It’s not simple to bring a fresh concept to reality. It’s seldom a direct route. From vague ideas to actual, functional, marketable products, the new product development process is the road map guiding businesses. Whether you’re improving an already-existing solution or designing a brand-new technology, knowledge of every stage in the process can greatly help.

It guarantees you are creating what consumers really want, saves time, and reduces risks. This article will teach you how companies, especially those providing product design and development services—make wise decisions to successfully and smoothly bring their goods to market.

Understanding the New Product Development Process

Starting with a raw concept and finishing with a completed product in users’ hands, the new product development process is a journey. It does not follow a strict formula. Rather, it changes based on the market, objectives, and resources available. The goal is still to produce valuable, feasible, and customer-centered goods by means of a consistent process.

It calls for a combination of imagination, strategy, testing, and implementation. Whether you’re introducing a domestic item or a tech gadget, following the correct design process stages will help you prevent expensive mistakes.

Begin with Purposeful Ideation

Every new product begins with a challenge. Ideation is about clever thinking, not only about thinking large. That calls for searching for unmet demands, market gaps, or pain areas present solutions do not address.

Studying trends, paying attention to user input, or exploring competitor analysis helps some of the most successful businesses to get inspiration. Rather of pursuing glitzy concepts, they concentrate on those based in reality issues. Innovation is sometimes about enhancing what is currently available rather than creating something fresh.

A clever idea generation stage organizes creativity. Teams should gather ideas from all across engineering, marketing, sales, and customer support at this point in the new product development process. A more varied input will help to round your product concept.

Screen Ideas Before You Build

Some ideas are not worth pursuing. Screening fits in there. You must distinguish between the far-fetched and the practical. The product development path has a key checkpoint in this one.

Idea screening is the process of determining whether there is genuine market demand, whether it can be constructed using present technology, and whether it complements your company strategy. Many times, businesses use cost-benefit models or SWOT analysis during this phase.

An idea, for instance, could not be worth pursuing if it costs too much to manufacture or would not stand out against the competition. Even good concepts need examination; that’s how you prevent time and financial loss.

Build Concepts, Then Test Them

Once a strong idea is chosen, the following stage is concept creation and testing. This is when teams transform more obvious product visions from abstract concepts. They could build early prototypes, digital mockups, or drawings. The aim is to identify the fundamental qualities and value of the product.

Now is also the moment to challenge assumptions. Real people provide comments on how the product could fit into their life. Does it address their issue? Is it user-friendly? Would they purchase it?

Testing early and frequently throughout this phase of the new product development process helps teams to clarify their path before committing to costly manufacturing. By providing fast prototyping and technical feasibility assessments, product design and development services can also significantly influence this area.

