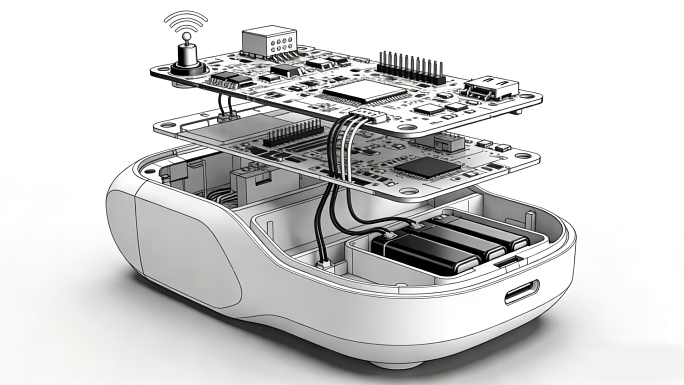

If you look closely at almost any plastic product around you – your phone, remote control, or kitchen appliance – you’ll notice subtle lines grooved into its surface. These aren’t mere decorations; they are meticulously designed split lines, a critical feature that blends function, manufacturability, and aesthetics. Often called a “cosmetic line” or “decoration line,” understanding the split line is essential for anyone involved in product design, engineering, or manufacturing.

Why Your Plastic Product Needs a Split Line

1. Mechanical & Functional Reasons

Split lines solve common physical challenges in assembly and user interaction.

- Uniform Appearance Gaps: During injection molding, large or curved shell edges can warp or deform. When assembled, this can lead to uneven and unsightly gaps between the upper and lower housings. A intentionally designed split line provides a controlled gap, making any natural variation in the assembly much less noticeable to the human eye. A wider split line effectively hides this unevenness better.

- Reduced Scratch Sensation: A warped shell can create a sharp step between parts. When a user runs their finger over this step, it feels sharp and unpleasant. The split line mitigates this by increasing the angle (α) at which the finger contacts the edge. This reduces the horizontal component of force acting on the skin, significantly lowering the unpleasant “scratch feel.” A rounded corner design at the edge further reduces pressure by increasing the contact area, enhancing the user’s tactile experience.

