Many times, when individuals think of a great product, they see a completed object in their hands. Perhaps it is the newest technological accessory, a kitchen gadget, or a smartphone. Few, however, pause to consider how that item was originally created to function in a real manufacturing setting. Design for manufacture fits here.

What Is Design for Manufacture?

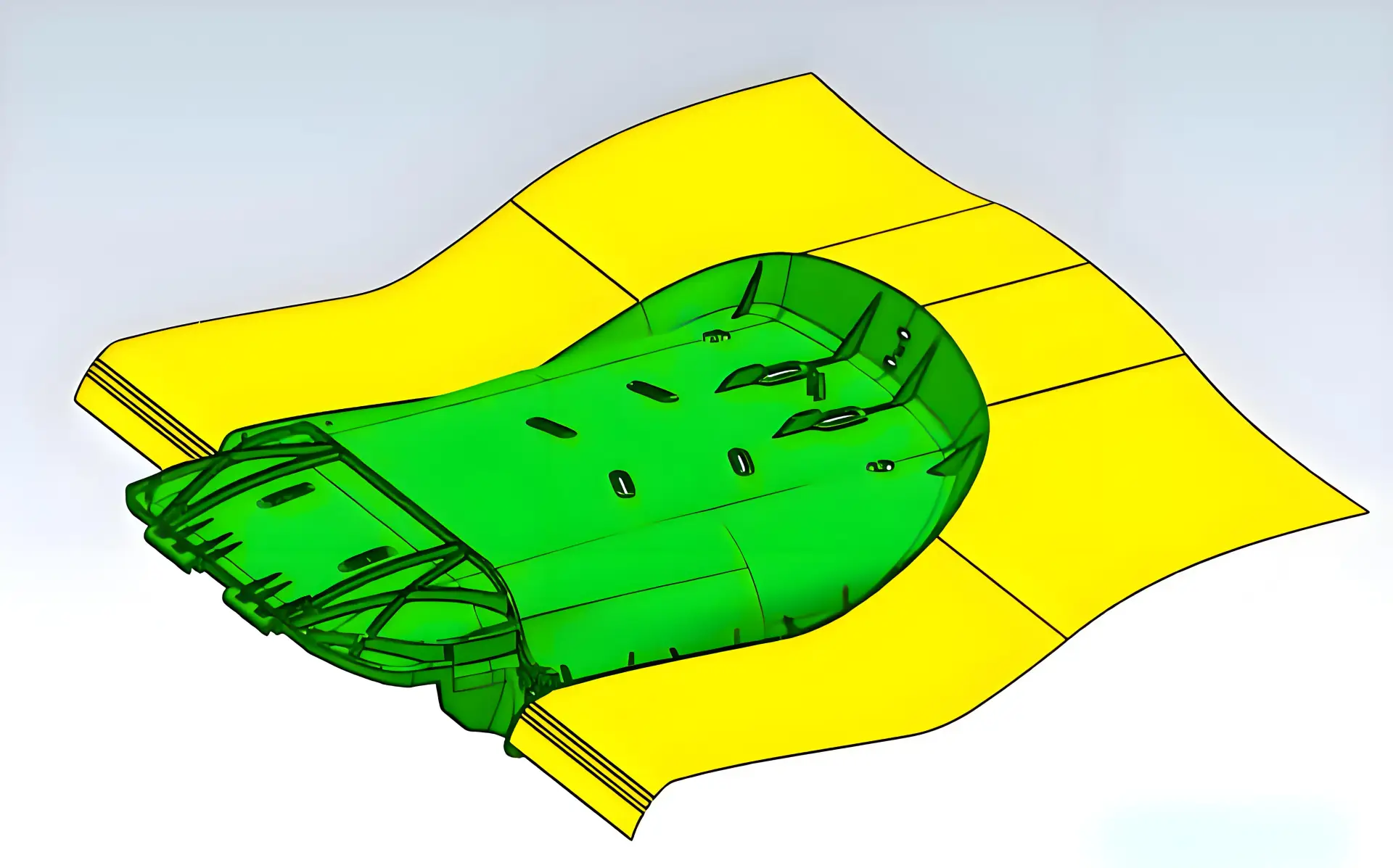

Sometimes known as DFM, design for manufacture is the process of designing goods that are quicker, less expensive, and simpler to produce. It links the reality of manufacturing with product design. Every decision—from the material to the form to the little details—is made with actual factories, tools, and supply chain operations in mind.

In simple terms, it means considering how you will create the product while still designing it. It is about more than simply the appearance or operation of the product. It is about ensuring it can really be produced effectively without wasting time, resources, or money.

Why Design for Manufacture Matters So Much?