Invest in Detailed Design and Engineering

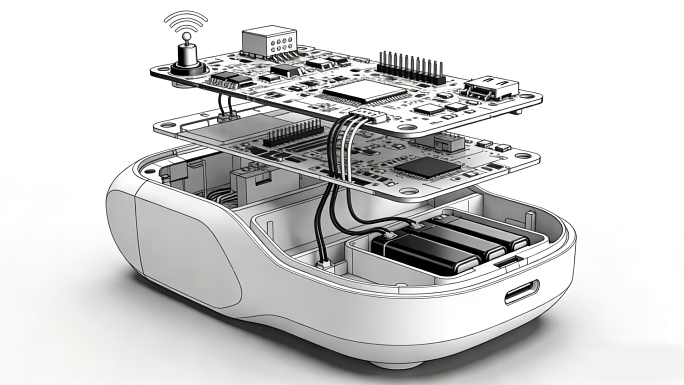

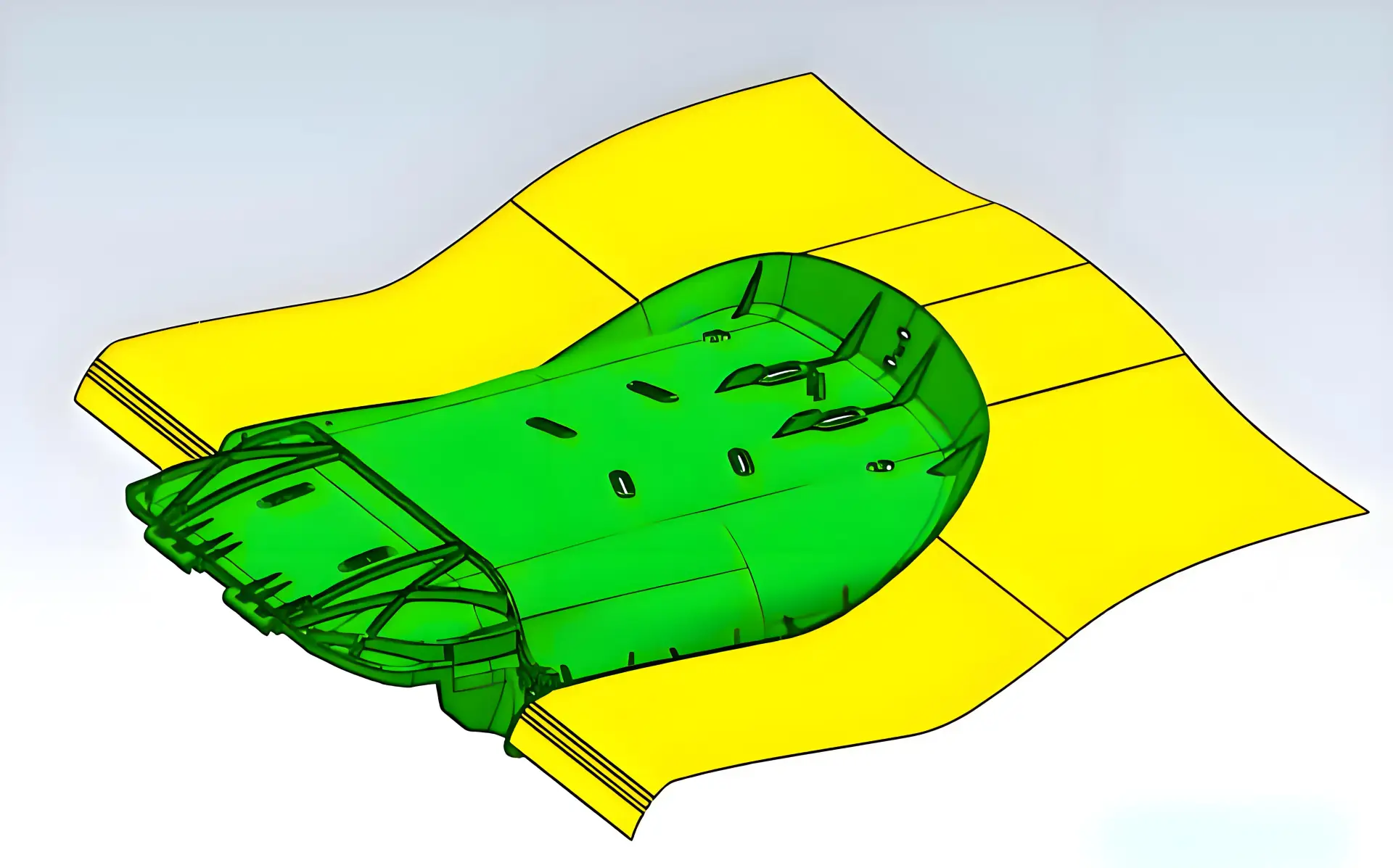

Once the idea is confirmed, it’s time to convert it into a genuine, buildable product. Detailed engineering and design process phases include 3D modeling, material selection, and production of technical drawings are common at this point.

Industrial design determines the look and feel of the product. Mechanical and electronic design guarantee the product will work well and can be manufactured effectively. Good design strikes a balance between manufacturing expense and utility.

Our Shenzhen team, for instance, integrates product design and development services to maximize both form and function. Every part’s fit into the larger picture gets our keen consideration. By the time we hand over to prototyping or tooling, that guarantees no surprises.

Safety inspections, industry compliance assessments, and internal stress testing are common components of this stage assuring the product satisfies legal and technical criteria.

Develop and Test Prototypes

Strong design won’t tell you how a product works until it’s created. Prototyping is therefore quite crucial. Imagine it as dress rehearsal prior to the last performance.

Prototypes let teams touch, test, and stress the design in the actual world. They assist in confirming durability, usability, and ergonomics. Complex products might have several versions created and evaluated with various user groups.

Recent statistics show that early prototyping firms are 47% more likely to reach their launch objectives. They respond fast and spot problems early, so

Prototypes let investors and stakeholders also view something real. It increases confidence and guarantees more money or buy-in.

