Industrial and product design are two fields of study that shape every physical object individuals deal with daily. From packaging and furniture to electric scooters and smartphones, these two domains influence how things look, feel, and operate. Although many consider them distinct sectors, their convergence is where real creativity occurs.

Companies that effectively combine industrial and product design in today’s quick-paced economy produce valuable items and provide significant user experiences. This article investigates how user-centered thinking and cutting-edge technology link various sectors, shape contemporary production, and satisfy rising market needs.

Understanding Industrial and Product Design

Though they reflect different emphasis inside the design sphere, industrial and product design are sometimes used interchangeably. Traditionally, industrial design is the creation of items meant for mass manufacture. It emphasizes user engagement, manufacturability, and functional optimization. Although product design overlaps in many respects, it reaches a more general viewpoint. It covers everything from the idea of a product to its usage, experience, and disposal.

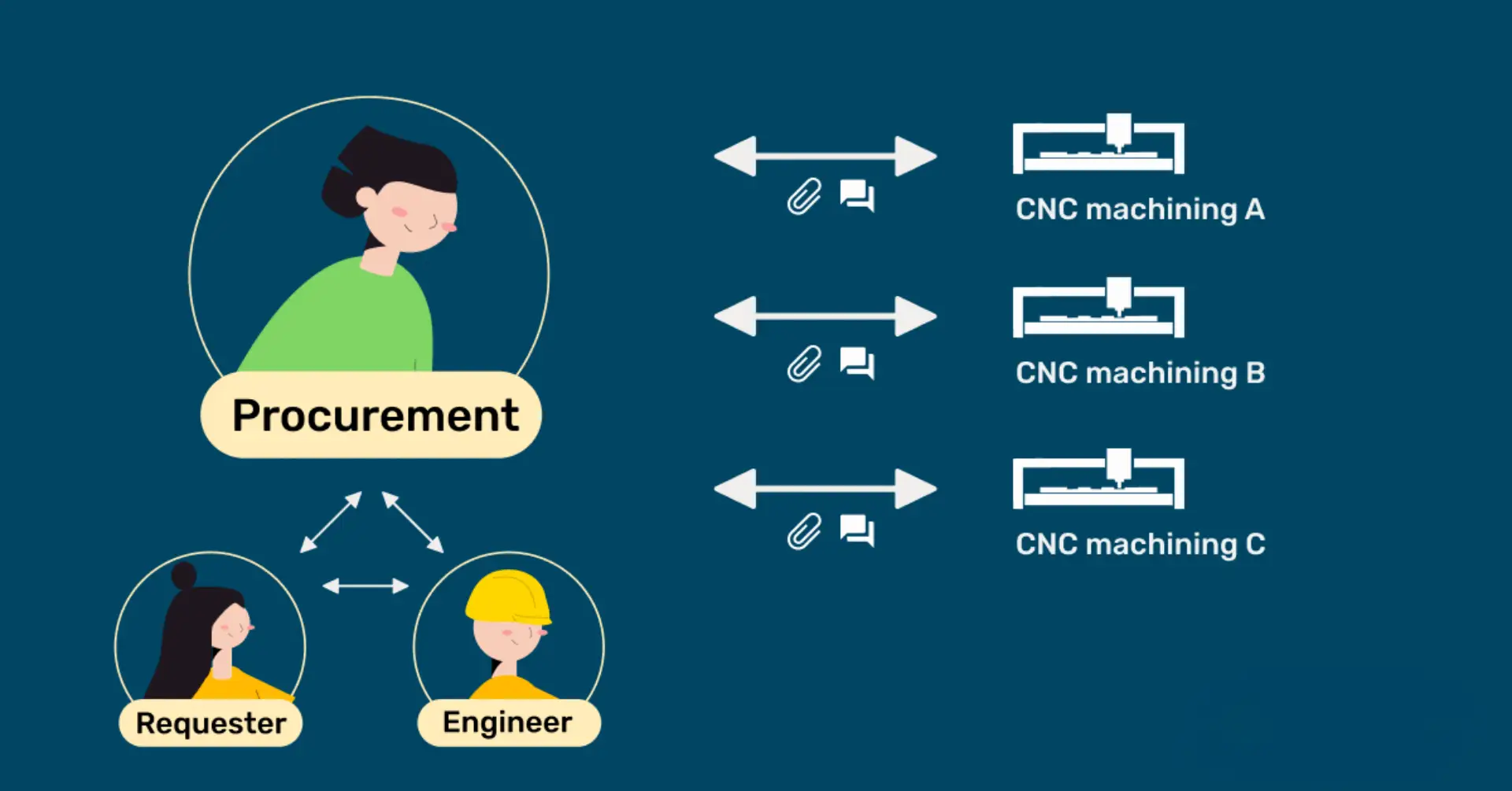

Industrial designers, for instance, usually focus on ensuring a product is durable, affordable, and simple to manufacture in large quantities. Product & design teams could zoom out to encompass the whole user journey, branding, and customer experience. Engineers, designers, and marketers must work together in both disciplines. A project’s success hinges on the capacity to strike a balance between manufacturing viability, utility, and aesthetic appeal.

The Industrial Design Centre as a Hub for Innovation

The industrial design centre is one location where industrial and product design converge. These centers are focal points for cross-functional cooperation among business strategists, engineers, and designers. Such hubs are handy in areas recognized for manufacturing, like Shenzhen, China. Situated in the center of one of the most significant industrial ecosystems in the world, businesses here enjoy direct access to suppliers, manufacturers, and logistical partners.