You may question why this is significant. Is not a factory, after all, supposed to know how to produce something? The reality is that designing a product without considering how it will be manufactured invites all sorts of issues down the line.

Imagine, for instance, creating a component with difficult-to-reach conventional cutting tools tiny, sharp angles. The factory could have to use more expensive specialized tools. They could also have to reduce output to fit close tolerances, which would take more time. Multiply that by thousands of units in bulk manufacturing, and suddenly the whole project becomes far more costly than intended.

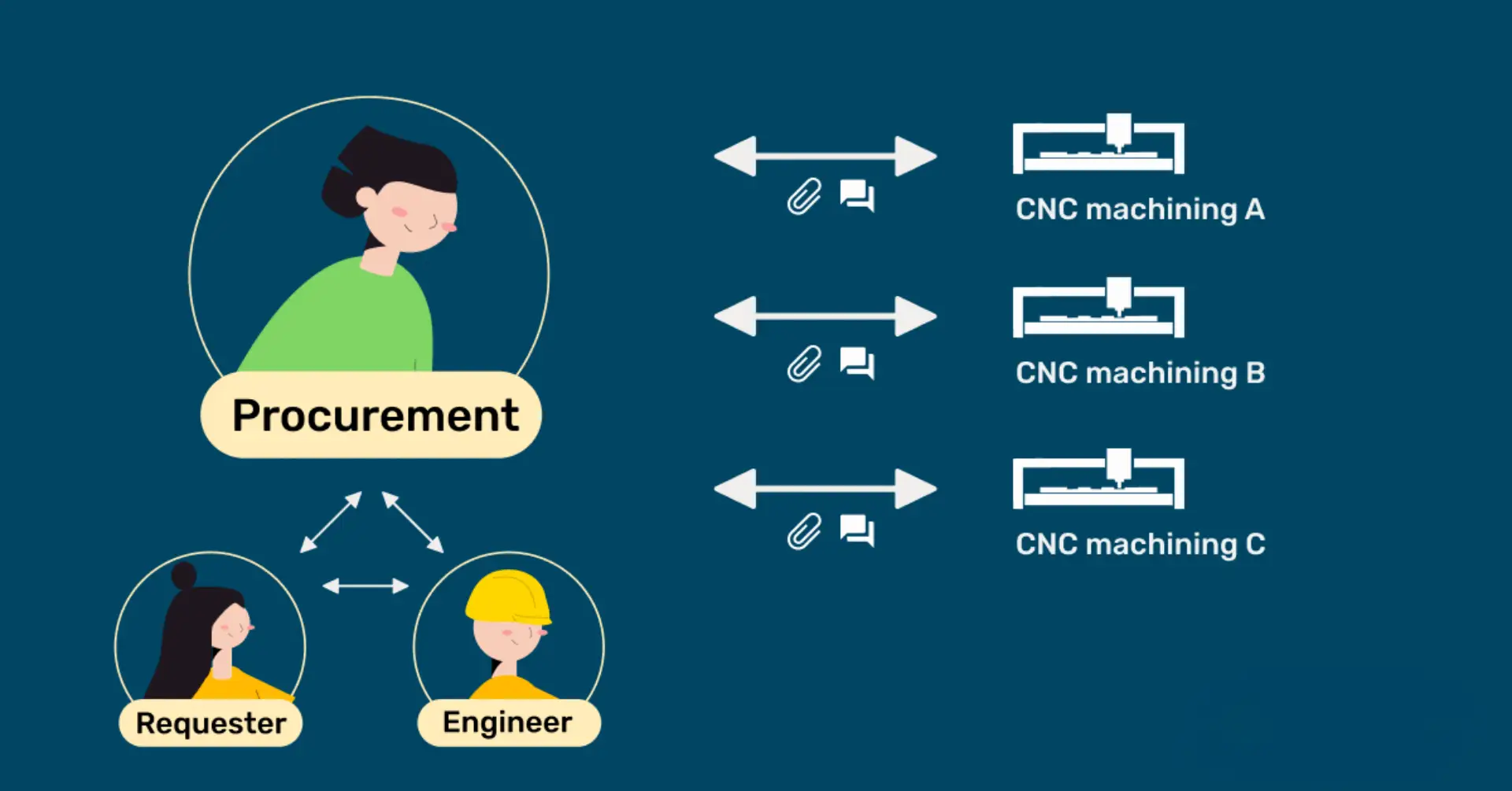

Focusing on design for manufacture from the beginning helps to eliminate these issues. You enable the supply chain manager to plan more effectively. You speed up bulk manufacturing. You also prevent unpleasant shocks that might postpone your launch.

