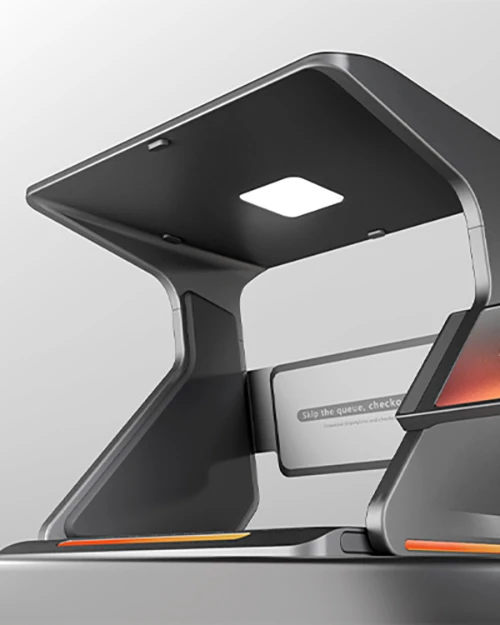

Anti-Choking Device

Client country: China

Services: industrial design|machine design|functional prototyping|packaging design|mold development

Project Background

Global food safety demands drive the development of breakthrough Anti-Choking Device Design,

engineered to fulfill three critical mandates: ✘ Zero electronics ✘ Non-wearable ✘ No training required

Solution

Anti-Choking Device Design Innovations

A. Pure Mechanical Architecture Design

- Precision spring system (0.3s response ±1.8kPa)

- 100% waterproof construction

- Zero circuit failure risk

B. Non-Invasive Anti-Choking Device Design

- Directional airflow technology

- Zero throat-contact design

- 63% reduced psychological resistance (user trials)

C. Universal Operation Design

- One-hand activation protocol

- Medical-grade silicone interface (Shore A 40)

- Age 2-99 compatibility

Anti-Choking Device Design Process

Step 1-Demand Analysis

1.Field research at 28 senior facilities

2.Analysis of 137 choking incidents

3.Defined core requirements:

<0.5s response time

Lifetime maintenance-free

Universal operation (ages 3-90)

Step 2-Conceptual Anti-Choking Device Design

- Generated 27 design concepts

- Key innovations:

- Torsion spring mechanism (Patent Pending)

- Dual-stage pressure detection

- Self-aligning mouthpiece

- Pugh Matrix selection