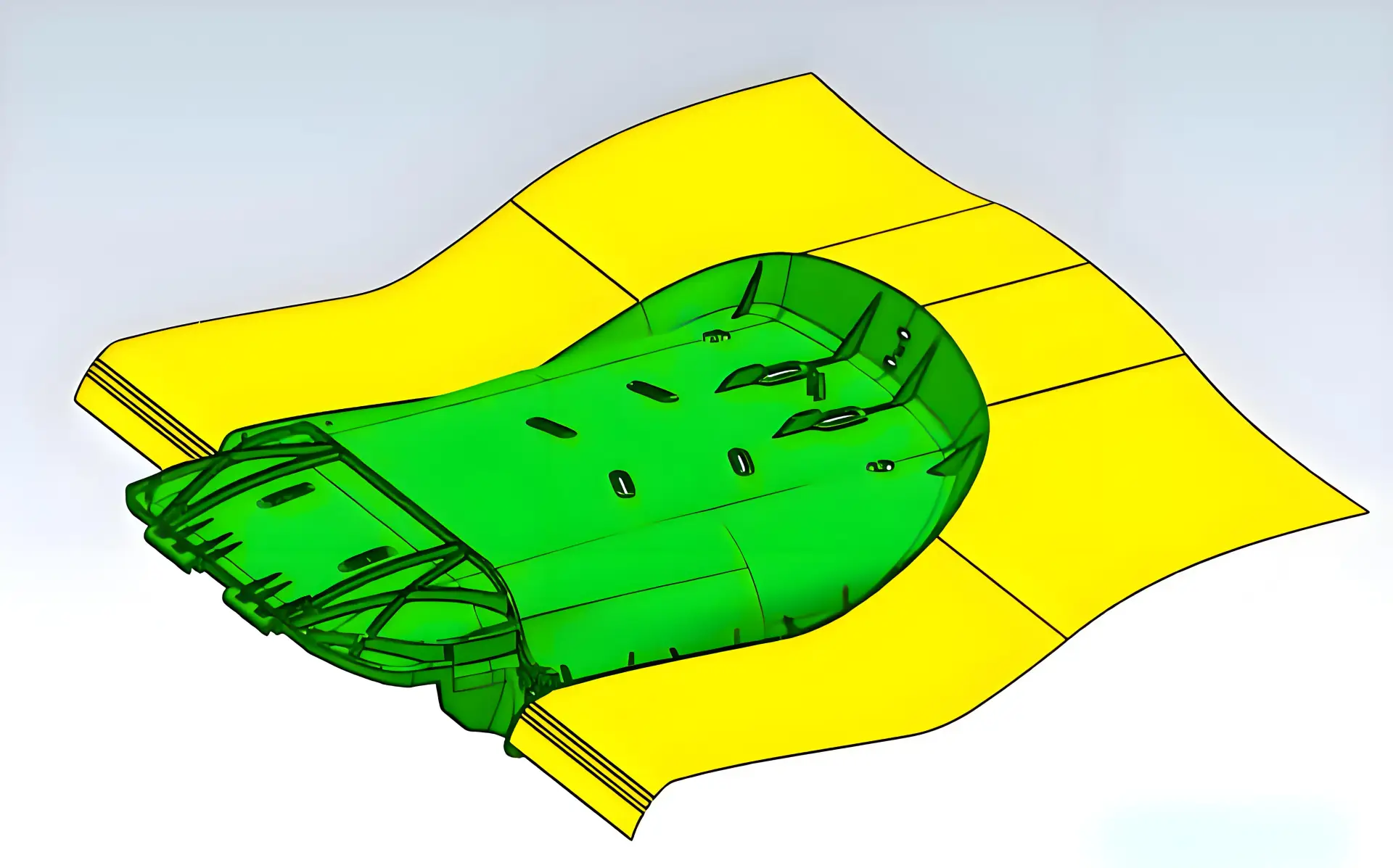

Usually, an industrial design centre has testing facilities, prototype studios, 3D printing workshops, and research labs. These tools enable groups to convert concepts into something ready for sale. Having all these features in one location accelerates the process, minimizes mistakes, and allows designers to to confirm ideas rapidly. This intimate integration of industrial and product design speeds time-to-market and enhances product quality as well as consumer pleasure.

The Role of Industrial Designers in Product Development

In the manufacturing sector, industrial designers are problem-solvers. From concept to reality, they transform abstract ideas into useful and aesthetically pleasing tangible things. Working directly with engineers, they ensure that every part fits together exactly. Industrial designers look at every aspect, from the curve of a smartphone edge to the grip of a power tool handle.

These experts choose materials, specify manufacturing techniques, and ensure the item can be made effectively. Their knowledge helps to save on expenses and limits manufacturing hazards. They also consider how a product will be maintained, delivered, and assembled. In a competitive market, businesses depend on knowledgeable industrial designers to provide goods that satisfy consumer demands while remaining on budget.

