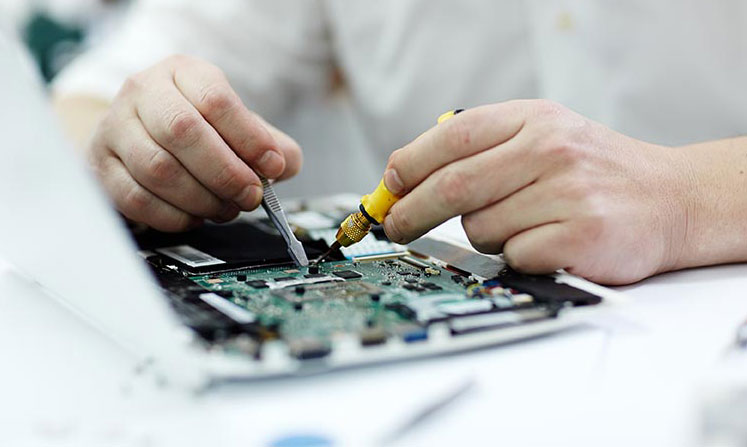

Assembly

Our company currently operates two 100,000-level dust-free assembly workshops and seven bidirectional assembly lines, all housed within a newly constructed four-story supporting factory building, totaling 16,000m². This infrastructure is designed to meet the increasing demand for orders.

Key Features:

1.Assembly Department

- Four assembly lines

- Main production includes customized machines, Y10 series, Y20 series

- One Y50 series customized line

- Three bidirectional assembly lines for other models

2.Assembly Department

- Primarily a dedicated production line for the 150CM large machine series

- Two bidirectional assembly lines for other models

3.Assembly Capacity:

- Assembly Department 1: 250,000 finished units per month

- Assembly Department 2: 130,000 finished units per month

Testing

Each robot product we manufacture undergoes rigorous testing to ensure reliable product quality. Our testing laboratory is equipped with a comprehensive range of advanced equipment to perform various assessments.

Testing Equipment:

- Projector

- Colorimeter

- Halogen Lamp Moisture Meter

- Impact Tester

- Tensile/Bending/Strength Tester

- Vicat Thermal Deformation Tester

- RCA Paper Tape Tester

- Waterproof Tester

- Friction Tester

- Flame Flow Rate Velocity Apparatus

- Horizontal and Vertical Combustion Tester

- Hardness Tester

Our prototype center boasts advanced equipment, including 3D printers, CNC machines, and vacuum molding machines. With more than 20 seasoned professionals on our team, we specialize in creating plastic prototypes, metal prototypes, and various other types. Leveraging our exquisite craftsmanship and efficient services, we deliver precise prototype solutions to expedite product development and market introduction

Mold workshop is equipped with state-of-the-art processing equipment, including high-precision CNC machine tools and EDM machines. Our professional team consists of over 40 highly skilled members, specializing in the manufacture of injection molds and die-casting molds. These molds are extensively utilized in various sectors such as automotive, electronics, and home appliances.

Main Equipment:

- CNC Spark Machines (SODICK, etc.)

- CNC Slow Wire (SODICK)

- CNC High-Speed CNC (DMG, MAKINO)

Our injection molding workshop is equipped with numerous advanced injection molding machines of various specifications, capable of accommodating a wide range of product sizes. The workshop features professional mold installation and debugging equipment, alongside an automated material conveying system. Our dedicated technical team, comprising 60 skilled professionals, rigorously oversees the production process to ensure the highest quality of each injection molding product.

Key Features:

1.Injection Molding Equipment:

- 47 injection molding machines

2.Distribution of Injection Molding Machines:

- One 1250-ton injection molding machine

- One 400-ton injection molding machine

- Twenty 160-ton to 250-ton injection molding machines

3.Injection Accuracy:

- Injection position accuracy up to 0.1MM

- Product size accuracy controlled within 0.01MM

- Advanced power system boosts injection speeds to 130-140MM/S, enabling the injection of thin-walled plastic products (0.2~0.5mm)

The spraying workshop is designed as a 10,000-level dust-free environment. Our main production process utilizes a fully automated two-coat and two-bake spraying technique. The automatic line is equipped with high-quality spray gun equipment and high-energy UV light curing equipment.

Key Features:

1.Spraying Equipment:

- One two-coat and two-bake automatic spraying line

- Two robot large-piece spraying lines

- One printing line

- Twenty pad printing machines

2.Production Capacity:

- Smart wearable spraying: 5 million pieces per month

- Robot small and medium-sized part spraying: 1 million pieces per month

- Robot large-piece spraying: 30,000 pieces per month

- Printing: 4 million pieces per month

Our company currently operates two 100,000-level dust-free assembly workshops and seven bidirectional assembly lines, all housed within a newly constructed four-story supporting factory building, totaling 16,000m². This infrastructure is designed to meet the increasing demand for orders.

Key Features:

1.Assembly Department

- Four assembly lines

- Main production includes customized machines, Y10 series, Y20 series

- One Y50 series customized line

- Three bidirectional assembly lines for other models

2.Assembly Department

- Primarily a dedicated production line for the 150CM large machine series

- Two bidirectional assembly lines for other models

3.Assembly Capacity:

- Assembly Department 1: 250,000 finished units per month

- Assembly Department 2: 130,000 finished units per month

Each robot product we manufacture undergoes rigorous testing to ensure reliable product quality. Our testing laboratory is equipped with a comprehensive range of advanced equipment to perform various assessments.

Testing Equipment:

- Projector

- Colorimeter

- Halogen Lamp Moisture Meter

- Impact Tester

- Tensile/Bending/Strength Tester

- Vicat Thermal Deformation Tester

- RCA Paper Tape Tester

- Waterproof Tester

- Friction Tester

- Flame Flow Rate Velocity Apparatus

- Horizontal and Vertical Combustion Tester

- Hardness Tester