Having a groundbreaking idea is exhilarating. But the real challenge lies in knowing how to systematically invent a new product and bring it successfully to market. Transforming a concept in your mind into a tangible, desirable object requires a disciplined methodology and professional execution. This guide delves into the complete product design and development process, revealing the key stages that turn creativity into commercial success.

Phase 1: Laying the Foundation: Product Strategy & Validation

Before any design begins, successful product innovation starts with clear strategic planning. This phase aims to validate your idea and map a precise roadmap.

- Deep Market Research & User Analysis: Define your target user and scenarios. Conduct thorough user process analysis to ensure the product solves a genuine pain point.

- Functional Definition & PRD Creation: Translate the idea into concrete functional definitions and a detailed Product Requirements Document (PRD), the blueprint for your team.

- Technical Pathway & Risk Assessment: Evaluate different technical pathways to bring your invention to life, identifying bottlenecks and risks early.

- Cost Estimate & Timeline Projection: Develop initial cost estimates and timeline projections to set a realistic budget and milestones, ensuring commercial viability.

This stage is the decision point for whether to invent a new product. Solid preparation here significantly reduces risk in later product development phases.

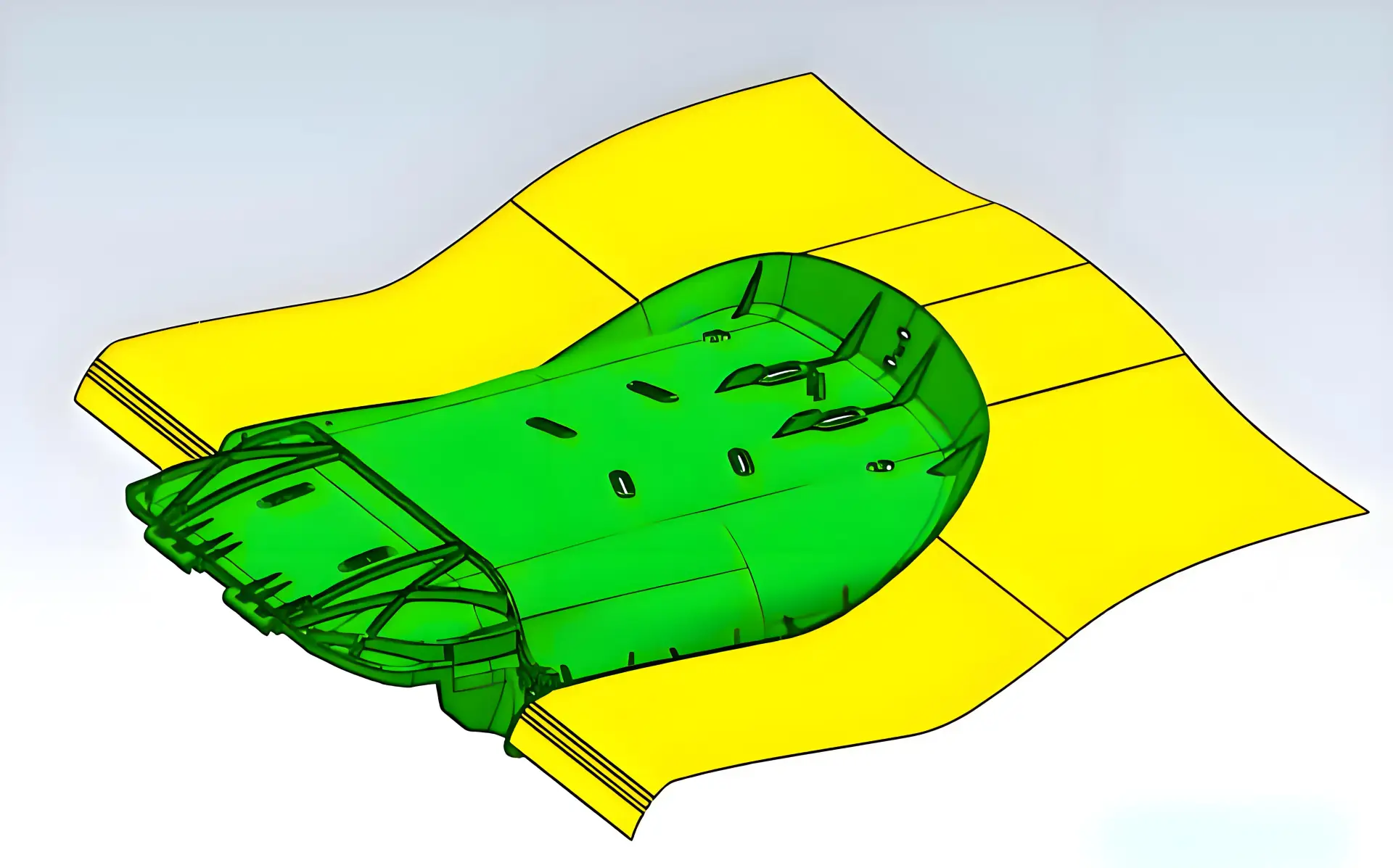

Phase 2: Giving It Form: Industrial & Mechanical Design

With a clear strategy, the focus shifts to giving the product its form and core structure. This is the heart of product design, balancing aesthetics and engineering.

