Transforming Cost Centers into Value Architects

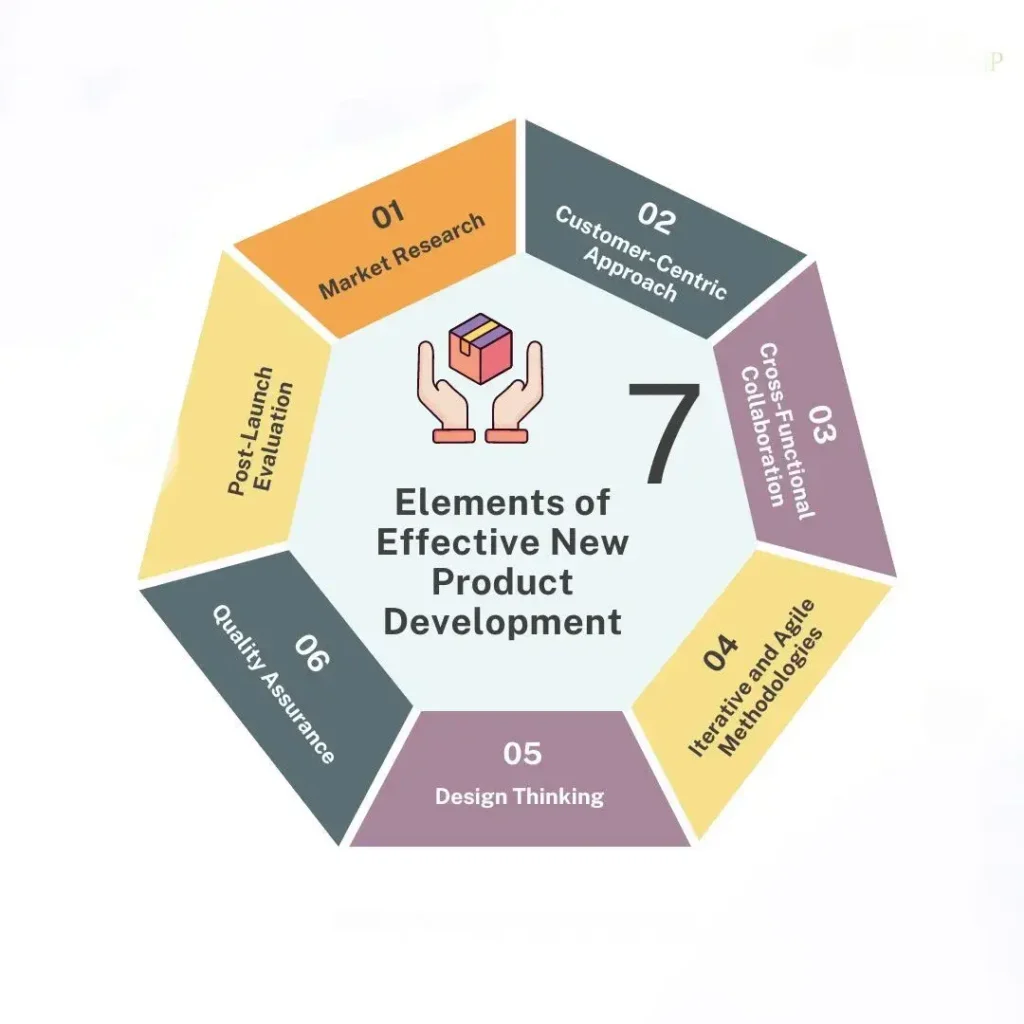

In today’s hypercompetitive markets, isolating procurement until design finalization risks locking in 70% of product costs prematurely while forfeiting optimization opportunities4. Leading enterprises now leverage procurement collaboration—a systemic approach integrating R&D, manufacturing, and supplier capabilities—to slash time-to-market by 30% and costs by 15%310. Unlike broad “innovation” frameworks, this model specifically targets new product development (NPD) efficiency through cross-functional synergy.

