Plastic material selection is the cornerstone of successful product development, influencing everything from performance to profitability. With thousands of polymers available, designers and engineers must navigate technical, aesthetic, and economic factors to make the best choice. This guide unpacks proven strategies for plastic material selection, empowering teams to avoid costly mistakes and innovate confidently.

1. Key Factors in Plastic Material Selection

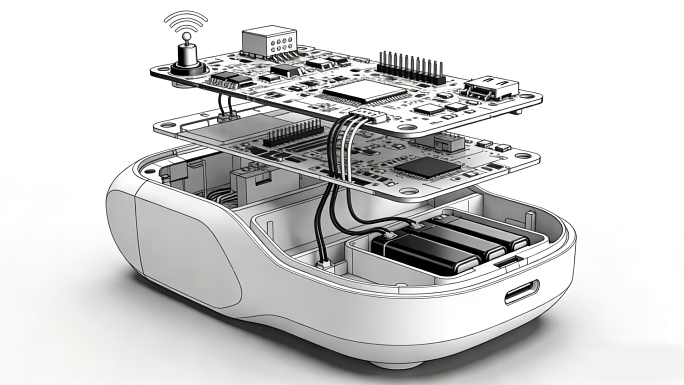

1.1 Functional Requirements: The Foundation of Material Choice

- Mechanical Needs:

- Impact Resistance: ABS for consumer electronics (e.g., drone housings).

- Flexural Strength: 30% glass-filled nylon (PA6-GF30) for automotive brackets.

- Fatigue Resistance: PP for snap-fit closures (e.g., medical device casings).

- Environmental Demands:

- Outdoor Use: UV-stabilized PC/ASA blends for garden tools (e.g., 10-year weatherability).

- Chemical Exposure: PVDF for laboratory equipment handling aggressive solvents.

1.2 Aesthetic Alignment: Where Plastic Material Selection Meets Design Vision

- Surface Finish Options:

- High-Gloss: Electroplating-grade ABS (Ra < 0.1 μm).

- Soft-Touch: TPE-overmolded PC for premium feel.

- Transparency Levels:

- Optical Clarity: COP (Cyclo Olefin Polymer) for medical cuvettes (92% light transmission).

- Light Diffusion: PMMA with micro-textured surfaces for LED panels.

1.3 Manufacturing-Driven

| Process | Top Material Picks | Critical Compatibility Factors |

|---|---|---|

| Injection Molding | ABS, PP, POM | Melt flow index (MFI) > 15 g/10min |

| Extrusion | HDPE, PVC | High melt strength, minimal sag |

| Vacuum Forming | HIPS, PETG | Uniform wall thickness distribution |

1.4 Regulatory Compliance in Material Selection

- Food Safety: FDA-compliant PET for water bottles.

- Flame Ratings: UL94 V-0 PC/ABS for EV battery components.

- Medical Standards: ISO 10993-certified PEEK for implants.

2. Cost-Effective Material Selection Strategies

2.1 Smart Material Substitutions

- Case Study: Replacing PC with talc-filled PP (20% talc) reduced automotive console costs by 35% while maintaining stiffness.

- Pro Tip: Use calcium carbonate-filled HDPE as a cost-effective alternative to unfilled grades for non-structural parts.