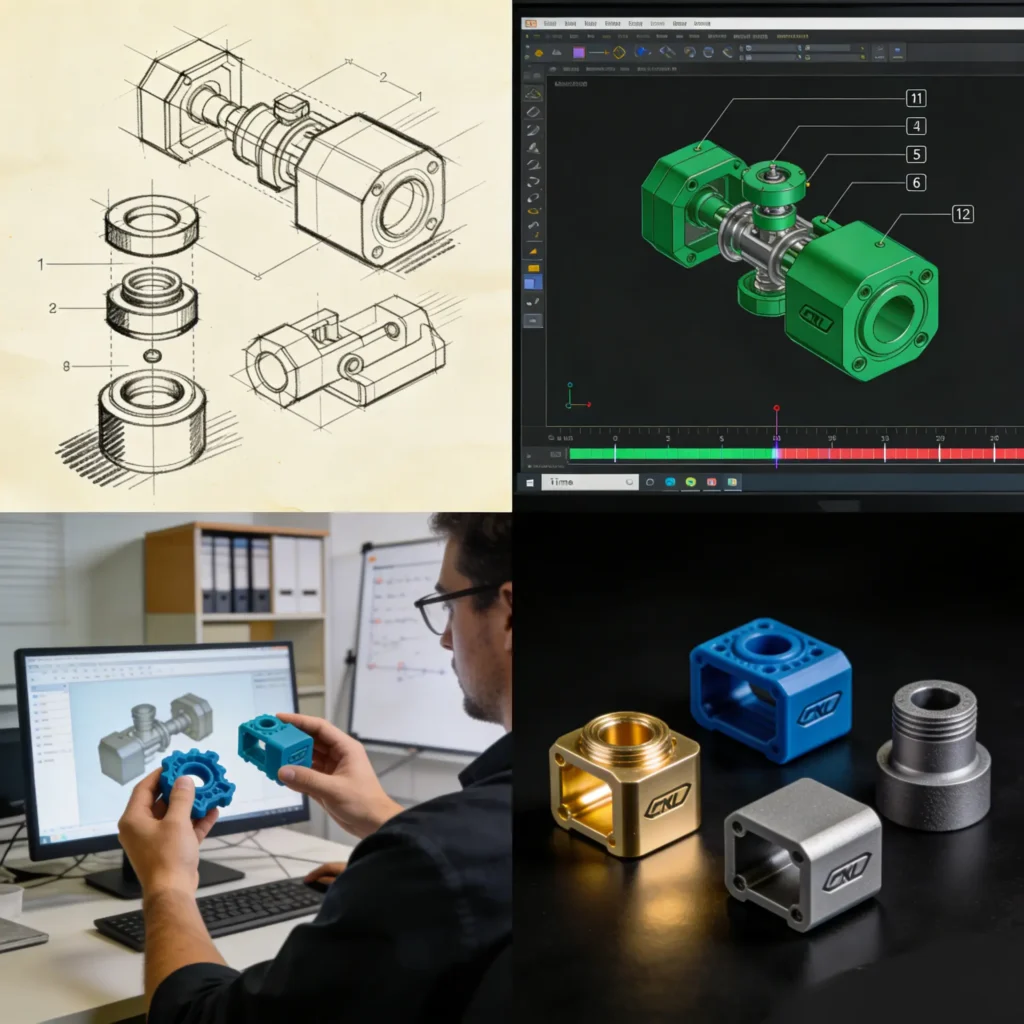

- Industrial Design: Crafting the User Experience: Focuses on aesthetics, ergonomics, and emotional connection. Through sketching, 3D modeling, and rendering, concepts are visualized and brand identity is shaped.

- Mechanical Design: Building the Internal Architecture: Ensures the product is internally stable, reliable, and producible. Engineers perform stress analysis and motion simulation to create a solid physical foundation.

- Rapid Prototyping & Iteration: Rapid prototyping using 3D printing or CNC machining is crucial. Physical prototypes are vital for testing feel, validating assembly, and gathering feedback, often requiring multiple iterations.