Prepare for Manufacturing and Scalability

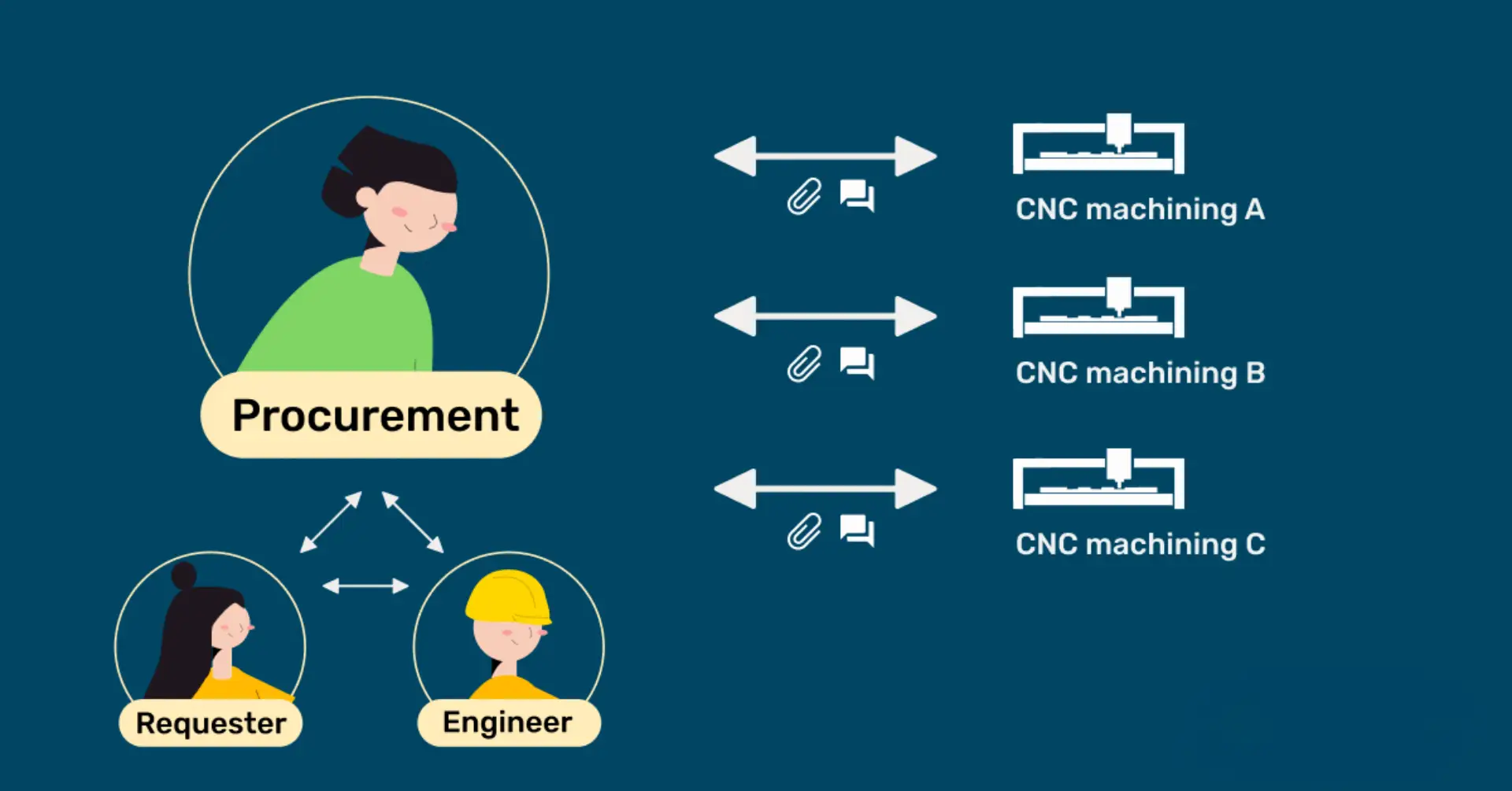

Once a workable prototype is authorized, mass manufacturing can be planned. But you don’t just leap in. Here is where product development services come in to maximize the design for manufacturability, sometimes referred to as DFM.

Every supplier, method, and material has to be examined. Will the product last at scale? Can we get parts in plenty? How about cost per unit?

This is also when supply chain planning starts. The success of the product after launch is influenced by selecting the appropriate suppliers, estimating lead times, and inventory forecasts.

Many businesses in China at this point, particularly in manufacturing centers like Shenzhen, rely on local networks to obtain parts, examine molds, and even design packaging. For instance, our staff provides complete product design and development services, therefore enabling customers to save money while preserving great quality.

Launch and Learn

The product eventually reaches the market after all the effort. But this is not the finish line; rather, it is another start. Launching a product entails rolling out promotion, establishing distribution, assisting consumers, and tracking comments.

Harvard Business Review statistics reveal around 75% of product launches fall short of expectations. The main causes? Misunderstanding the market, bad timing, or insufficient messaging.

Early consumer feedback collection, monitoring of usage trends, and readiness to change are all crucial since they help to clarify the market. Improvements after launch can determine long-term success or failure.

Real user insights help to enhance not just the product but also your whole new product development approach. Over time, this feedback loop distinguishes great organizations even more.

Why the New Product Development Process Matters More Than Ever

Speed and accuracy are important in fast-moving marketplaces. The new product development approach organizes the mayhem. It enables teams to concentrate on what really counts by guiding them away from guesswork: using functional products to solve actual issues.

For businesses like ours that provide one-stop product design and development services, this organized strategy guarantees quicker turnarounds, less prices, and better outcomes for customers. From concept to launch, we assist companies all over the world create better products.

Having a flexible yet dependable approach is no longer optional as product life cycles shorten and consumer demands rise. It’s required.

Conclusion

The new product development approach is a means to create smarter, fail less, and achieve quicker rather than only a checklist. Every stage counts from concept to execution. It calls for diligent planning, intelligent design, actual testing, and ongoing education. Following a defined process helps you stay on course whether your first product or your hundredth. In a volatile industry, it provides your team the skills and clarity to create goods people really want—and to do it without wasting time or money.