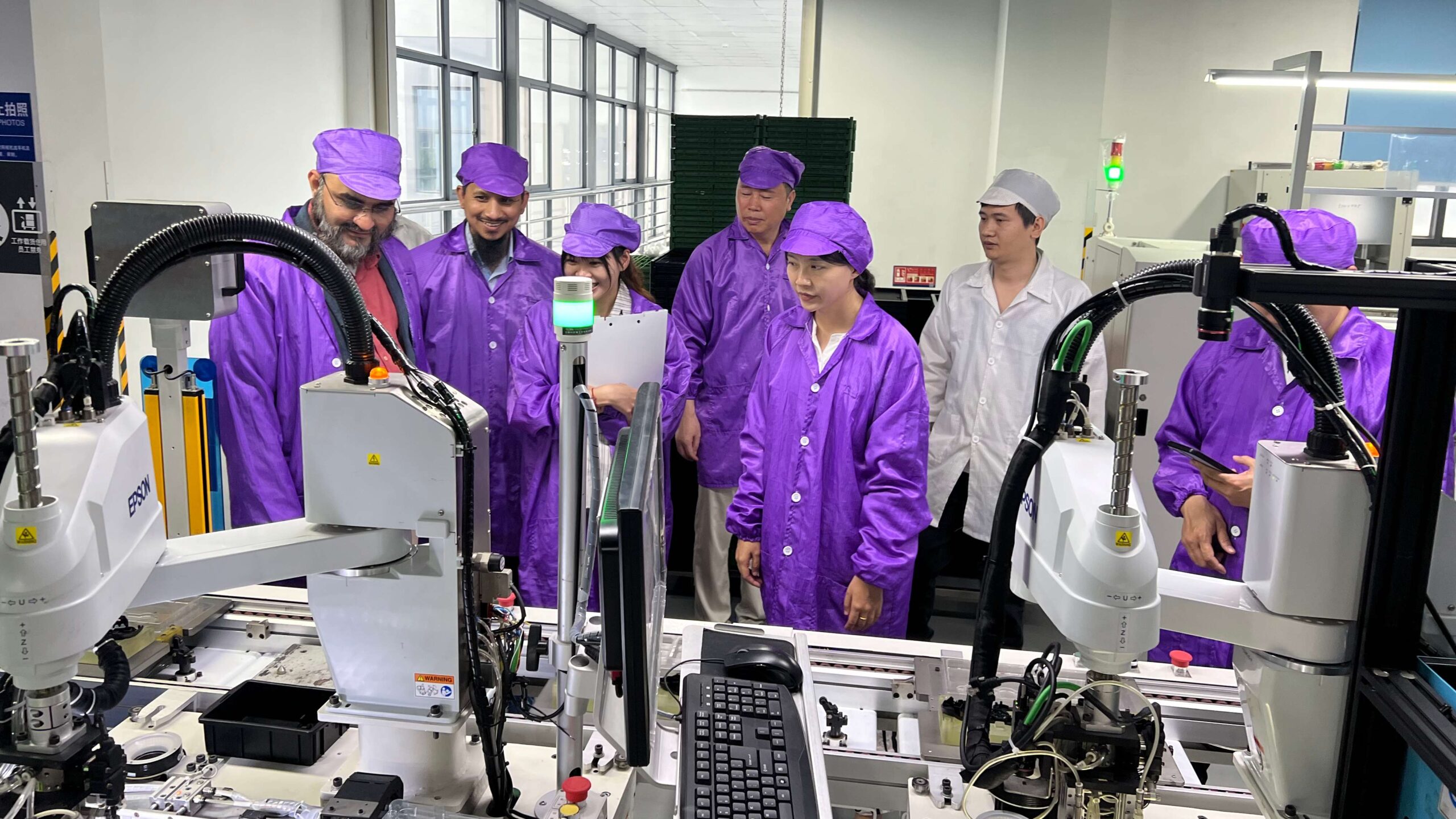

Middle Eastern clients visited OPD-Design to co-create electronic design

Shenzhen, May 8, 2025 — OPD-Design, a global leader in integrated electronics design and manufacturing, hosted a delegation from a premium Middle Eastern brand to accelerate the development of culturally intelligent IoT devices. The collaboration highlighted OPD’s end-to-end expertise—from advanced electronic product design to precision molding and assembly—tailored for the Middle East’s extreme environments and cultural nuances.