- Designing for Manufacture: Incorporating Design for Manufacturability (DFM) principles early and conducting mold flow analysis ensures the design is optimized for efficient, high-quality mass production.

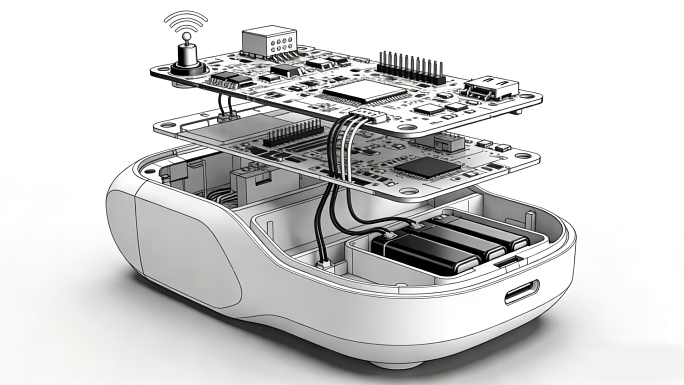

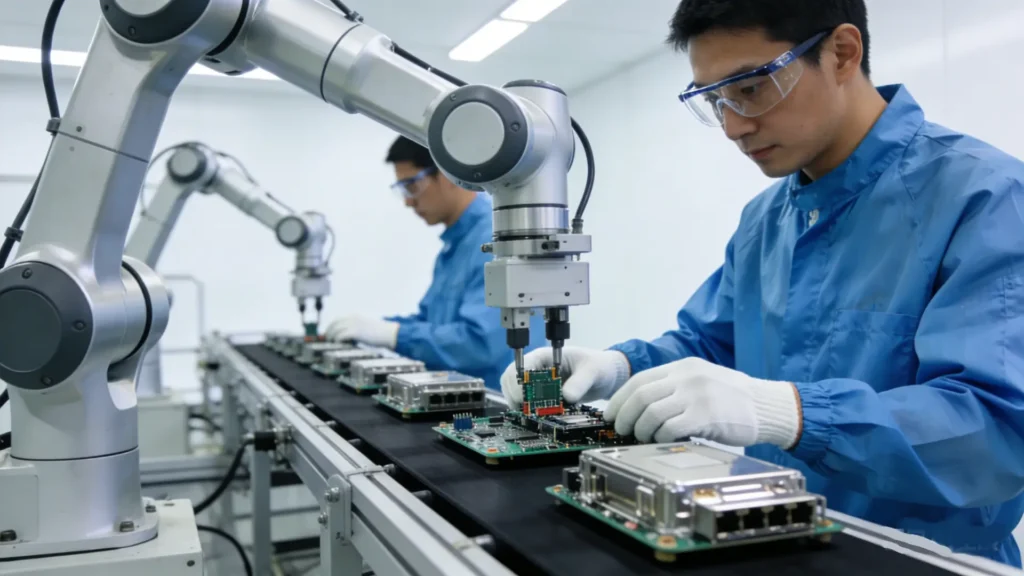

Phase 3: Making It Smart: Hardware & Software Integration

For smart or IoT devices, hardware and software integration is the core of your new product invention.

- Hardware Development:

- Component Selection & Circuit Design: Performing careful component selection and designing the circuit schematic form the electronic foundation.

- PCB Layout & Prototyping: Completing the PCB layout and assembling a PCB prototype for testing.

- Firmware Development & Debugging: Writing embedded firmware to drive hardware functionality.

- Software Development:

- User Interface & Application Development: Designing an intuitive User Interface (UI) and developing companion mobile applications or IoT platforms.

- System Integration & Testing: Conducting comprehensive system integration and functional testing to ensure seamless, stable performance.

Phase 4: Complete Delivery: From Packaging to Mass Production

The final user experience extends beyond the device to the unboxing and beyond.

- Packaging & Brand Visual Design: Creating package structural design and graphics that align with the brand visual identity, enhancing the unboxing experience.

- Pilot Run & Production Ramp-up: Before full-scale mass production, a pilot run validates the manufacturing line, process, and supply chain.

- Supply Chain Management & QC: Leveraging a network of over 300 cooperative factories ensures professional supply chain management and quality control for on-time, high-quality delivery.

Conclusion: Partnering for Innovation

To invent a new product is a complex system engineering project requiring perfect synergy between strategy, design, engineering, and production. Partnering with a full-service firm like OPD Design, with end-to-end capabilities and rich supply chain resources, minimizes your innovation risks and maximizes success. If you have an idea poised to change the market, let us help you bridge the gap from concept to commodity.