2.2 Design for Efficient Material Use

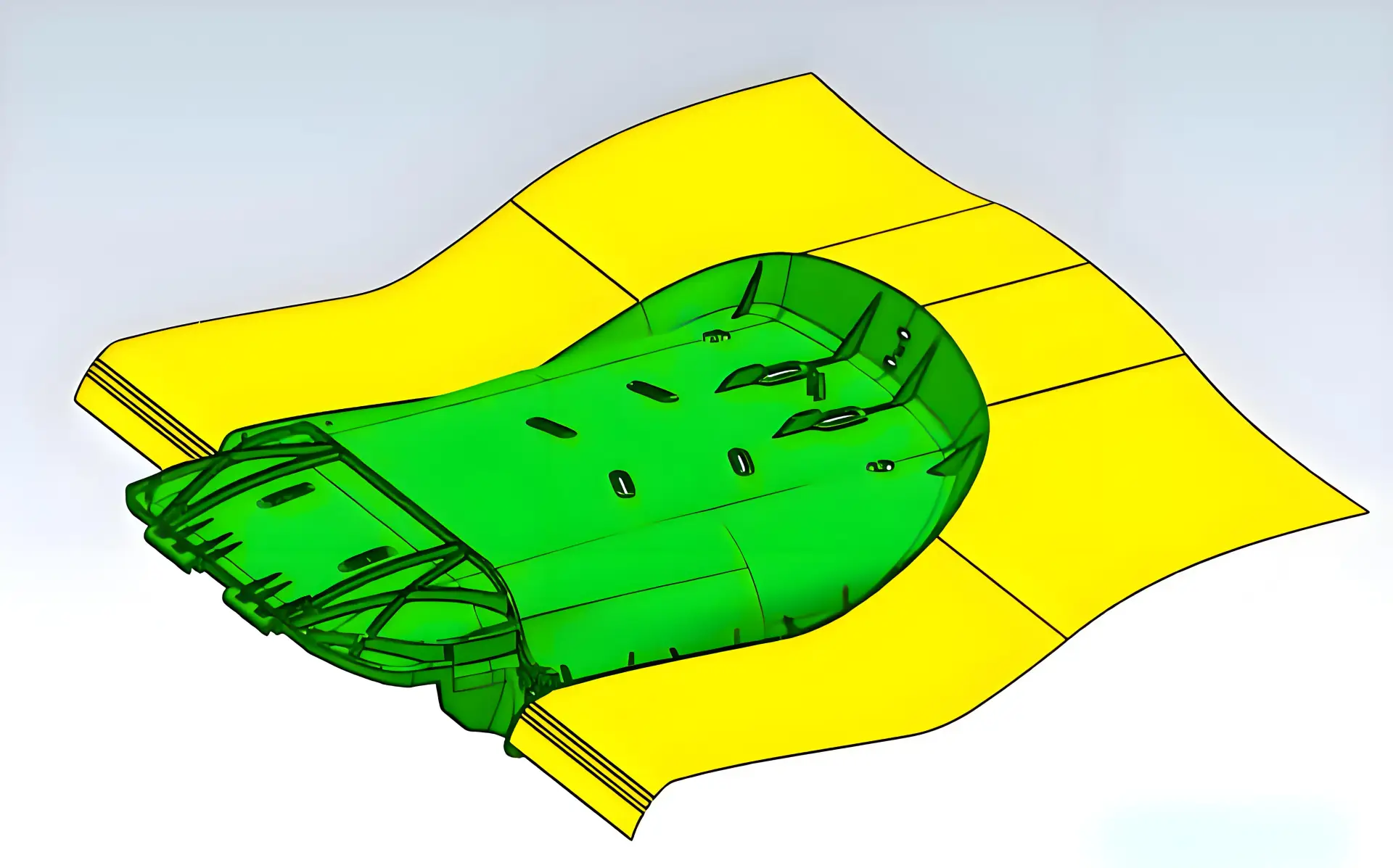

- Wall Thickness Optimization:

- Thin-Wall Design: 0.8–1.2 mm for packaging (requires high-flow materials like LCP).

- Ribbed Structures: 1.5 mm base + 0.6 mm ribs for load-bearing parts.

- Simulation Tools:

- Autodesk Moldflow Analysis: Predict sink marks and warpage during plastic material selection.

2.3 Sustainable Material Selection

- Post-Consumer Recyclates: 50% rPET in furniture components.

- Bio-Based Polymers: PA11 from castor oil for eco-conscious footwear.

- Closed-Loop Systems: Regrind ABS with <5% property loss for non-critical parts.

3. Advanced Considerations in Modern Material Selection

3.1 High-Performance Material Trends

- Conductive Polymers:

- Carbon nanotube-filled PPS for EMI shielding in 5G devices.

- Self-Lubricating Grades:

- PTFE-impregnated POM for gear applications (50% friction reduction).