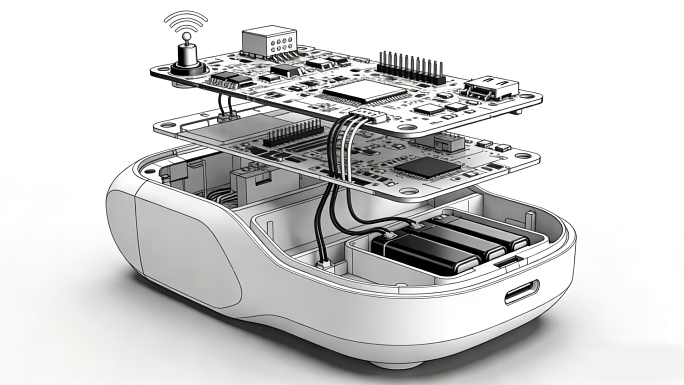

1. Electronics Design Mastery: Engineering Resilience Meets Cultural Intelligence

At OPD’s Shenzhen Electronics Innovation Lab, engineers and clients co-optimized next-gen IoT systems:

A. Extreme-Environment Electronics Design

- Developed multi-layer PCB architectures with ceramic-embedded heat sinks, reducing critical component temperatures by 12°C under 45°C desert simulations.

- Engineered wide-voltage power circuits (100-240V) achieving 94% efficiency, addressing regional power fluctuations.

- Validated dust-resistant sensor modules (IP52-rated) showing <1.5% data deviation in sandstorm simulations.

B. Culturally Adaptive Hardware

- Integrated right-to-left display drivers at the PCB level for seamless Arabic UI rendering.

- Designed hardware-based Ramadan Mode via dedicated MCU circuits, slashing standby current to 10μA for silent operation during prayers.

C. Security-Centric Electronics Design

- Embedded ATECC608B hardware encryption chips for GCC-compliant data protection.

- Implemented EMI-filtered circuit layouts, passing GCC EMC certification in first-round testing.

“Electronics design for the Middle East demands dual mastery—brutal environmental rigor and cultural sensitivity,” stated Dr. Wei Li, OPD’s Director of Electronics Design. “Our patented dual-redundancy thermal circuits exemplify this philosophy.”