Saving Money Without Cutting Corners

Cost savings is one of the main advantages of design for manufacture. But it is not about using inexpensive materials or skimping. It is about intelligent design decisions that fit actual manufacturing techniques.

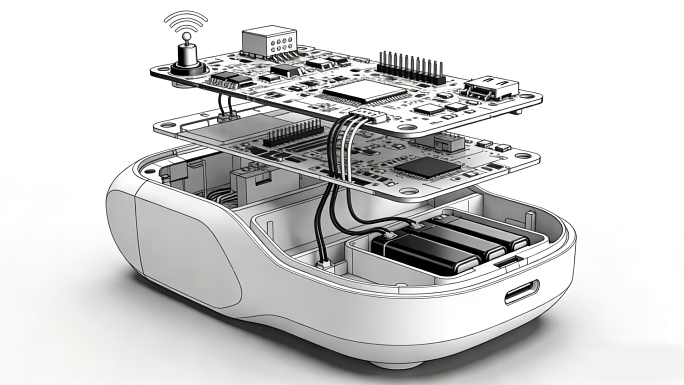

Imagine you are creating a smart home device. The outer shell has two choices. One is a beautiful, intricate form that calls for a bespoke mold costing tens of thousands of dollars but looks fantastic in a design sketch. The other is a more basic form that still looks nice but can be made using conventional molds now in use in high production lines.

Both designs are effective. Both are attractive. But one will deplete your funds even before you begin selling. The other allows you to spend more on packaging, marketing, or including additional features consumers value. Design for manufacture enables you to identify these options early on so you may cut costs where it is logical.

Making Life Easier for the Supply Chain Manager

Getting any product to market depends on supply chain operations. From raw material procurement to shipping and storage control, it is a difficult task. No supply chain manager wants last thing a product that creates problems at every stage.

Designing with manufacturing in mind helps everyone engaged in supply chain activities to have easier life. You select readily available materials. You stay away from components needing uncommon parts. Your packaging design safeguards the item without adding more room in shipping containers. From the factory to your consumer, these little decisions accumulate to create a quicker, more seamless route.

Speeding Up Bulk Production

High production levels imply producing thousands, occasionally millions, of the same item. Running machines all day and night makes every second count. Design for manufacture guarantees the product fits the production line exactly, therefore accelerating this process.

Imagine it like restaurant cooking. The kitchen slows down if every dish calls for a different pan, knife, and ingredient. Designing the menu to utilize the same tools and components for several dishes will help the kitchen to run like a well-oiled machine. Manufacturing is the same concept. Your design’s fit with standard production tools and processes determines how quickly you can expand to satisfy demand.

Reducing Risks in Product Development

Product development is fraught with hazards. You could run into unanticipated expenses, manufacturing delays, or design flaws. Design for manufacture reduces these risks by pushing you to consider ahead.

For instance, suppose you create a snap-fit case for a wearable device. On the computer, it seems ideal. The snaps, however, do not hold together when the first prototype comes. You must return to the drawing board, wasting months or even weeks.

A team knowledgeable in design for manufacture would have been able to identify that problem early if you had collaborated with them. Perhaps they would have included more tests throughout prototyping or recommended a different snap design. You would find the issue either before it turned into an expensive error or before it started.

Better Quality, Happier Customers

Customers value excellence. They seek items that last a long time, operate well, and feel strong. Here, too, design for manufacture is quite important.

Designing a product to match the strengths of the manufacturing process will help you to achieve more consistent outcomes. Components complement one another more. Surfaces are more smoother. The product functions as intended straight out of the box. That translates to less complaints, less returns, and more satisfied consumers.

Imagine a consumer purchasing a phone charger that breaks apart after two weeks. Your brand will not be trusted by them once more. But if the charger feels solid and works flawlessly for years or months, they are more likely to suggest it to friends. Design for manufacture increases product quality from the beginning, therefore helping you to establish that confidence.

Faster Time to Market

Timing is everything in the fast-moving market of today. Your chances of remaining ahead of rivals improve the earlier you start. From early designs to large production, design for manufacture accelerates every stage.

Thinking about production as you design helps you to prevent delays later. You spend less time redesigning. You have less trouble with suppliers. You may also begin mass manufacturing earlier. Your product therefore reaches the shelves more quickly, which helps you to be more competitive.

Final Thoughts

Design for manufacture is more than simply a nice-to-have. Smart product development depends on it as its backbone. It enables you to provide better products to your consumers, accelerate manufacturing, and cut costs. Thinking about manufacturing early makes all the difference whether you are creating your first product or expanding up to high production.Ready to bring your next product idea to life the smart way? Visit OPD Design today to discover how we can help you design for manufacture and win in your market.