Bridging Function and Aesthetics with Product & Design Strategies

Product and design strategies are more than just visual appeal. They call for thoroughly investigating user behavior, market trends, and technical possibilities. A good product design should provide a smooth user experience and address a genuine need. This calls for knowledge of ergonomics, psychology, and even cultural tastes.

Consider production design, for instance. This stage of development guarantees that the final product not only works properly but also fits the brand’s identity and consumer expectations. Businesses that invest in solid product and design plans usually surpass their rivals because they make goods customers really like to utilize.

Real-World Example: How Industrial and Product Design Influence Manufacturing

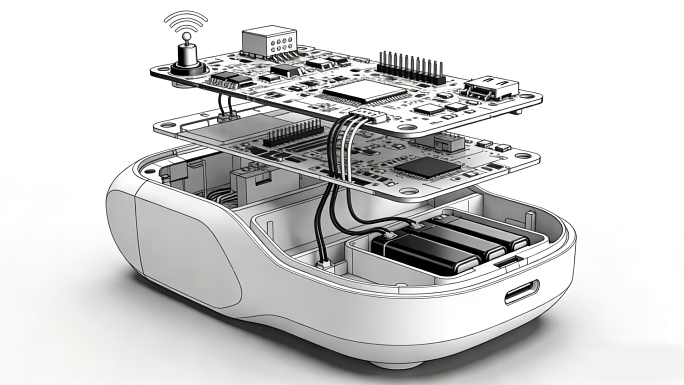

Let us look at a typical electrical device: a wireless earphone. Understanding what consumers value most—comfort, sound quality, battery life, and style—begins the industrial and product design process. Working on the form factor, industrial designers ensure the earphone comfortably fits in the ear while housing all the required parts. They select lightweight yet robust materials.