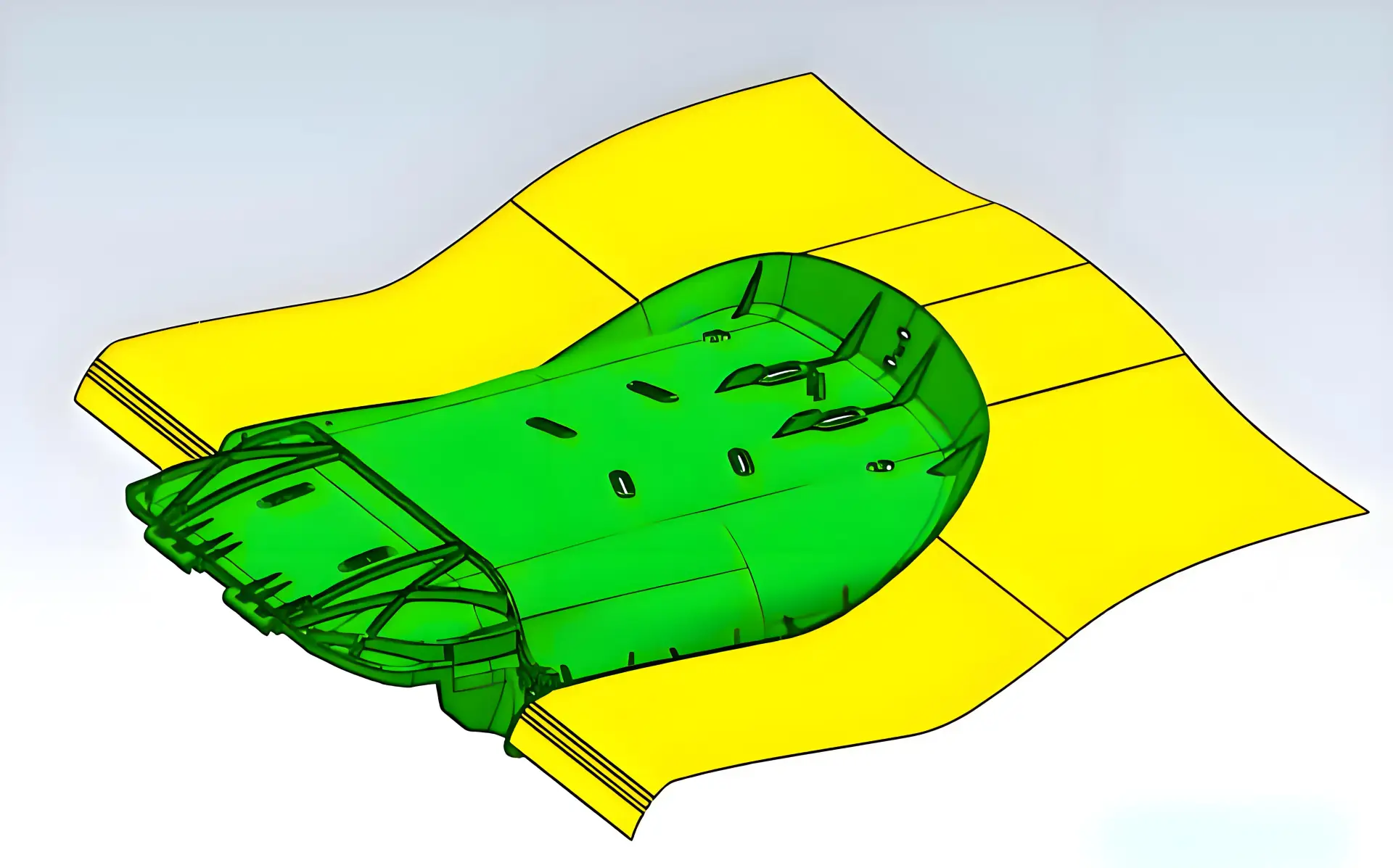

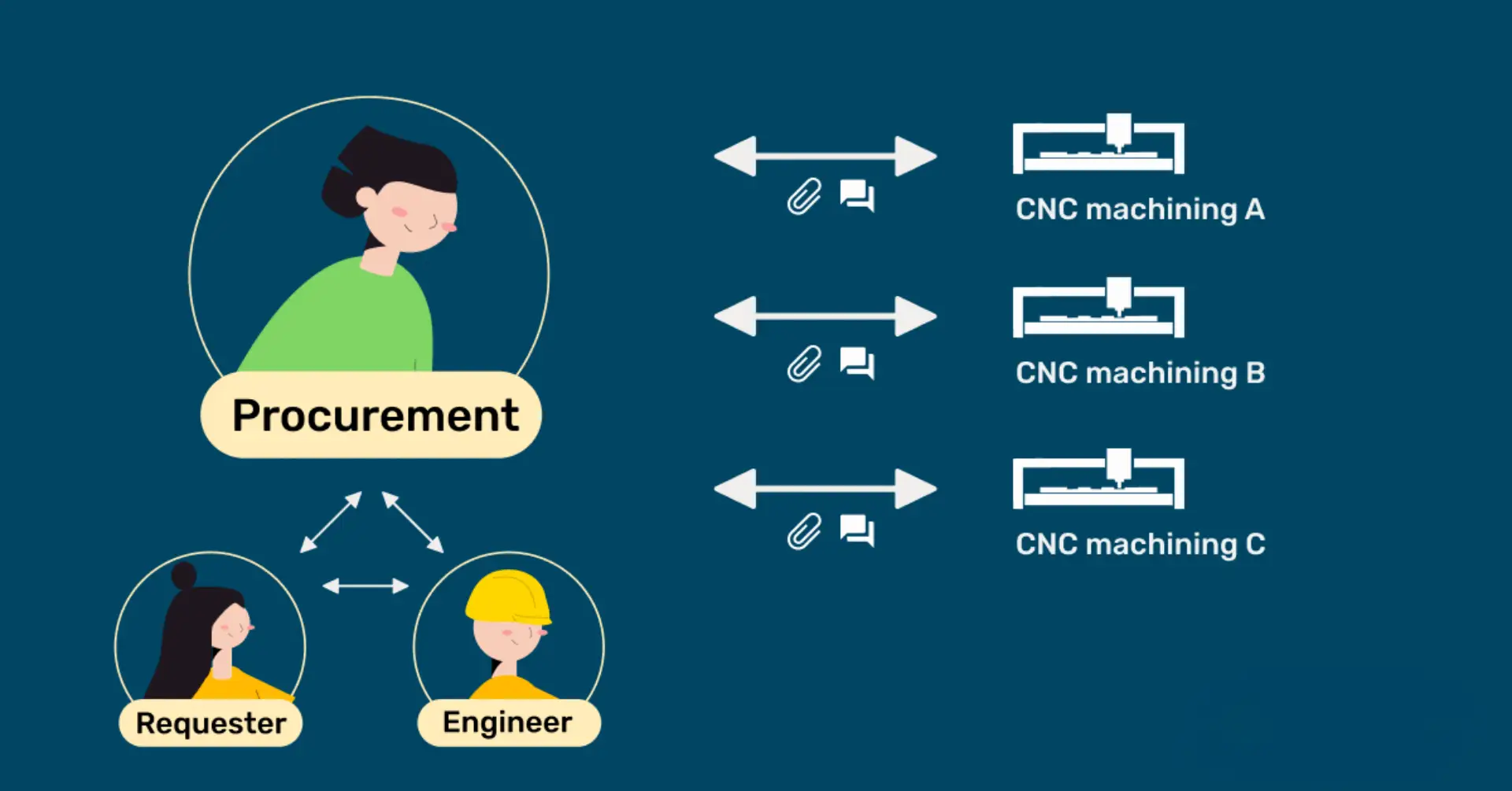

2. Manufacturing Synergy: Bridging Electronics Design with Precision Production

The client audited OPD’s manufacturing ecosystem, verifying seamless translation from design to mass production:

A. Precision Molding & Material Innovation

- Observed 300°C-resistant PPSU housing production using German hot-runner molds (99.4% yield), critical for electronics heat dissipation.

- Tested anti-abrasion coatings simulating 5-year Saharan exposure, exceeding MIL-STD-810H for surface durability.

B. SMT & Electronics Assembly

- Fuji NXT-IV machines placed 0402 components with ±0.025mm accuracy, achieving 99.3% first-pass yield for IoT control boards.

- Validated lead-free reflow profiles (260°C peak) ensuring solder joint reliability in desert thermal cycling.

C. Lifecycle Validation

- Conducted 72-hour 85°C/85% RH stress tests on populated PCBs, showing <0.05% performance drift.

- Executed 20G shock tests mimicking Middle Eastern logistics, with zero component dislodgement.

“OPD’s electronics design-to-production continuum is unmatched,” praised the client’s VP of Engineering. “Their mold-to-PCB co-design approach eliminates traditional DFM bottlenecks.”

3. Strategic Roadmap: Electronics Design as Cultural Catalyst

The partnership launched three initiatives to dominate the Middle East’s $29B smart tech market:

A. Regional Electronics Design Hub

- Establishing a Dubai-based design center with Middle Eastern EDA toolkits, slashing development cycles by 30%.

B. Heritage-Inspired Hardware

- Prototyping Frankincense Compatibility Modules using MEMS-based aroma sensors for cultural relevance.

C. Sustainable Electronics Design

- Piloting bio-based PCB substrates reducing carbon footprint by 40%.

- Implementing EOL (End-of-Life) ICs enabling automated low-energy disassembly.

About OPD-Design

OPD-Design delivers full-spectrum electronic product design and manufacturing services, from concept to GCC-certified mass production. With 31 patents in thermal management and adaptive hardware, we’ve empowered 47 Middle Eastern tech launches since 2022.

Act Now

Explore our business portfolio: www.opd-design.com, LinkedIn

Contact: +86 755 26603660 | hello@opddesign.com