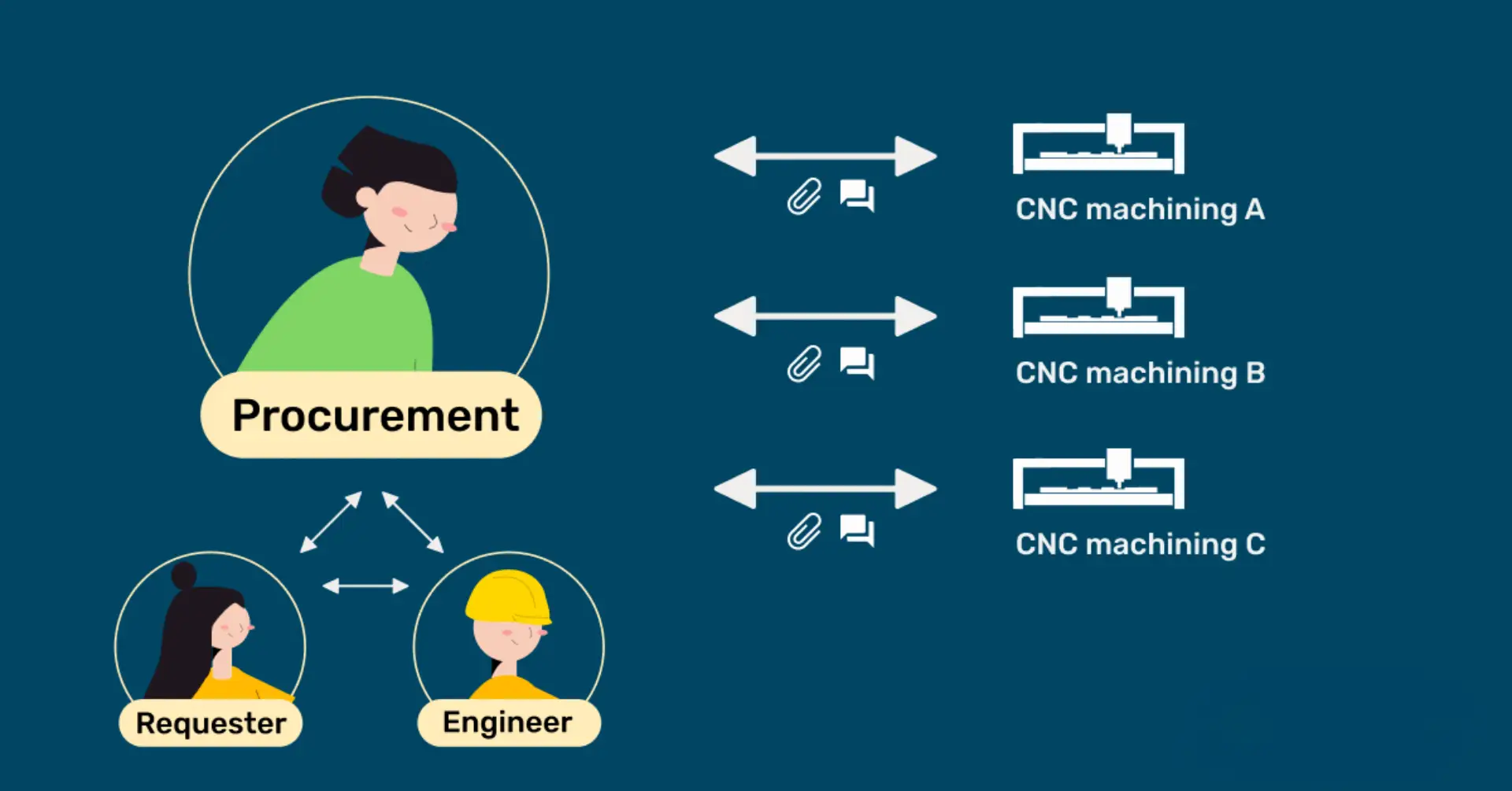

3.2 Digital Tools Revolutionizing Material Selection

- AI-Powered Databases:

- Matmatch: Compare 100,000+ materials using multi-criteria filters.

- 3D Printing Compatibility:

- ULTEM™ 9085 for FDM aerospace components with FST certification.

4. Essential Tools for Effective Plastic Material Selection

Resource Toolkit:

- Decision Matrices: Weighted scoring systems for technical vs. cost factors.

- Failure Mode Library: Database of 500+ material failure case studies.

- Cost Calculator:复制Total Cost = (Material Cost/kg × Part Weight) + Tooling Amortization

Validation Protocols:

- Accelerated Aging Tests: 1,000-hour UV exposure for outdoor material validation.

- Chemical Compatibility Charts: Swell resistance ratings for 200+ chemicals.

5. Recommended Visual Assets for Enhanced Engagement

- Material Selection Flowchart:

- Interactive diagram showing “If-Then” decision paths.

- Alt Text: “Plastic material selection flowchart for product designers.”

- Property Radar Charts:

- Visual comparisons of ABS vs. PC vs. PEI in strength/heat/cost axes.

- Alt Text: “Plastic material properties radar chart comparison.”

- Manufacturing Compatibility Grid:

- Heatmap showing material suitability for injection molding, 3D printing, etc.

- Alt Text: “Plastic material selection guide for manufacturing processes.”

- Sustainability Impact Infographic:

- CO₂ footprint comparison: Virgin PP vs. Recycled PP vs. Bio-PP.

- Alt Text: “Sustainable plastic material selection environmental impact.”

- Case Study Before/After:

- Failed PS part vs. optimized ABS component with failure analysis.

- Alt Text: “Plastic material selection case study results.”