Simultaneously, the product and design team considers user interaction with the earbuds. This covers the package experience, charging techniques, and touch controls. The production design team guarantees that the design can be mass-produced without sacrificing quality.

Statistics indicate that in 2023, the worldwide market for wireless earbuds surpassed 310 million units, hence demonstrating how vital these design factors are. Businesses that successfully blend industrial and product design will grab a bigger portion of this expanding market.

The Impact of Technology on Industrial and Product Design

Technology has changed the way industrial and product design teams operate. Sophisticated design tools enable exact modeling and simulation. 3D printing lets designers quickly prototype their concepts in physical form within hours. Before manufacturing starts, virtual reality and augmented reality enable teams to see goods in the actual environment.

Automation is also important. With remarkable accuracy, robotic production lines can create very complicated items. This lowers personnel expenses and enhances consistency. For instance, laser cutting and CNC machining have made it feasible to build complex designs that were previously unfeasible or too costly.

Industry studies show that businesses that spend money on automated manufacturing and digital design tools experience up to 25% quicker product development cycles. This speed benefit lets them react more swiftly to consumer input and market changes.

Personalization and Customization in Modern Product Design

Today’s consumers want goods that mirror their personal tastes. In industrial and product design, personalization has become a significant trend. Whether it’s bespoke colours, engraved names, or configurable features, people want things that seem special to them.

This need has inspired fresh production methods, including mass customisation, which creates goods to order depending on consumer requirements. Industrial designers and production teams must cooperate to design flexible manufacturing systems that can manage this degree of customisation without increasing prices.

Personalization is a competitive edge, not only a fad. Studies indicate that 80% of consumers are more willing to buy from companies providing tailored experiences. Businesses that adopt this strategy stand out in competitive industries and foster more robust consumer loyalty.

Sustainability at the Intersection of Industrial and Product Design

Another field where industrial and product design converge is sustainability. Designers are increasingly opting for sustainable techniques and materials. From raw material acquisition to end-of-life recycling, they consider the whole lifecycle of a product. This comprehensive strategy minimizes environmental impact.

3D printing and other technologies help reduce waste by using only the required material for each component. Digital prototyping saves energy and resources by lowering the demand for physical samples. Businesses that prioritize sustainable design not only benefit the world but also satisfy the consumer’s need for eco-friendly goods.

Surveys show that 72% of buyers consider sustainability when deciding on purchases. This change in consumer behavior is driving more businesses to include environmentally friendly practices in their product and industrial design plans.

The Future of Industrial and Product Design

Industrial and product design’s future seems bright. Emerging technologies such as artificial intelligence, machine learning, and the Internet of Things are opening new opportunities. AI-driven design tools can provide the best design solutions by examining large volumes of data. Products with IoT can gather user data to enhance future designs.

Success will still depend primarily on cooperation. Market leaders will be businesses that dismantle silos between industrial design, product & design teams, and manufacturing design specialists. They will be better able to design durable, beautiful, valuable items.

The link between industrial and product design will only strengthen as technology develops. This junction is not only where design takes place; it’s also where creativity flourishes.

Conclusion

Product and industrial design are becoming intertwined disciplines. Their convergence powers contemporary manufacturing and product creation. Combining the accuracy of industrial design with the user-oriented approach of product & design strategies helps businesses to produce goods that satisfy genuine demands and stand out in crowded markets.

Every stage of development, from the industrial design center to the production floor, gains from this cooperative approach. The future of industrial and product design is full of interesting possibilities given technology developments and rising consumer desire for sustainable and tailored goods. Businesses that embrace.