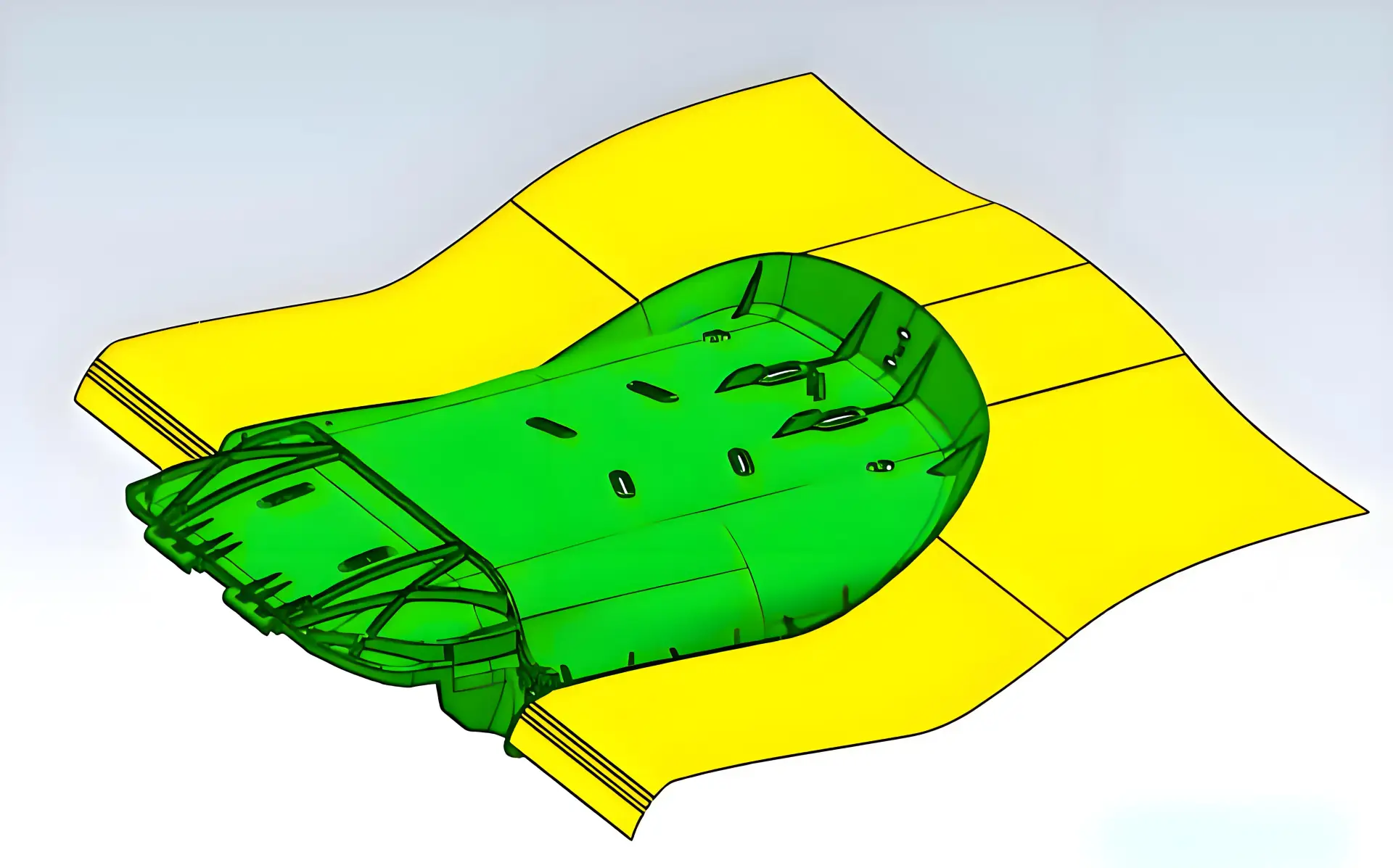

2. Manufacturing & Process Needs

Split lines are often indispensable for achieving high-quality mass production.

- Preventing Paint Overspray: When different colors need to be sprayed on adjacent areas, a deep, sharp split line acts as a physical barrier. It allows for easier masking with fixtures (jigs), preventing paint from bleeding or overspraying onto the adjacent section. This groove also captures potential paint accumulation, ensuring the color dividing line looks crisp, straight, and clean. Without it, achieving a perfect line is extremely difficult and often results in a messy, zig-zag boundary.

- Hiding Mold Parting Lines: The parting line where the two halves of a mold meet often leaves a faint witness line on the final part. A strategically placed split line can hide this unavoidable artifact within its groove, maintaining a clean aesthetic. Similarly, lines from mold inserts (e.g., for a brand logo) can be concealed in a split line. This allows manufacturers to use the same base mold and simply change the insert for different clients or products, saving massive tooling costs.

3. Aesthetic & Decorative Effects

Beyond pure function, split lines serve an artistic purpose.

- Visual Enhancement: Large, flat surfaces can look bland and rigid. A well-placed split line breaks up the monotony, adds visual hierarchy, and creates compelling light-and-shadow effects, strengthening the product’s overall visual appeal.

- Functional Aesthetics: Sometimes, the line serves a dual purpose. A split line can be textured for grip on a handheld device or raised to provide a finger grip for opening a battery cover.

Types of Split Lines

| Type | Primary Purpose | Description |

|---|---|---|

| Structural / Mechanical | Function & Assembly | Designed at the mating edge of two parts. It manages gaps, steps, and deformation caused by molding and assembly tolerances. |

| Process | Manufacturability | Includes paint mask lines for color separation and mold process lines to hide ejector pin marks, slider lines, or other mold artifacts. |

| Decorative | Aesthetics | Primarily used to enhance the product’s visual design through grooves, patterns, and textures. |

Key Considerations for Split Line Design

- Managing the Step: Even with a split line, a slight step between parts may exist. Designers typically prefer an “outer surface scrape” where the outer shell is slightly larger (by 0.1-0.15mm) than the inner shell to control the visual perception of this step.

- Width vs. Depth: From a mold-making perspective, a wider and shallower groove is always easier and cheaper to machine than a narrow, deep one. Design with the widest, shallowest acceptable groove your aesthetics allow.

- Avoid Sharp Corners: The cross-section of the groove should not be a perfect rectangle. Sharp internal corners are stress concentrators, difficult to polish, and prone to trapping dirt. A rounded bottom radius is essential for improving durability, simplifying mold maintenance, and making the product easier to clean.

Conclusion: The Unseen Hero of Design

The split line is a perfect example of how brilliant design lives in the details. It’s a fundamental feature that elegantly resolves the inherent conflicts between design intent, material behavior, and manufacturing realities. A well-executed split line is invisible to the consumer—but its absence, or poor execution, is immediately obvious to the eye and the touch. It is a small feature with a massive impact on the quality, feel, and manufacturability of a product.

- Did you find this guide helpful? Have you encountered a product where the split line design particularly impressed (or disappointed) you? Contact us