1. Core Principles: Integrating Procurement into NPD DNA

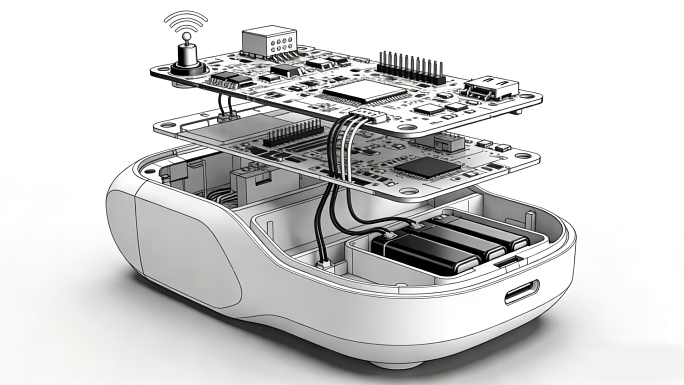

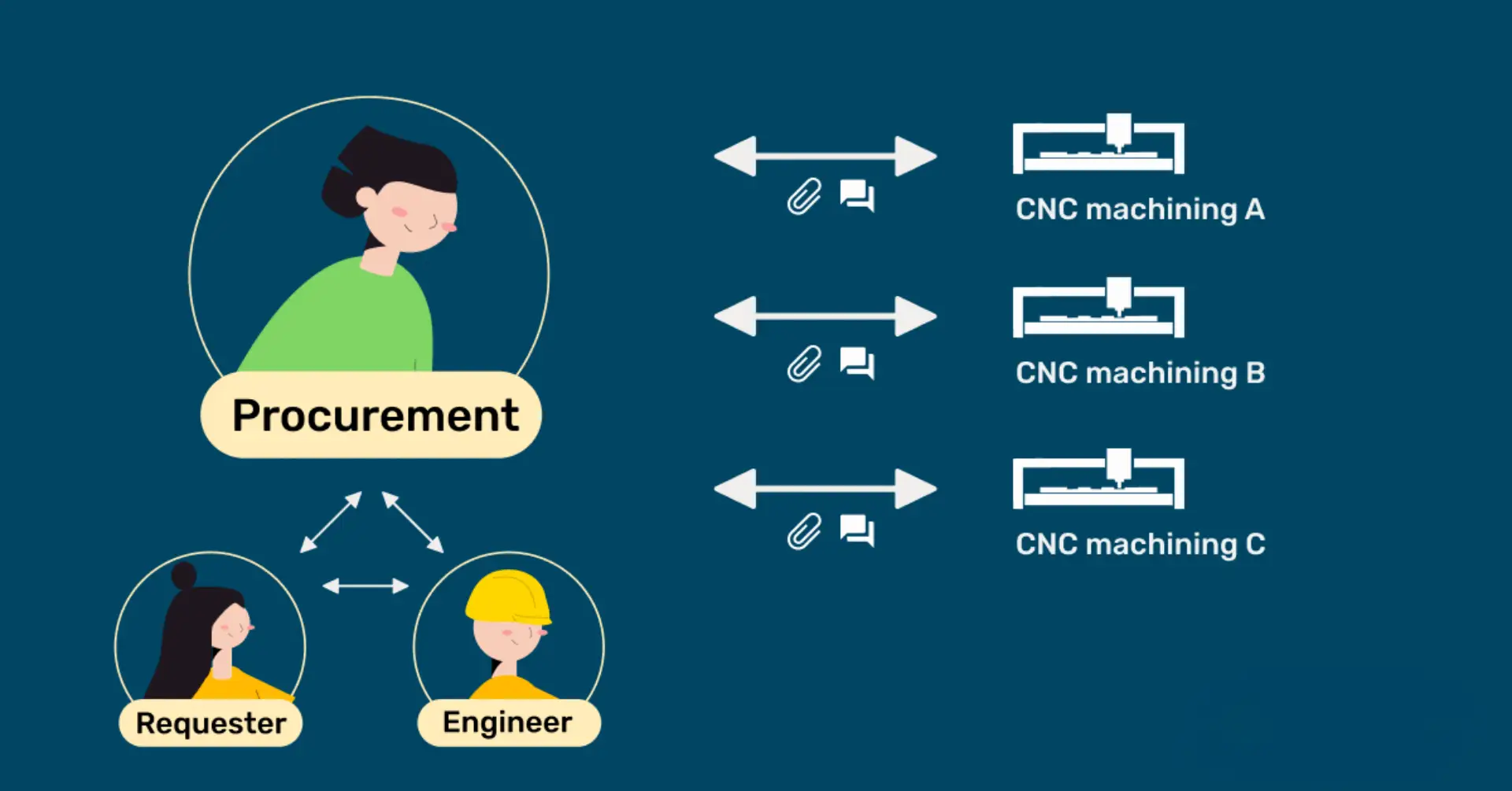

Procurement collaboration dismantles silos to embed supply chain intelligence early in NPD:

- Cross-Functional Nesting

Procurement teams join R&D at the concept stage, validating feasibility. *Example: Toyota’s procurement engineers co-develop production lines during design, cutting launch cycles by 50%. - Supplier-Led Design Optimization

Early partnerships transform vendors into co-creators. *Siemens saved $2.1M on turbine components through supplier-led additive manufacturing redesign. - Lifecycle Cost Governance

Should-cost modeling dissects material economics. Bosch reduced component weight by 20% via joint value engineering with suppliers.

The Paradigm Shift: Procurement evolves from negotiator to NPD value architect, converting fragmented data into actionable design intelligence.

2. Three Levers for NPD Excellence

2.1 Data-Driven Design Acceleration

- Supplier Intelligence Systems

Dynamic databases map vendor capabilities and risks. IBM’s AI platform reduced material shortages by 40% by predicting disruptions 12 weeks ahead. - Real-Time Cost Integration

Embedded market analytics enable rapid adjustments. *Caterpillar averted 11% cost overruns via API-driven steel price monitoring.

2.2 Accelerating Time-to-Market

| NPD Phase | Procurement Collaboration Tool | Outcome |

|---|---|---|

| Design | Early supplier involvement (ESI) | 18–24% shorter development cycles9 |

| Prototyping | Dedicated NPI supply channels | 95% first-sample success rate |

| Mass Production | Blanket PO + tier-2 supplier access | IC procurement: 18→8 weeks |

*Airbus compressed A350 part validation from 8 weeks to 72 hours via digital twin co-simulation.

2.3 Risk Mitigation in NPD

- Resilience Engineering

Multi-tier monitoring (geopolitical/financial). *Samsung averted $380M losses during chip shortages via blockchain-enabled supplier mapping. - Compliance-by-Design

Automated regulatory checks. *Unilever reduced certification delays by 70% across 50+ markets.

3. Digital Enablers for Scalable Collaboration

Technology bridges design-supply gaps:

- Digital Thread

Real-time CAD/PLM synchronization cuts design iterations by 45% (Boeing case). - AI Orchestration

Predictive analytics optimize material selection. GE’s material AI trimmed jet engine weight by 12%. - Blockchain Trust

Tamper-proof certifications slash dispute resolution from 30 days to 48 hours (Maersk-IBM TradeLens).

Key Insight: Value lies in unified demand-design-supply data flows. Nestlé’s supplier portal reduced ingredient qualification cycles by 65%.

4. Implementation Roadmap for NPD Teams

1: Process Integration (0–6 Months)

- Embed procurement checkpoints at NPI gates (e.g., DFM/DFA reviews)

- Include procurement in design FMEAs with supplier capability data

2: Capability Transformation (6–12 Months)

- Train technical procurement engineers in CAD basics, cost modeling, and agile contracts

- Create innovation incentives: Philips’ joint IP agreements accelerated med-device co-development

3: Ecosystem Synergy (12–24 Months)

- Build open platforms: Siemens Xcelerator APIs connect partners across 18 countries

- Redefine KPIs: Shift from “cost savings” to “% revenue from co-developed products”

5. Strategic Impact: Quantifying NPD Success

Procurement collaboration drives measurable NPD outcomes:

- Cost Control

Contributes 40%+ cost avoidance in target costing (Volvo’s modular EV platform). - Speed to Market

ESI reduces development iterations by 60% (*Meta-analysis of 51 studies*). - Sustainability Compliance

Carbon footprint tracking enables 1.2M-ton/year emission reductions (Apple’s clean-energy partnerships).

Industry Imperative: When procurement collaboration becomes organizational DNA, NPD evolves from a relay race into a symphony of synchronized capabilities. Tesla co-debugged Cybertruck lines during stress-testing—launching 14 months ahead of competitors.